<1>

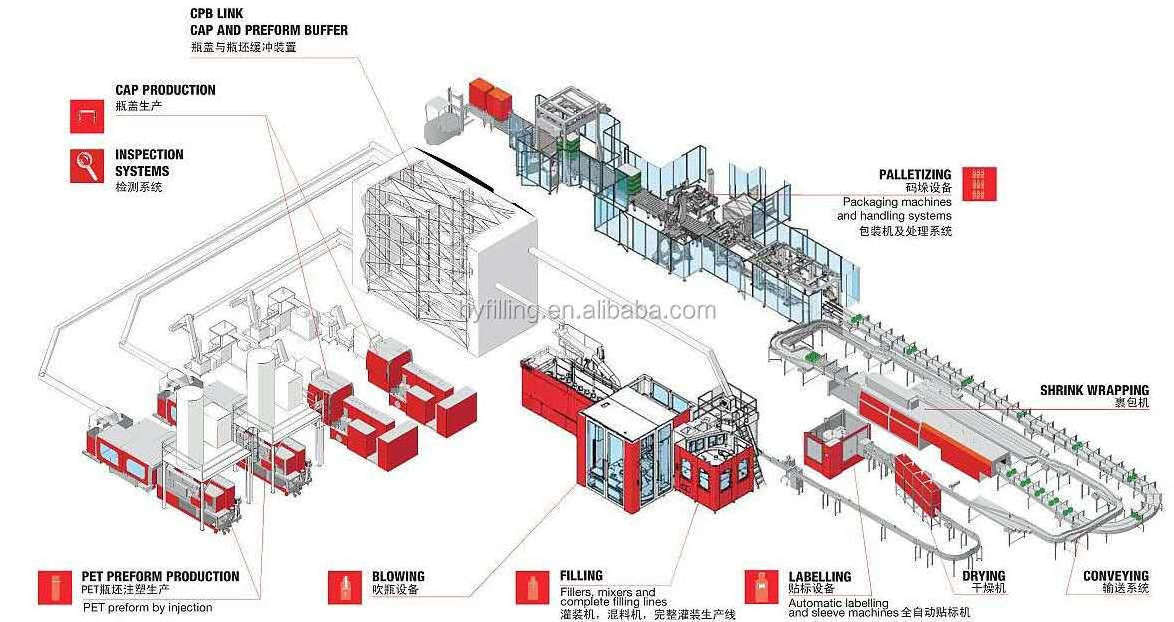

Base taking, base feeding, bottle taking and bottle arranging fully are automatically completed with manipulator for avoiding middle pollution.

<2>

The design of the recycling unit prevents the preform from getting bound up in the unscrambler.

<3>

Water cooling plate: cooling bottle neck is to avoid neck deformation during heating.