The traditional process usually uses two steps separately to achieve drying in EPS after washing, namely centrifugal dewatering equipment and drying equipment. Weiliang, only needs one machine ( WLG EPS DRYER MACHINE ) to achieve dewatering and drying at the same time, shorten the production line.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

1270 KG

-

Product name:

-

WLG Dryer Machine

-

Material:

-

Stainless steel SUS304, 316L

-

Model:

-

D525/D650/D850/D1050

-

Reference Air Flow (m3/h):

-

6500---20300

-

Reference Capacity EPS Beads(Kg/h):

-

2500---12000

-

Mesh size:

-

0.15mm

-

Water usage:

-

13m/hr-----114m/hr

-

Motor power:

-

15KW----37KW

-

Keyword:

-

EPS Dewatering Dryer Machine

-

Certification:

-

ISO; CE

Quick Details

-

Type:

-

LINEAR

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Weiliang

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Depends on the model

-

Weight:

-

1270 KG

-

Product name:

-

WLG Dryer Machine

-

Material:

-

Stainless steel SUS304, 316L

-

Model:

-

D525/D650/D850/D1050

-

Reference Air Flow (m3/h):

-

6500---20300

-

Reference Capacity EPS Beads(Kg/h):

-

2500---12000

-

Mesh size:

-

0.15mm

-

Water usage:

-

13m/hr-----114m/hr

-

Motor power:

-

15KW----37KW

-

Keyword:

-

EPS Dewatering Dryer Machine

-

Certification:

