- Product Details

- {{item.text}}

Quick Details

-

Application:

-

road,parking, dam etc., retaining wall and road construction

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BPM GEOSYNTHETICS

-

Height:

-

50mm~250mm

-

Thickness:

-

1.0-1.7mm

-

Surface:

-

Textured Smooth

-

Certificate:

-

CE ISO14001 ISO9001

-

Package:

-

Plastic Packing Belts

-

WELDING DISTANCE:

-

330mm-1000mm

-

Color:

-

Black Yellow White Green

-

Model Number:

-

Geocell

-

Keyword:

-

HDPE geocell

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

road,parking, dam etc., retaining wall and road construction

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BPM GEOSYNTHETICS

-

Height:

-

50mm~250mm

-

Thickness:

-

1.0-1.7mm

-

Surface:

-

Textured Smooth

-

Certificate:

-

CE ISO14001 ISO9001

-

Package:

-

Plastic Packing Belts

-

WELDING DISTANCE:

-

330mm-1000mm

-

Color:

-

Black Yellow White Green

-

Model Number:

-

Geocell

-

Keyword:

-

HDPE geocell

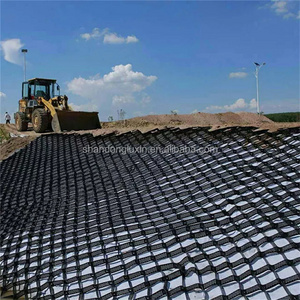

Product Introduction

HPDE Geocell is the three dimensional cellular confinement product which features lower cost, easy deployment, high strength and permeability. BPM high quality HDPE geocell is made of high density polyethylene (HDPE) and jointly welded by ultrasonic technology to ensure consistency, resistance to erosive forces. BPM geocells widely used in construction for erosion control, soil stabilization on flat ground, shorelines, steep slopes, multi-layered retaining walls, channel protection and structural reinforcement for heavy duty load support roads and earth retention.

Product Specifications

|

Product Type

|

Height(mm)

|

Welding Distance(mm)

|

Thickness(mm)

|

Tensile Strength of Welding Points(N/cm)

|

Tensile Strength of Connection of Cells(N/cm)

|

Tensile Strength at Yield of Each Sheet(MPa)

|

|

Smooth and Not Perforated

|

50≤H≤250

|

330≤A≤1000

|

1.0~1.4

|

≥100

|

≥120

|

≥20

|

|

Smooth and Perforated

|

50≤H≤250

|

330≤A≤1000

|

1.0~1.4

|

≥100

|

≥120

|

≥20

|

|

Textured and Not Perforated

|

50≤H≤250

|

330≤A≤1000

|

1.5~1.7

|

≥100

|

≥120

|

≥20

|

|

Textured and Perforated

|

50≤H≤250

|

330≤A≤1000

|

1.5~1.7

|

≥100

|

≥120

|

≥20

|

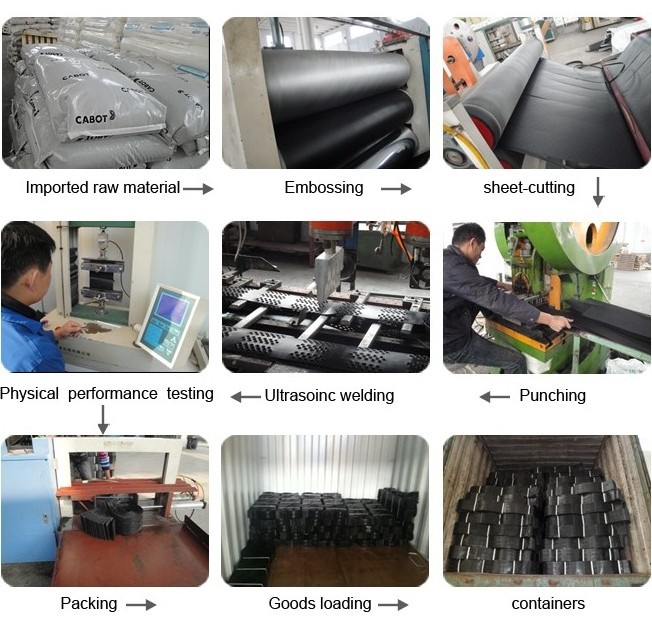

HDPE Geocell Production Process

The main HDPE geocell production processes include virgin HDPE resin sourcing, geocell formation and embossing, geocell sheet cutting, honeycomb structure punching, ultrasonic welding, physical performance testing, pacaking and loading.

HDPE Geocell Applications

*

Load support

: Solve unacceptable road, parking and yard surface problems.

* Slope protection : Create a stable environment for long-term sustainability of embankment material.

* Channel protection : Ensure stability and protection of channels exposed to all types of erosive conditions.

* Vegetated retaining walls : including steepened slopes, retaining walls, gravity walls and so on.

* Shorelines : Provide unique solutions to prevent erosion problems caused by water contact, surface flow and wave action.

* Slope protection : Create a stable environment for long-term sustainability of embankment material.

* Channel protection : Ensure stability and protection of channels exposed to all types of erosive conditions.

* Vegetated retaining walls : including steepened slopes, retaining walls, gravity walls and so on.

* Shorelines : Provide unique solutions to prevent erosion problems caused by water contact, surface flow and wave action.

Packing & Delivery

Our customers

Contact us

If you are interested in our products and company,

Please feel free to contact me -Yuvia.

Email: yuvia(at)hdpetgm.com

Phone/whatsapp : +86 15165330183

Click "Chat now"/"Send inquiry" to contact supplier,We will contact you within 3 minutes.

Hot Searches