- Product Details

- {{item.text}}

Quick Details

-

Power:

-

50-1000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

50000 kg

-

Product name:

-

Best Price Calculation Lime Rotary Kiln For Construction

-

Application:

-

Active Lime Plant

-

Capacity:

-

150-1000tpd

-

Spare Parts Supply:

-

Supply at lowest price

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Quality:

-

International Standard

-

Calcination material:

-

Limestone, Cement clinker

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNISHINE

-

Voltage:

-

220-480V

-

Power:

-

50-1000KW

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

50000 kg

-

Product name:

-

Best Price Calculation Lime Rotary Kiln For Construction

-

Application:

-

Active Lime Plant

-

Capacity:

-

150-1000tpd

-

Spare Parts Supply:

-

Supply at lowest price

-

Installation and trial:

-

Send Engineer

-

Factory Visit:

-

Invitation Letter

-

Design drawings:

-

Provided

-

Quality:

-

International Standard

-

Calcination material:

-

Limestone, Cement clinker

-

After-sales Service Provided:

-

Online support

|

Model |

Diameter of cylinder (mm) |

Length of cylinder (mm) |

Inclination (%) |

Capacity (t/h) |

Rotation speed (rpm) |

Power (kw) |

Weight (t) |

|

YZ1225 |

1200 | 25000 | 4 | 3 |

0.53-5.25 |

22 | 34 |

|

YZ1632 |

1600 | 32000 | 4 | 3.5 |

0.53-5.25 |

15 | 46 |

|

YZ1828 |

1800 | 28000 | 4 | 4 |

0.28-2.84 |

30 | 59 |

|

YZ1845 |

1800 | 45000 | 4 | 4.5 |

0.28-2.84 |

30 | 80 |

|

YZ1636 |

1600 | 36000 | 4 | 1.2-1.9 |

0.26-2.61 |

22 | 51 |

|

YZ1939 |

1900 | 3900 | 4 | 1.6-3.4 |

0.31-2.82 |

37 | 70 |

|

YZ2044 |

2000 | 44000 | 3.5 | 2.4-4 |

0.22-2.26 |

37 | 97 |

|

YZ2245 |

2200 | 45000 | 3.5 | 3.2-5.3 |

0.23-2.25 |

45 | 125 |

|

YZ2550 |

2500 | 50000 | 3.5 | 6.2-7.4 |

0.68-1.45 |

55 | 179 |

|

YZ2555 |

2500 |

55000 |

3 | 7.3-9.8 | 0.79-2.38 | 55 | 191 |

|

YZ2820 |

2800 |

20000 |

4 |

15-18 |

0.8-1.45 |

75 | 186 |

| YZ3028 | 3000 |

28000 |

4 | 18-23 |

0.8-1.45 |

75 | 180 |

| YZ3060 | 3000 | 60000 | 3.5 |

16-20 |

0.49-2.41 | 90 | 272 |

| YZ3226 | 3200 | 26000 | 4 | 22-27 | 0.8-1.45 | 90 | 185 |

| YZ3255 | 3200 | 55000 | 3.5 |

17-23 |

0.1-1.52 |

75 | 271 |

| YZ3529 | 3500 | 29000 | 4 |

28-40 |

0.16-1.38 |

110 | 238 |

|

YZ3560 |

3500 | 60000 | 3.5 | 28-40 | 0.65-2.25 | 125 | 347 |

| YZ4030 | 4000 | 30000 | 4 | 52-70 | 0.38-3.52 | 160 | 415 |

|

YZ4060 |

4000 | 60000 | 3.5 | 55-78 | 0.38-3.52 | 315 | 514 |

|

YZ4262 |

4200 | 62000 | 3.5 | 80-105 |

0.38-3.52 |

315 | 541 |

| YZ4565 | 4500 | 65000 | 3.5 |

110-140 |

0.38-3.52 |

420 | 609 |

| YZ4772 | 4700 | 72000 | 3.5 |

150-190 |

0.38-3.52 |

550 | 795 |

| YB1626 | 1600/1400 | 26000 | 4 | 0.7-11 |

0.41-3.85 |

18.5 | 38 |

|

YB1939 |

1900/1600 | 39000 | 4 |

2.2-2.7 |

0.27-2.58 |

22 | 60 |

| YB2245 | 2200/2000 | 45000 | 3.5 |

2.5-3.5 |

0.25-2.28 | 30 | 88 |

| YB2545 |

2500/2200 |

45000 | 3.5 | 4.5-6.2 | 0.25-2.18 | 45 | 102 |

| YB2845 |

2800/2500 |

45000 | 3.5 |

7.5-10 |

0.68-1.45 |

55 | 192 |

| YB3560 |

3500/3000 |

60000 | 3.5 |

23-32 |

0.65-2.28 | 125 | 310 |

Active lime rotary kiln

Capacity: 150-1000t/day

Applicable materials: Limestone, cement clinker, bauxite, aluminum hydroxide, chrome ore, etc.

Application: Main equipment for calcining active lime.

