- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

kj415

-

Machine::

-

CNC

-

CNC Machining Tolerance::

-

0.003 to 0.005mm

-

Design software::

-

UG PROE CAD

-

Cavity::

-

single multiple

-

Mould Base::

-

LKM,HASCO,DME

-

Runner::

-

Hot/cold

-

Injection Mould running:

-

Full automaticity

-

Injection Mould features:

-

High classic very mature plastic mould structure

-

Equipments:

-

CNC, Electric Spark Machine(WEDM-LS),Injection Machine

-

Mould Steel:

-

NAK80,2738,2316,H13,718,S136,SKD61,P20,etc

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

kaiji

-

Model Number:

-

kj415

-

Machine::

-

CNC

-

CNC Machining Tolerance::

-

0.003 to 0.005mm

-

Design software::

-

UG PROE CAD

-

Cavity::

-

single multiple

-

Mould Base::

-

LKM,HASCO,DME

-

Runner::

-

Hot/cold

-

Injection Mould running:

-

Full automaticity

-

Injection Mould features:

-

High classic very mature plastic mould structure

-

Equipments:

-

CNC, Electric Spark Machine(WEDM-LS),Injection Machine

-

Mould Steel:

-

NAK80,2738,2316,H13,718,S136,SKD61,P20,etc

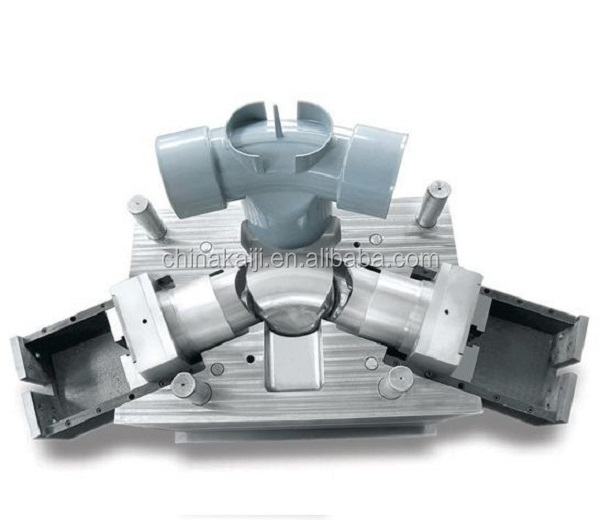

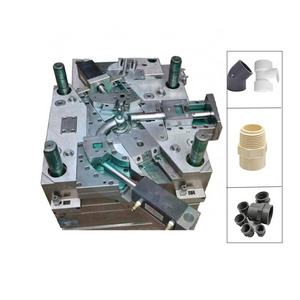

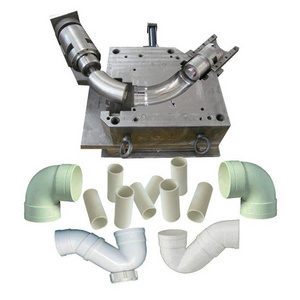

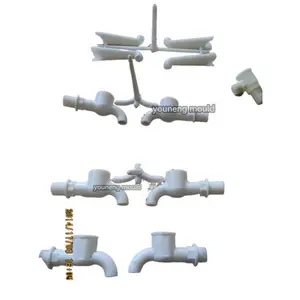

1 . Detailed description of Custom Plastic Mould:

|

name |

Custom Plastic Mould |

|

mould material |

45# 50# 718 2738 P20 S136 etc |

|

mould design |

3D/2D |

|

design days |

3-5 days |

|

mould life |

300.000-3.000.000 |

|

plastic material |

PE PC PS PP ABS PVC etc. |

|

injection system |

pin-point gate |

|

payment |

40% of deposit by L/C T/T 60% of balance by L/C T/T |

There are three levels of mold quality for your option.

Option A: Level A quality(Highest Level Quality)

Mould Base: LKM,45# Steel

Core/Cavity: S136+Becu

Mould spare parts: SKD

Hot Runner: YUDO

Mould Life:1,000,000 shots

Option B: Level B quality(Middle Level Quality)

Mould Base: 45# Steel,self-made

Core/Cavity: 718H

Mould spare parts: Jinghong, China

Hot Runner: Zhenghao,China

Mould Life:800,000 shots

Option C: Level C quality(Lowest Level Quality)

Mould Base: 45# Steel,self-made

Core/Cavity: P20

Mould spare parts: Jinghong,China

Hot Runner: Zhenghao,China

Mould Life:500,000 shots

Attention pls:

Price varies in different quality level. When you send us the mold inquiry, please offer the following information:

1)Quality level you choose: Level A/Level B/Level C

2)Product Photo

3)Product Dimension

2 . Custom Plastic Mould making process

|

Processing |

Time |

|

Prepare Steel |

5 days |

|

CNC Machining |

10 days |

|

Drill |

8 days |

|

Heat treatment |

6 days |

|

High speed CNC Machining |

7 days |

|

Assembling and Fitting |

6 days |

|

Polishing |

6 days |

|

T1 mould test |

2 days |

Total: It is 50 days for first mould testing after mold design is confirmed.

3 . Custom Plastic Mould quality control

For the Q/C of mold, there are 3 steps:

1.Mold Material Q/C

- Mold Steel Checking(Hardness, flaw detection)

- Mold Standard Spare Parts Checking(hardness, size, flaw checking)

2.Mold Making Process Q/C

- design checking (part design, mold design, mold engineering drawing)

- Each part of mold’s size checking after machining according to 2D drawing

- mold testing(check mold running condition)

3. check with customer’s requirement again before mold shipping.

4 . Custom Plastic Mould pack and shipping

Anti-rust oil is painted first, then Plastic film, and finally Wooden Case.

Sent together with the mold:

a) Mold manual instruction

b) engineering drawing in flash disk

c) one more set of mold spare parts:heater,ejector pin,bush,water nozzle,water pipe,hanging ring.

5 . Custom Plastic Mould maintenance

a)When the mold is vacant, spray the anti-rust oil

b)To clean the gate and cooling system regularly

c)Avoid to use recycled material if the mold is suitable for virgin material only

6 . Custom Plastic Mould After-Sale Service

a)Engineering and one interpreter can be sent to customer’s factory for first running.

b)one-year after-sale technique support .

Factory Advantage:

Taizhou Kaiji Plastic Mould Co.,ltd has a strict quality control system and high efficent work team.We are specialized in manufacturing plastic injection moulds,including commdity moulds,home appliance moulds,vechicle and auto part moulds.

The workshop is well equipped with the latest machines and production facilities of the injection moulds. We've set up a perfect CAD/CAM/CAE system and got ISO9001 certificate.

We have a strong technical team,advanced mould processing system,and professional workers.We wish to provide the best service at all times at minimum cost.

Welcome to create a nice future with us.

For more convenient contact, please add whatsApp 008613750667050, we will reply you within 24 hours!