It is a Mixer which can mix all the raw materials (powder form) with water and liquid chemical additives.

Capacity: 20-30kgs per batch

main motor :3kw/4kw/7.5kw

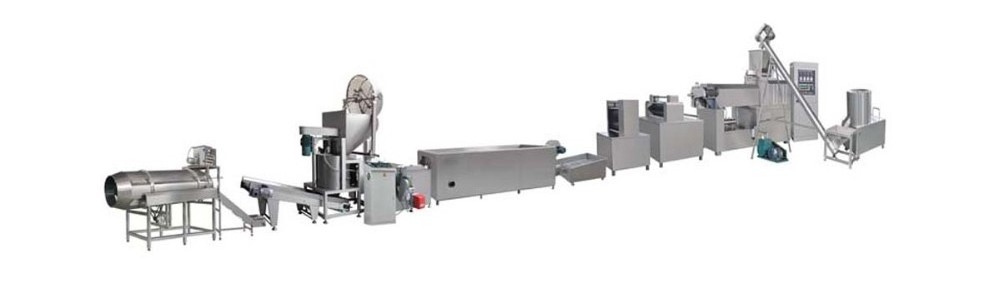

the information of Frying Snacks pellet making Extruder machine / 3D snack production line

This Big capacity pellet food processing line Is the newly designed for pellet food products both 2D and 3D shapes. The raw materials are also wheat flour, potato starch, potato flour, corn satrch, cassava starch, etc. This pellet extruder in big capacity is combined together two processes, one is pre-cooking the materials, and the other is extruding. With platform on the middle and safety guard on the top, it is easy to operate and observe during working. Such extruder structure can make bigger capacity than the usual extruder, and also can deal with all kinds of raw materials for pellet food. Its multi-functional feature makes it more and more popular to those customers who want bigger capacity.

Flow chart

Flour Mixer → Vinci Extruder → Pulling Conveyor → Pattern Machine → Compound Shaper → Elevator → Dryer →Automatic Fryer → Flavoring Line

Technical Parameter

|

Model

|

Installed Power

|

real power

|

Output

|

Dimension(mm)

|

|

DSE100 3D Pellet machine

|

172kw

|

120kw

|

80-100kg/h

|

27000x2000x2000

|

|

DSE75 3D Pellet machine

|

164kw

|

164kw

|

250-300kg/h

|

36000x2000x2000mm

|

|

DSE95 3D Pellet machine

|

394kw

|

394kw

|

400-600kg/h

|

43000x2000x3200mm

|

Raw materials : potato starch, potato flour, corn starch, corn powder, wheat flour, cassava starch etc as main materials

It is a Mixer which can mix all the raw materials (powder form) with water and liquid chemical additives.

Capacity: 20-30kgs per batch

main motor :3kw/4kw/7.5kw

The Single-screw extruder is made of the feeding system, extruding system, cutting system, heating system and controlling system.

main motor: 30kw

Some longer shape of the 3D snack will need the cutter to cut the 3D snack into pieces with different shape

main motor: 1.5kw

Continuous fryer has heat prevention layer, in order to keep temperature of oil in same temperature, meanwhile, it also prevent heat loss, increase the heat energy utilization

Continuous Fryer is matched with advanced oil filtering system to keep the oil clean all the time

main motor:45kw/68kw/86kw

It can make the food be cool avoiding sticking together and be suitable for packing. The total length of the conveyor is 5 meters. It is full set stainless steel.The height can be adjusted based on the requirement

main motor:1.5kw

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines,

how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw,

how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case (based on the customers’

need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.