- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

33

-

Voltage:

-

100V / 200V ± 10% 50HZ / 60HZ

-

Current:

-

2-200A

-

Rated Capacity:

-

80%

-

Dimensions:

-

377*129*42mm

-

Use:

-

welding / repair

-

Power source:

-

Contravariant

-

Welding current:

-

5-200A

-

Duty cycle (20℃):

-

200A 60%/155A 100%

-

Floating voltage:

-

65V

-

Input voltage:

-

ACC 200V ± 10% 50HZ / 60HZ

-

Power:

-

4.5 KW

-

Welding gun cooling:

-

Built-in circulating water cooling

-

Screen:

-

10 inch touch screen

-

Programmable memory:

-

100 unit

Quick Details

-

Marketing Type:

-

Hot Sale 2023

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

XINDUN

-

Weight (KG):

-

33

-

Voltage:

-

100V / 200V ± 10% 50HZ / 60HZ

-

Current:

-

2-200A

-

Rated Capacity:

-

80%

-

Dimensions:

-

377*129*42mm

-

Use:

-

welding / repair

-

Power source:

-

Contravariant

-

Welding current:

-

5-200A

-

Duty cycle (20℃):

-

200A 60%/155A 100%

-

Floating voltage:

-

65V

-

Input voltage:

-

ACC 200V ± 10% 50HZ / 60HZ

-

Power:

-

4.5 KW

-

Welding gun cooling:

-

Built-in circulating water cooling

-

Screen:

-

10 inch touch screen

-

Programmable memory:

-

100 unit

Products Description

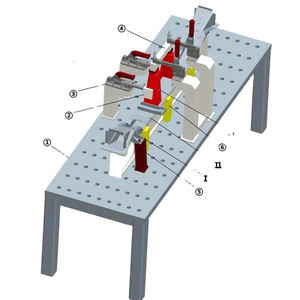

All - position automatic pipe welding equipment

XD-20W digital programmed welding power supply is composed of control system, power supply system and cooling water tank. It has the characteristics of digital, easy operation and reliability. The control system adopts an open and up gradable operating system to centrally set, store and synchronously control all functional parameters in the all-position welding. This power supply is specially designed and manufactured for thin-walled pipe/pipe welding. Mainly used in semiconductor, chemical, food, medicine,electronic pipeline and other industries.The overall design tends to be convenient,energy saving, intelligent, human-machine interaction. Reduced volume and weight by one third compared with the original split type. The integrated design is oriented to the construction with small space on sit.

Our Advantages

|

Product advantages

|

5、Real-time welding monitoring, simple and direct.

|

|

|

1、10-inch color screen, reasonable graphic design, in line with ergonomic operation habits

|

6、Light weight, makes the operation more efficient, more safety when working at height.

|

|

|

2、Siemens PLC control system, to ensure the rapid operation of welding process parameters, accurate and reliable. Low

maintenance cost in later stage.

|

7、Welding torch design exclusive patent technology can ensure the quality of welding.

|

|

|

3、Double cooling system, greatly improve the welding torch temporary load rate

|

8、With one key printing and automatic printing functions, built-in micro free maintenance printer.

|

|

|

4、Accumulated welding data for many years, and made direct call by summarizing big data.

|

9、The core components imported from Germany ensure the stability of the equipment.

|

|

|

5、Real-time welding monitoring, simple and direct.

|

|

|

Machine Parameters

Welding Effects

Hot Searches