- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200

-

Voltage:

-

380V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dession

-

Bag type:

-

Premade pouch

-

Usage:

-

Powder granule liquid

-

Packing speed:

-

Max:60bags/min

-

Keyword:

-

Safety

-

Main Function:

-

Weighing Forming Filling Sealing

-

Feature:

-

Easy Opperation

-

Filling Range:

-

Max. 1000ml

-

Bag width:

-

90-210mm

-

Bag length:

-

110-330mm

-

Air consumption:

-

0.7MPA

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

1200

-

Voltage:

-

380V 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dession

-

Bag type:

-

Premade pouch

-

Usage:

-

Powder granule liquid

-

Packing speed:

-

Max:60bags/min

-

Keyword:

-

Safety

-

Main Function:

-

Weighing Forming Filling Sealing

-

Feature:

-

Easy Opperation

-

Filling Range:

-

Max. 1000ml

-

Bag width:

-

90-210mm

-

Bag length:

-

110-330mm

-

Air consumption:

-

0.7MPA

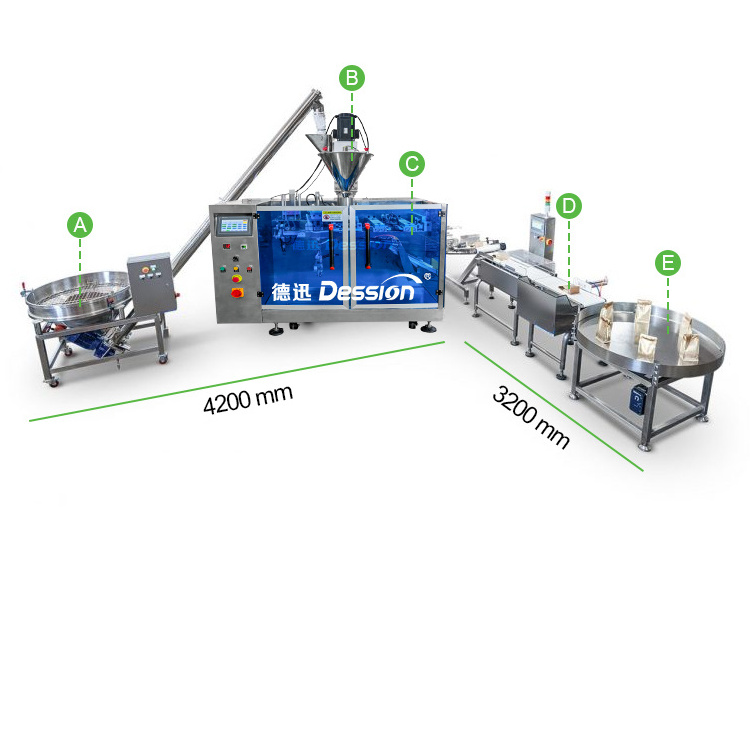

Automatic Horizontal Doypack Packing Machine

Full Automatic Powder Packing System

Dession new powder bagging system for premade bags. Engineered for a client packaging dry powder, this system is also the perfect solution for packaging other granule or liquid products where a premade bag is required.

Built specifically for the client’s bag sizes. This automated system conveys powder from a

Hopper

up to the

Powder Auger Powder Weigher

via a screw conveyor.

Once weighed, it passes into the

Horizontal Premade Bag Packing Machin

e where it is dispensed into premade bags before the top is sealed. Bags are then conveyed to the

Weight Check Weigher

to ensure each bag meets the preset weight tolerance before it is accumulated on a

Rotary Table

.

Unique system features include an integrated bag shaker to fully settle the product in the bag prior to sealing, and a product rejection system to prevent the accumulation of bags that are outside of the desired weight tolerance.

This integrated powder packaging system to weigh fill

up to 3000 bags per hour

to meet the needs of the most progressive retailers.

