- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

220V50HZ/380V50HZ

-

Power:

-

15KW

-

Dimension(L*W*H):

-

According to specific machine model

-

Weight:

-

6000 kg

-

Warranty:

-

1 Year

-

small toilet paper making machine Item:

-

Tissue toilet making machine

-

toilet paper machine Raw material:

-

Waste paper, waste carton, jumbo roll, virgin pulp

-

toilet papermachine Output paper:

-

Toilet Paper Tissue Paper Napkin Paper Kraft paper

-

toilet paper machine Capacity:

-

1-10tons/day

-

small toilet paper machine Application:

-

Paper making field

-

Paper machine Width virgin paper:

-

600-3000mm

-

Tissue paper machine Pulping processing:

-

Support

-

Paper machine Technical service:

-

Support

-

Toilet paper machine Installing date:

-

1-2 months

-

Machine make toilet paper Worker number:

-

5-8 people

Quick Details

-

Production Capacity:

-

100 m/min

-

Product Type:

-

Tissue toilet making machine

-

Processing Type:

-

Tissue toilet making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shunfu

-

Voltage:

-

220V50HZ/380V50HZ

-

Power:

-

15KW

-

Dimension(L*W*H):

-

According to specific machine model

-

Weight:

-

6000 kg

-

Warranty:

-

1 Year

-

small toilet paper making machine Item:

-

Tissue toilet making machine

-

toilet paper machine Raw material:

-

Waste paper, waste carton, jumbo roll, virgin pulp

-

toilet papermachine Output paper:

-

Toilet Paper Tissue Paper Napkin Paper Kraft paper

-

toilet paper machine Capacity:

-

1-10tons/day

-

small toilet paper machine Application:

-

Paper making field

-

Paper machine Width virgin paper:

-

600-3000mm

-

Tissue paper machine Pulping processing:

-

Support

-

Paper machine Technical service:

-

Support

-

Toilet paper machine Installing date:

-

1-2 months

-

Machine make toilet paper Worker number:

-

5-8 people

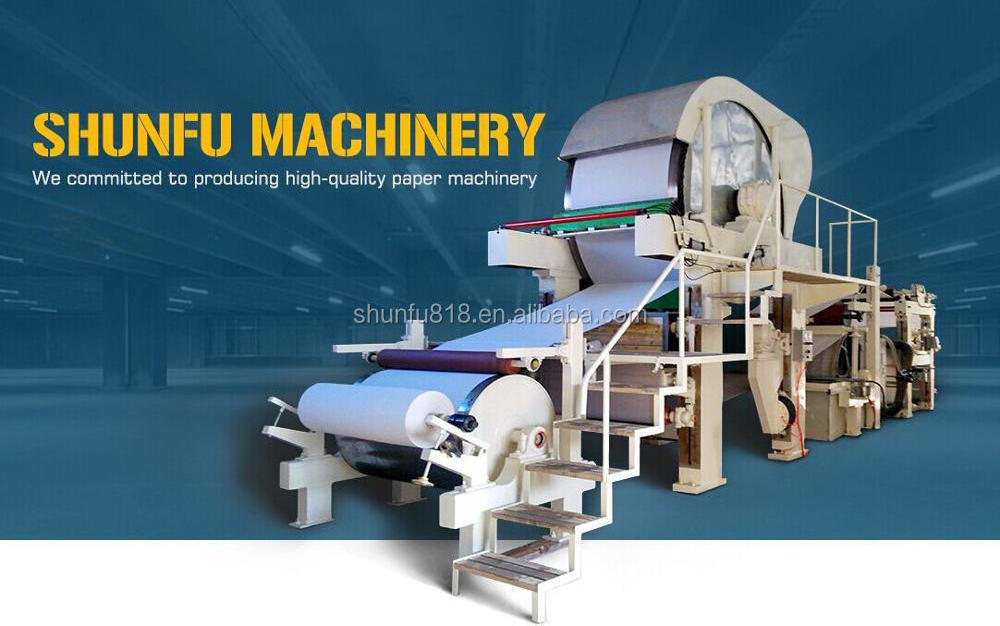

2400mm soft tissue toilet paper making machine, cotton pulp towel manufacturing production line

P art 1 . Outlook of Tissue toilet making machine

Tissue toilet making machine are many models and different capacity production line, Such as 787/1092/1575/1800/2000/2400/3600 model and so on. Toilet/tissue paper making machine is a set of production line from waste paper recycled to finished paper, also called: paper machine,tissue machine, tissue rewinder,paper making machine,toilet roll rewinder,toilet roll machine,toilet tissue machine.