-

ISO; CE

Product Description

WEILIANG

WLG Dryer Machine

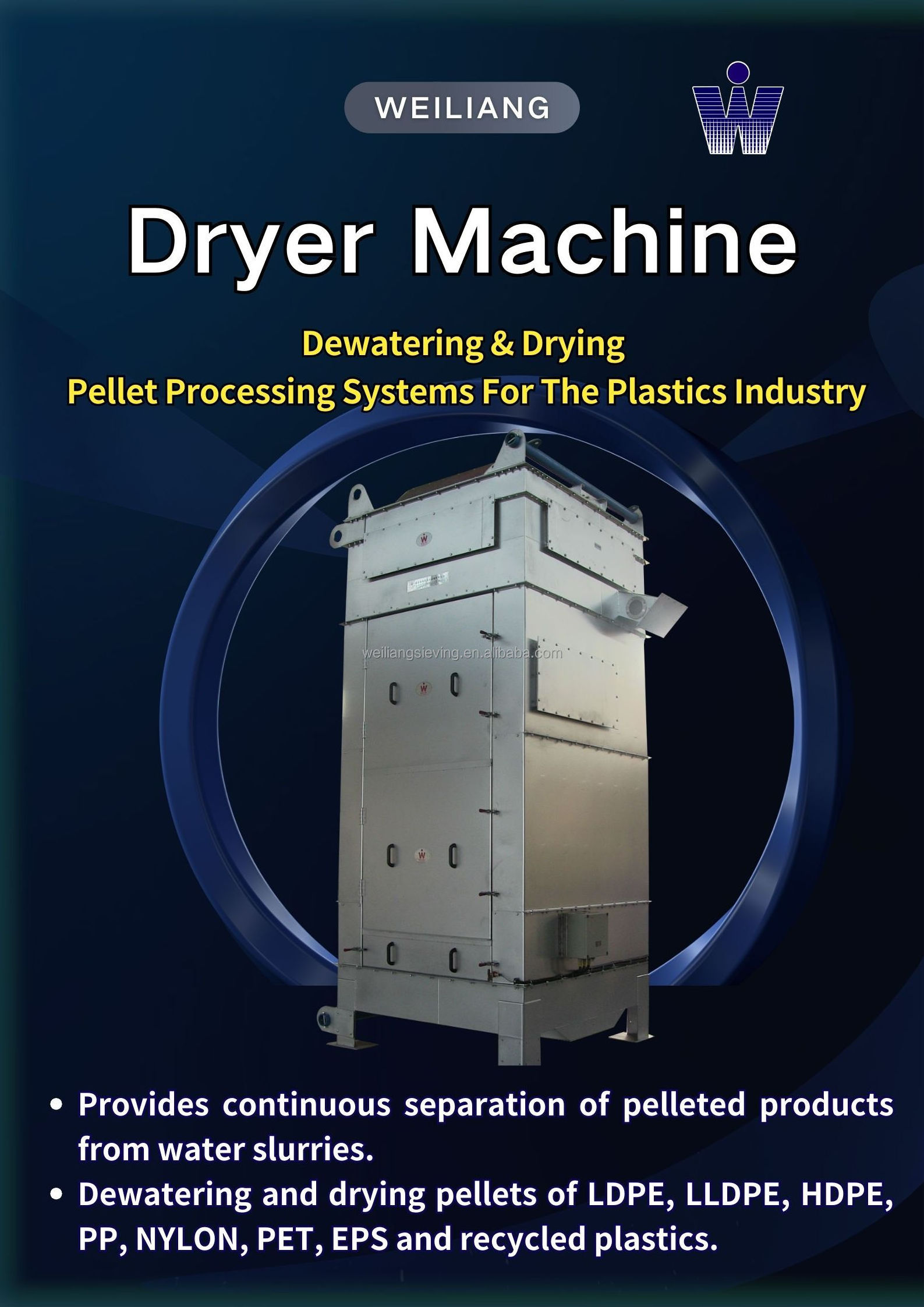

The WLG Dryer Machine provides continuous separation of pelleted products from water slurries. The whole drying process takes only a few seconds, the final material will be discharged quickly, and the surface moisture content of the EPS pellets after dried is as low as 0.05%. It is well suited for dewatering and drying pellets of LDPE, LLDPE, HDPE, PP, NYLON, PET, EPS and recycled plastics

WEILIANG Intelligent Vibrating Screen Super Factory

Details and Advantages

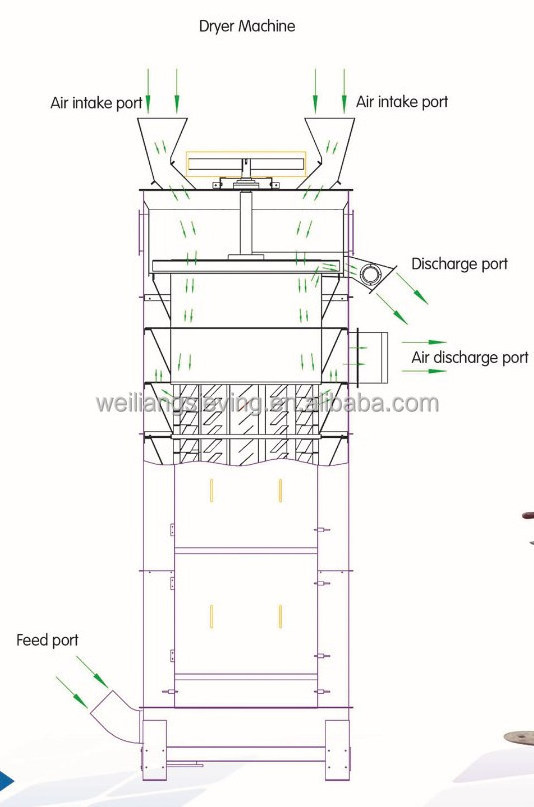

Principle

The WLG Dryer Machine protects against product contamination, reduces maintenance intervals, and maximizes dryer output. Final drying is accomplished by spinning off the moisture through the centrifugal action of the vertical rotor located in the center of the dryer. Both the speed of rotation and the design of the lifters inside the rotor cause the pellets to move between lifters and screens while being conveyed by centrifugal action up the dryer rotor in a helical path. The rotor consists of impeller blades extending from the bottom to the top of the dryer. The water is separated through the screens and the pellets are continuously conveyed into the upper section of the dryer, where they are discharged from the outlet.

Highlight

* Unitized tubular rotor construction, higher drying capacity

* Vibration free performance, self cleaning rotor

* Easy access for screen changesand cleaning

* Reduced downtime for major service

* Vibration free performance, self cleaning rotor

* Easy access for screen changesand cleaning

* Reduced downtime for major service

HOW EPS SIEVING

Weiliang YBS TUMBLER SCREEN with three-dimensional adjustment system can classify EPS resin into different size

with high precision and large capacity. EPS resin is usually divided into five sizes.

Sometimes customers will do secondary screening of oversize EPS resin (e.g. larger than 1.4 mm) coming

out of the YBS tumbler screen. Weiliang S49 VIBRATING SCREEN can be set behind the YBS tumbler screen in the production line to get more size of EPS resin.

out of the YBS tumbler screen. Weiliang S49 VIBRATING SCREEN can be set behind the YBS tumbler screen in the production line to get more size of EPS resin.

Technical Parameters

Applications

WEILIANG WLG Dryer Machine mainly used in the plastics industry, such as the dewatering and drying of EPS,LDPE, HDPE, LLDPE, ABS, PVC, PE, PP, PS, PA, Nylon etc...

Packing & Delivery

Inner packaging: Stretch film for machine

Outer packaging: Standard export wooden box

Hot Searches