Rich oxygen membrane gas separation module for boosting combustion

-

Transport Package:

-

Standard export packaging

-

Specification:

-

60cm*60cm*225cm

-

Trademark:

-

KELIN AIER

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Hangzhou China

-

Usage:

-

Nitrogen Oxygen

-

Purpose:

-

Gas Manufacturing Gas separation Gas Purification

-

Parts:

-

Filters Air Purification Components Other

-

Application Fields:

-

Chemical Petroleum Medical Pharmaceutical Electronic New Energy Other

-

Noise Level:

-

Low

-

Machine Size:

-

Medium

-

Condition:

-

New

-

Certification:

-

ISO CE CCC Other

-

Payment:

-

L/C T/T

-

Export Port:

-

SHANGHAI NINGBO

-

Output:

-

1000pieces/year

-

Model NO:

-

MNO-1070N

Quick Details

Product overview

Rich oxygen membrane gas separation module for boosting combustion

The nitrogen generator is connected to compressed air and undergoes three-stage filtration, Clean air after removing liquid water, particulate matter, and oil moisture The electric heater is heated to 45 ℃ and enters the nitrogen magic separation process, Obtain 95~99% high-purity nitrogen gas. The system is controlled by PLC for easy operation.panel display: parameters such as flow rate, purity, temperature, etc.

Replacing bottled nitrogen or liquid nitrogen, reducing production costs, improving cutting quality and efficiency.

The nitrogen generator inside with nitrogen membrane pipe, three filters, PLC system and gas analysis, good matching for 16bar air compressor line connection to laser cutting line.

Features at a glance

|  |

Component

|  |  |

| Side photo | Front and right side photo | Inside photo |

KL-AIR nitrogen membrane module:KL NOM nitrogen generator could matching for 16bar air compressor , after the pressure drop, the out pressure could perfect get 13~15bar. N2 gas out pure 97~99% is also perfect meet the laser cutting line for metal materials cutting. About 100W power consume is also saving the cost for factory. |  |

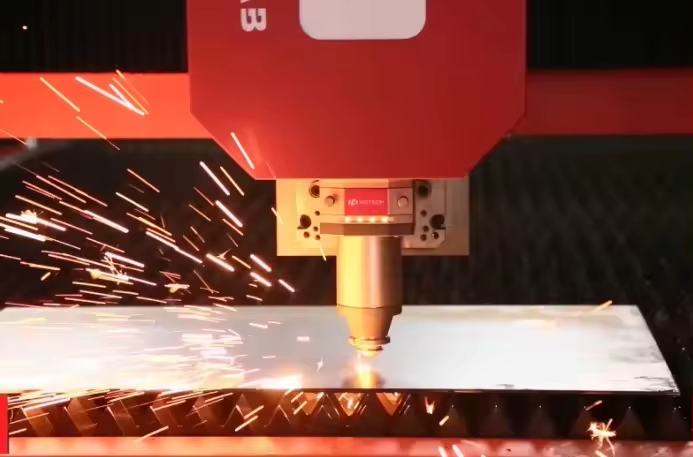

Laser cutting line----Metal cutting:

The laser cutting machine need the nitrogen gas for the protection, use the N2 gas could get the bright & smooth cutting surface.

liquid nitrogen is expensive. and factory need pay attention for safety use & stock. Usually, the cutting line they donot need high pure liquied nitrogen. 97~99% is perfect. but the puressure is need 12~14bar.

PSA gas generator out pressure is 6~8bar, if use the PSA system, user need add a gas compressor for their laser cutting line.

Specification table

No | Pure % | Flow rate Nm3/h | Pressure Bar | Dew point Deg.C | Power |

1 | 99 | 23 | 13~16 | -20 | 2.2 |

2 | 98 | 33 | 13~16 | -20 | 2.2 |

3 | 97 | 44 | 13~16 | -20 | 2.2 |

4 | 96 | 54 | 13~16 | -20 | 2.2 |

5 | 95 | 65 | 13~16 | -20 | 2.2 |

Product Configuration

PLC controller & touch screen |  Nitrogen membrane pipe |  Compressed air filter |

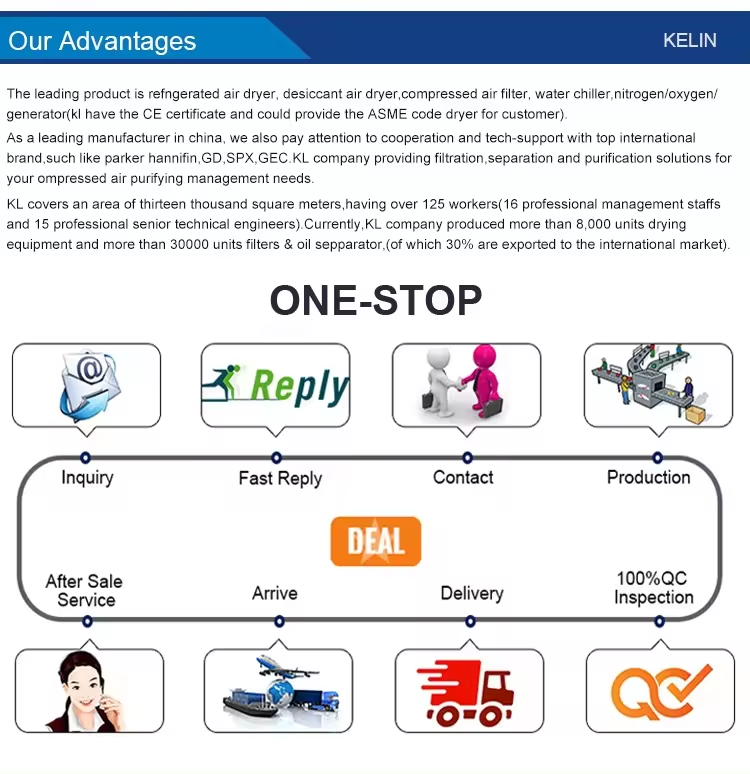

Company profile

Exhibition

Packaging&shiping

FAQ

1. Are you manufacturer or Trade Company?

We are OEM professional air dryer, founded in 1997.

Leading products: compressed air dryer, desiccant air dryer, air filter, water chiller, PSA gas generator.

2. What terms of payment you use?

T/T, L/C

3. Do you have any instant chat tool?

Any Inquiry or question, pls contact:

Hangzhou Kelin Aier Qiyuan Equipment Co.ltd

Main Product: air dryer & water chiller & gas generator etc.

Add:Anxi Industrial Zone,Liangzhu,Yuhang,Hangzhou,China