P art 2 . Technical for Tissue toilet making machine

| Raw material | Waste paper; wood pulp board |

| Output paper style | Toilet paper; tissue paper |

| Paper weight | 15-60g/m2 |

| Paper width | 600-3000mm |

| Width of cylinder mould | According to actual |

| Capacity | 1-10T/D |

| Design speed | 120-200m/min |

| Work speed | 70-100m/min |

| Design Standards | CNS export equipment |

| Machine specifications | Upside down slurry form |

Part 3 . Processing for Tissue toilet paper making machinery

Raw material ⇒ Pulp ⇒ Screening purification ⇒ Pulp tank ⇒ Concentration ⇒ Pulp tank ⇒ Grinding ⇒ Slurry tank ⇒ Pulp box ⇒ Paper machine ⇒ Jumbo roll

Part 4 . Tips for Tissue toilet paper making machinery

|

No. for Tissue toilet paper making machinery |

Questions for Tissue toilet paper making machinery |

|

1 |

How many tons per day you want to produce about small toilet paper making machine? |

|

2 |

How many width you want to finished paper about small toilet paper making machine? |

|

3 |

Which kind of boiler you want to use?(The machine need to use boiler, the boiler fuction is produce hot steam to drying paper, the boiler have 3 kinds: coal boiler and gas boiler and diesel boiler, you choose one) |

Part 1 . Outlook of Toilet rewinding machine

Toilet paper rewinding machine according to the different degree of automation, can be divided into automatic toilet paper roll machine and semi-automatic toilet paper roll machine. Automatic toilet paper roll machine is a computer programming, semi automatic is PLC computer programming control.

Part 2 . Technical of Toilet rewinding machine

| 1. Equipment installed power: 3.0kw (380V or 220V, 50Hz) |

| 2. Cutting Machine Power: 1.5kw (380V or 220V, 50Hz) |

| 3. Winding Speed : 80-120 m / min |

| 4. Rewinding diameter (mm): 150mm |

| 5. Dimensions (m): 5X2.2X1.3 (length x width x height); |

| 6. Equipment Weight: 2.0T |

Part 3 . Features of Toilet rewinding machine

a. Patented-tech rewinding roller, make coreless paper rolls rewinding less weinkles and look better.

b. Servo motor controls web-break (abrupt acceleration) when the log is almost finished,decreasing failure rate and maintenance cost

c. High-precision NC machined large diameter blade shafts, German blade, Siemens high-class CNC system, guarantee perforation accuracy and clearness, and the finest tightness

d. Could adjust the perforating size at will;

Part 4 . Processing of Toilet rewinding machine

|

No. for Paper core machine |

Feature for Paper core machine |

|

1 |

Adopted PLC logic control system. |

|

2 |

Main motor is adopt vector type of high torque inverter for speed regulate |

|

3 |

There is a remote controller for easy operating(to stop or slow down the machine when lacked paper). |

|

4 |

Adoptd double size gluing and independent stainless steel gluing box,with imported silicone tube. |

Part 2 . Technical parameters

| Winding diameter | 20--200mm | Paper roll | 3-16 layers |

| Reel speed | 3-16m/min | Wall thickness | 1-8mm |

| Transmission mode | Automatic tensioning and anti off type chain transmission | Control way | Multi point operation panel |

| Winding head | 2 heads Single belt | Worker | 2 people |

| Coating method | Double side automatic glue | Winding foxed mothod | lamping type + flange type bidirectional locking |

| Cutting mothod | Single round knife synchronous automatic cutting | Definite form | Infrared precise fixed length |

| Host power | 7.5KW | Host rate | WPO 1:30 |

| Auxiliary power | 0.37KW+0.25KW | Speed control | Computer frequency conversion |

| Host size | 2600*1700*1600 | Power | 380V RSTN |

Part 3 . Tips of Paper core machine

Before we quote the price to you, please kindly confirm related technical data for paper tube, we will make quotation to you one to one. They include:

- The inner diameter

- The Max Thickness

- The Length

Part 1 . Technical of Paper napkin machine

|

Produce speed |

400-800pcs/min. |

|

Folding size |

190*190mm |

|

Unfolding size |

380*380mm |

|

Jumbo roll width |

380mm |

|

Jumbo roll diameter |

1200mm |

|

Jumbo roll specification |

double layer16-30g/m2 |

|

Equipment power |

4.1KW (380V 50HZ) |

|

Equipment weight |

about 1.2 T |

|

Equipment over size(L*W*H) |

3.3×1×1.2m |

Part 2 . Show of Paper napkin machine

Napkin paper machine is for bobbin paper into rectangular or square napkin paper after embossing, folding, electronic counting, cut into neat. The production process only need one time. The device can automatically embossing and folding, without artificial folding.