A ----- Powder Hopper with Screw Conveyor

B ----- Powder Auger Powder Weigher

C ----- Horizontal Premade Bag Packing Machine

D ----- Weight Check Weigher

E ----- Rotary Table

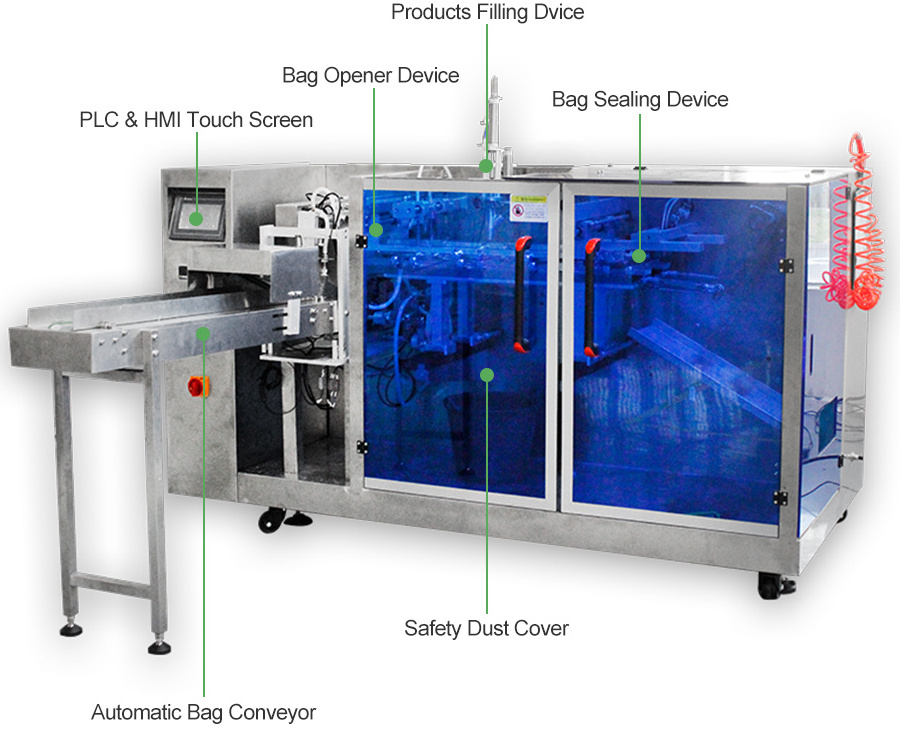

This packing machine automatically complete bag opening, measuring, filling, sealing, and can be configured with functions such as printing batch numbers according to customer requirements.

|

Model

|

DS-160

|

DS-210

|

DS-260

|

DS-320

|

|

Bag Width

|

80-160mm

|

90-210mm

|

150-260mm

|

200-320mm

|

|

Bag Length

|

100-210mm

|

110-330mm

|

150-400mm

|

150-500mm

|

|

Packing Speed

|

10-60 bags / min

|

10-50 bags / min

|

10-40 bags / min

|

10-30 bags / min

|

|

Filling Range

|

Max.300ml

|

Max. 1000ml

|

Max. 2000ml

|

Max. 3000ml

|

|

Power Supply

|

380V 50/60Hz 3KW

|

380V 50/60Hz 4KW

|

380V 50/60Hz 5KW

|

380V 50/60Hz 6KW

|

|

Air Consumption

|

0.5MPA

|

0.5MPA

|

0.7MPA

|

0.7MPA

|

|

Machine Size

|

1400*900*1050

|

2150*1350*1300

|

2450*1350*1350

|

2800*1350*1350

|

|

Machine Weight

|

600KG

|

900KG

|

1100KG

|

1500KG

|

If you want to know more details about the machine, or need us to provide you with a good solution and service, please contact me.

Powder Packaging System Working Process

Powder Transportation

The powder transportation stage involves the controlled transfer of the powder from a hopper screw to an auger powder weigher.

The hopper screw serves as a reliable feeding mechanism, ensuring a consistent flow of powder to the weigher. This controlled transfer helps maintain the desired product consistency and prevents overfilling or spillage.

Powder

Weighing Process

Once the powder reaches the auger powder weigher, precise weighing takes place. The auger powder weigher is a highly accurate system that measures the exact amount of powder required for each bag. It utilizes advanced technology and algorithms to ensure consistent and precise filling.

This stage is crucial for achieving the desired product weight and maintaining uniformity across all bags.

Premade Bag Filling Sealing

This stage of the process is characterized by high-speed operation, reliability, and precision.

Weighing Check

Weigher

Following the bag packing stage, the filled bags proceed to the weighing check weigher. This quality control mechanism plays a vital role in ensuring the accuracy of each bag's weight. The weighing check scale meticulously verifies the weight of each bag by comparing it to the desired target weight. Any variations or deviations are detected and flagged for immediate attention.

This rigorous quality control step ensures that only accurately filled bags progress to the next stage, minimizing waste and ensuring customer satisfaction.

Rotary Table for Finished Bag

The bags that have passed the weighing check stage move on to the rotary table process. The rotary table serves as a platform for organizing and arranging the filled bags, facilitating their subsequent handling and packaging.

The packaging effect is perfect, the weighing is accurate, the packaging error is small, the sealing is intact, and the airtightness is good.

Why Choose Us

1.

Strong Factory Strength.

A company with 15 years experience in factory, 8 years experience in international trade. Has a complete series of packaging equipment to provide customers with one-stop solutions. Packaging in bags, packaging in boxes, filling into bottles, metering filling devices, conveying devices and packaging materials, etc.

2.

High Quality Machine Delivery.

The machine is made of 304 stainless steel to ensure that the machine is sturdy and durable.

The electrical components of the machine are all world-renowned brands, including Mitsubishi, Siemens, Schneider, Panasonic, etc. To ensure the stable operation of the machine.

Our equipment has a number of patent certifications, CE certification, ROHS certification, IOS9001 certification, etc.

3.

Professional After-sales Team.

We promise:

1. Free replacement of machine parts within one year.

2. 24-hour online technical support.

3. On-site installation training service within 14 days.

Customer Praise

Years of foreign trade experience has allowed us to gain recognition and praise from customers all over the world.

Since the establishment of the company, we have traded in more than 100+ countries, especially the European and American markets, which have been well received.

FAQ

Q1:Do you have manual or operation video for us to know more about the machine?

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q2:How can I trust you for the first time business ?

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q3:Is engineer available to serve oversea?

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q4:How can we make sure about the machine quality after we put the order?

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Q5:Will you provides the door to door service?

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

Hot Searches