- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Customised

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIMING MACHINERY

-

Voltage:

-

as requirement

-

Dimension(L*W*H):

-

16*1.3*0.9M

-

Weight:

-

5000 kg

-

Feeding width:

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

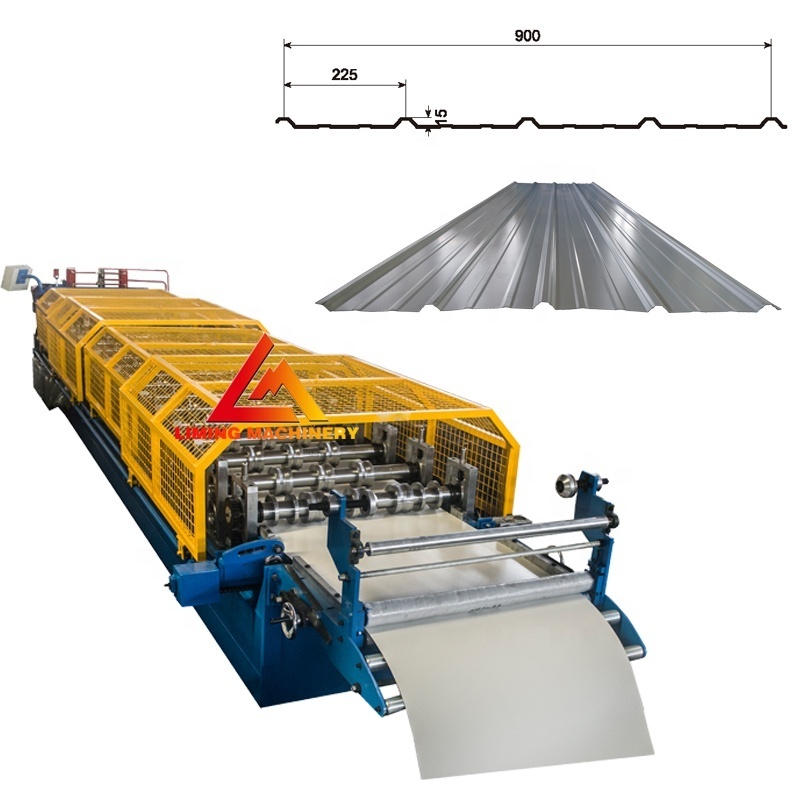

Xiamen Liming steel roof roll forming machine

-

Raw material:

-

PPGI

-

Product name:

-

Roof Tile Xiamen Roll Forming Machine

-

Usage:

-

Roofing Accessories

-

Color:

-

Customised

-

Control system:

-

PLC Control System

-

Cutting type:

-

Hydraulic Cutting System

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15-30m/min

-

Rolling thinckness:

-

Customised

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LIMING MACHINERY

-

Voltage:

-

as requirement

-

Dimension(L*W*H):

-

16*1.3*0.9M

-

Weight:

-

5000 kg

-

Feeding width:

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Xiamen Liming steel roof roll forming machine

-

Raw material:

-

PPGI

-

Product name:

-

Roof Tile Xiamen Roll Forming Machine

-

Usage:

-

Roofing Accessories

-

Color:

-

Customised

-

Control system:

-

PLC Control System

-

Cutting type:

-

Hydraulic Cutting System

PRODUCT SPECIFICATIONS

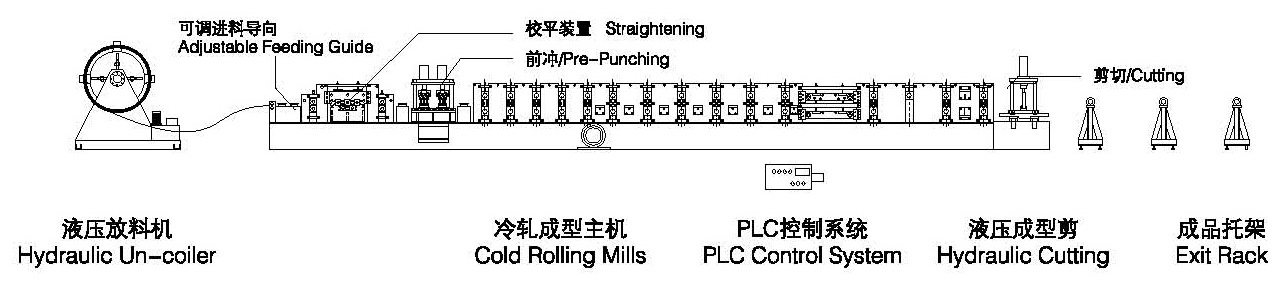

Roll Forming Machine Process

Uncoiling --- Material Feeding --- Roll Forming --- Step Making --- Automatic Cutting --- Products Receiving

|

TYPE

|

Roll former for roofing

|

|

SHEARING THICKNESS

|

Up to Max. 0.8mm

|

|

THICKNESS

|

0.4mm-0.8mm

|

|

FRAME DESIGN

|

Wall-plate-frame-design /New-stand-frame-design

|

|

MATERIAL OF FORMING ROLLER

|

45# steel, CNC lathes, Hard Chrome Coated

|

|

SHAFTS DIAMETER

|

Φ75/Φ95mm

|

|

MAX.LINE SPEED OF ROLL FORMER

|

15m-40/min (Higher speed is available, depends on the specification required by the buyer)

|

|

MATERIAL OF CUTTING BLADE

|

Cr12, hear treatment

|

|

ELECTRIC STANDARD

|

380V /50Hz/3PH or as per customer's requirements

|

|

MAJOR COLOR OF MACHINE PAINTED

|

RAL 5015 (Blue) or as per customer's requirements

|

1. The system is

easy to use and operate .

2. The surface of the finished product is very

smooth and beautiful

, without any scratches on the surface.

3. It can

work continuously

to ensure the progress of your project

4. The average speed can reach 4

0

m/min

, If you need to increase the speed of your equipment, please contact us.

Our Advantages

the moving column gantry five-face machining center

In June 2022, our company officially opened the moving column gantry five-face machining center. gZU40Mx130 is a gantry frame integral moving gantry milling and boring machine, which can be equipped with a variety of attachment iron head, and the parts can be finished five-face machining in one clamping. The product inherits the advantages of traditional gantry machine base frame with strong rigidity, symmetrical structure and strong stability, and introduces the international advanced design concept with fixed table and moving gantry frame, which is more suitable for processing of oversized and overweight parts. The main features are the use of the gantry super frame to achieve a large machining range, good rigidity, strong shock absorption, good stability and good dynamic characteristics.

vertical machineining center

width of working face on working table:70 mm

length of working face on working table:1400 mm

milling planner

plane & cut length: max 9000 mm

plane & cut width: max 2000 mm

Hot Searches