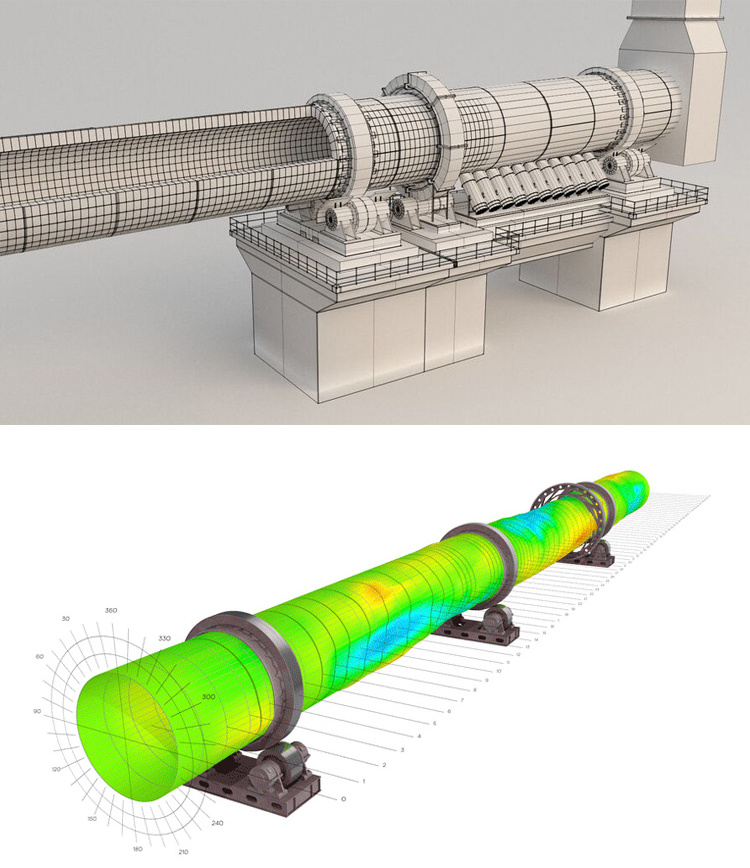

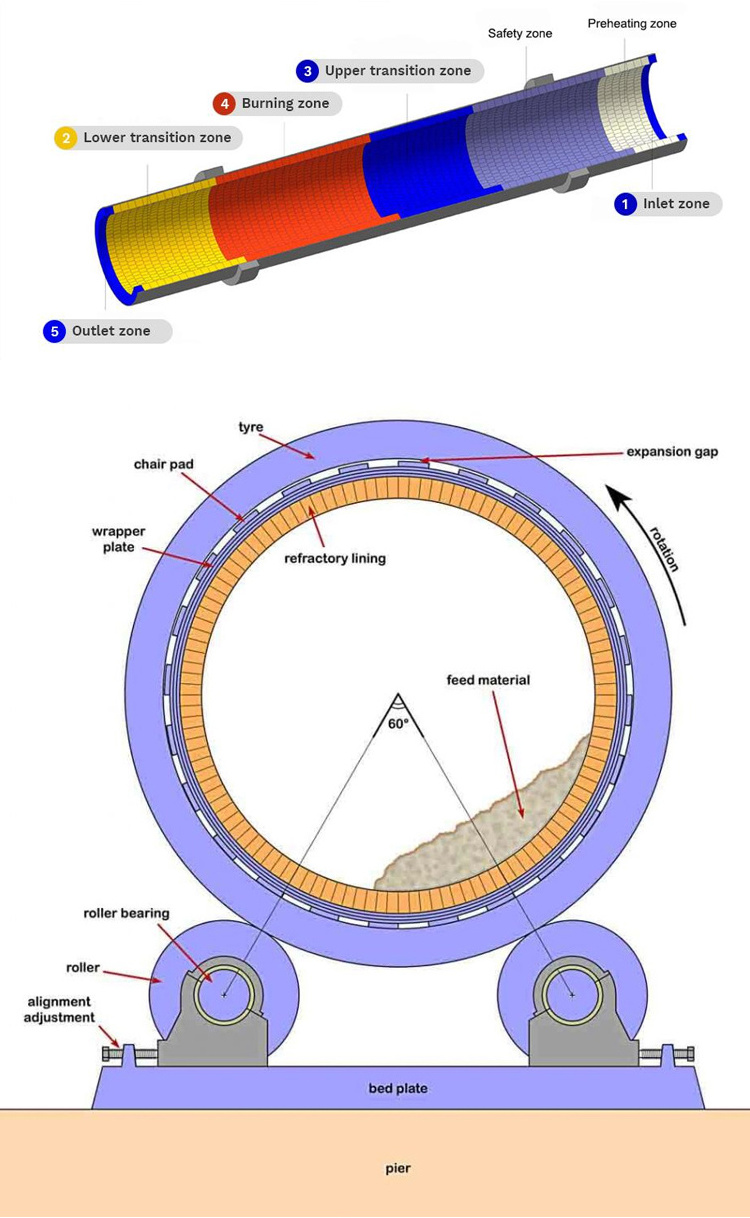

Brief Introduction: Lime rotary kiln is the main equipment for calcining active lime, which is composed of cylinder, supporting device, supporting device with hydraulic retaining wheel, transmission device, lubrication device, kiln tail sealing device and other components. It has the characteristics of simple structure, reliable operation and easy automatic control of production process.

Introduction

Lime rotary kiln is the main equipment for calcining active lime, which is composed of cylinder, supporting device, supporting device with hydraulic retaining wheel, transmission device, lubrication device, kiln tail sealing device and other components. It has the characteristics of simple structure, reliable operation and easy automatic control of production process.

Characteristics

1. High thermal efficiency

The material is heated uniformly and fully in the cylinder, and the heat transfer is rapid. On the other hand, the material and the gas flow in the reverse direction, and the heat is fully utilized. The exhaust gas passes through the preheater at the kiln end, and the heat is reused to dry the material, and the finished lime is taken out. The heat is converted into hot air by the cooler under the kiln head and then returned to the kiln, which greatly improves the thermal efficiency of the kiln.

2. Wide range of raw material size

When using lime rotary kiln equipment to calcinate limestone, the raw material has a wide range of particle size and can calcinate limestone below 10mm, which not only improves the utilization rate of mine resources, but also has the effect of environmental protection and energy saving.

3. Good quality of finished products

The fuel does not directly contact the material, and the sulfur in the fuel cannot easily enter the lime. Therefore, the lime burned by the lime rotary kiln has a low sulfur content, which is beneficial to desulfurization in steelmaking.

4. Simple operation and high efficiency

The operation of the lime rotary kiln system is easy to master, and the observation is intuitive and easy to ensure that users can put into production in a short time. Related equipment can be designed according to customer production requirements, and the work efficiency is high.