Part 3 . Tips of Napkin paper machine

- Whats size you want to produce napkin paper?(Unfolding size)

- You want to make napkin paper with printing or not?

Part 1 . Outlook of Facial Tissue Paper Machine

New design embossed facial tissue box paper machine is cut by the knife roll after cutting the base paper,fold into a chain of rectangular croww tissues. this embossed facial tissue box paper machine adopts vacuum suction,automatic counting function stack,with a high speed,neatly folded,and easy operation.

Part 2 . T echinical parameter of Facial Tissue Paper Machine

| Products size | 200×200±2mm |

| Base width | 2200mm |

| Dimensions | 5150*1300*1920mm |

| Paper diameter | Φ1100mm(other sizes are available) |

| Paper core inner diamater | 76.2mm |

| Speed | 0-80m/min |

| Embossing device | Steel to steel embossing |

| Embossing roller end | Felt roll,wool roller,rubber ruooler,steel roller |

| Controller | Electromagnetic speed |

| Blank lines | Steel on steel,the independent tregulator |

| Vacuum system | 7.5KW |

| Host power | 3KW |

| Use of power | Frequency control,electromagnetic governor |

Part 1 . Description for Egg tray machine

Egg tray machine equipment mainly uses waste paper,waste carton as raw materials. By smash pulp, vibrating pulp, grinding pulp and forming pulp, the forming machine adsorbs the pulp by vacuum type with some necessary chemicals.

Part

2

. Features of Egg Tray Machine

|

No. for Egg tray machine |

Feature for Egg tray machine |

|

1 |

Full automatic running according to setting |

|

2 |

Global famous brand of electric parts make stable running |

|

3 |

Optimized design with new technology, leading to high efficiency |

|

4 |

Perfect malfunction checkout system and motor protecting system guarantee safe running. |

|

5 |

Double cylinder balancing injecting |

|

6 |

High-performance, low-noise oil pump |

|

7 |

High-torque oil-motor pre-plasticizing |

|

8 |

Multi-step pressure and speed adjusting |

|

9 |

Five-pivot double-toggle mold locking computer-control with Chinese or English show |

Part 3 . Shunfu Introduction

Qinyang City Shunfu Paper Making Machinery Co., Ltd.

Founded in 1988 May, we are the factory of specializing in the production paper making machinery, pulping equipment and paper processing equipment, these years we committed to the development of high-quality, high efficiency, energy saving, environmental protection new products, service in paper making machinery industry, is a collection of scientific research, production in one of technology enterprise.

More than 20 years, the rapid development of enterprise, Production capability and production level rises ceaselessly, cale of production expands with each passing day, all products have passed ISO9001: 2008 quality management system certification, many times awarded the contract,observe the credibility of enterprise.

Production of paper making equipments re sold throughout the country over 20 provinces and areas, and exported to

Vietnam, Burma,Uzbekistan,Russia ,Kyrgyzstan, Nigeria, Ukraine, Botswana, Libya, Algeria, El Salvador , Lebanon, Moldova, Bolivia, Egypt, South Africa and other countries.The trust and praise by the user.

The most of customer usually very concerned this quesion: Can I visit your factory . Our answer is: Of course. So welcome to coming our Shunfu Factory. In order to let you know more about lines for coming our factory, now we desighed some lines for our further customers.

|

Line for visiting factory |

Specific guide line |

|

LINE 1 |

If you arrive in Guangzhou, you can take the plane or the high-speed rail to Henan, Zhengzhou, about 1500 kilometers. We'll have someone pick you up in Zhengzhou.

|

|

LINE 2 |

If you arrive in Beijing, you can take the plane or the high-speed rail to Henan, Zhengzhou, about 700 kilometers. We'll have someone pick you up in Zhengzhou.

|

|

LINE 3 |

If you arrive in Yiwu, you can take the plane or the high-speed rail to Henan, Zhengzhou, about 900 kilometers. We'll have someone pick you up in Zhengzhou.

|