- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

150bag/min

-

Weight (KG):

-

287

-

Voltage:

-

380V

-

Place of Origin:

-

Henan

-

Brand Name:

-

WKS

-

Dimension(L*W*H):

-

2880*1300*1400

-

Product name:

-

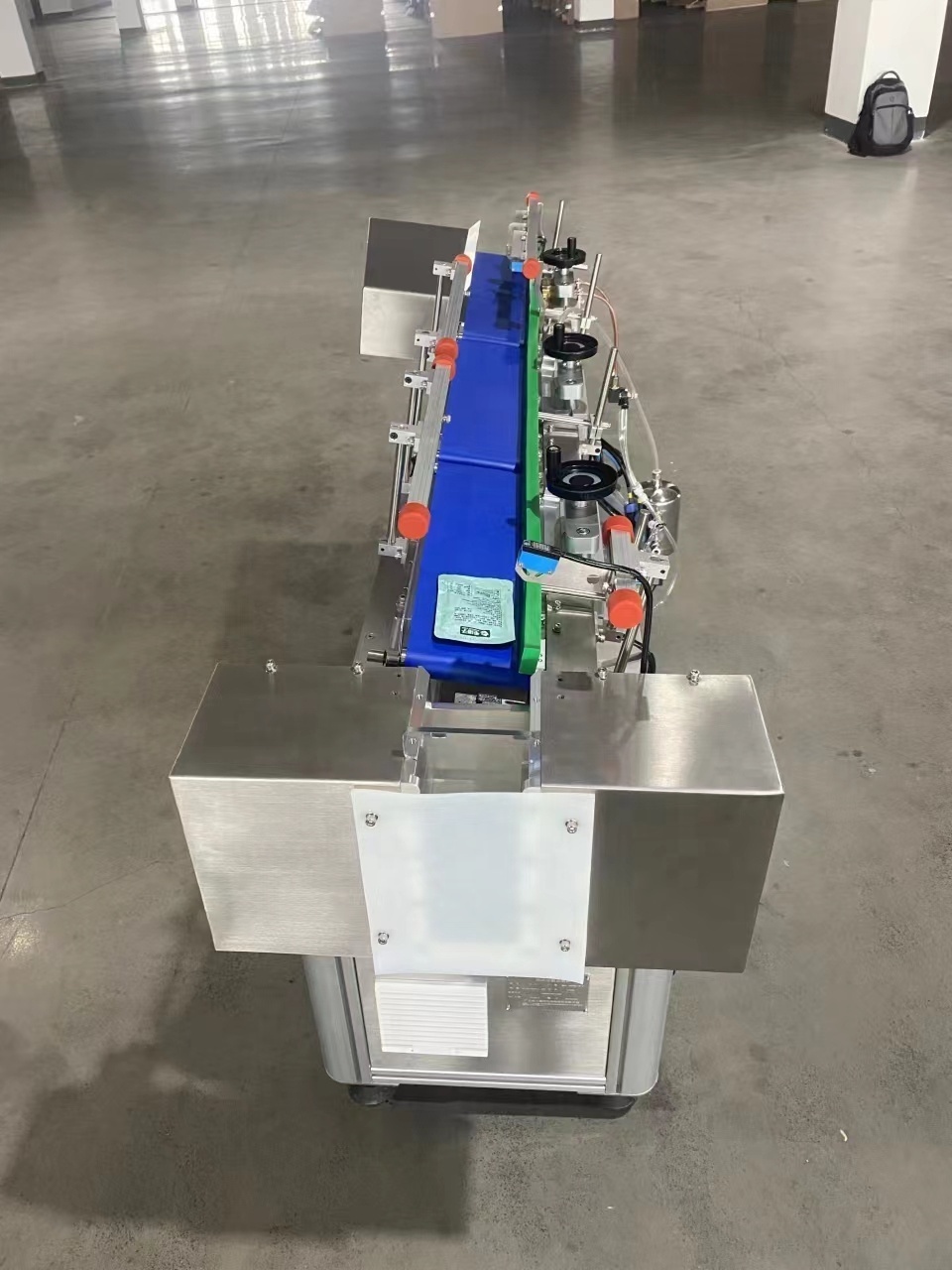

Bag sorting machine

-

Usage:

-

Food Snack

-

Main Function:

-

Automatic Form

-

After-sales Service Provided:

-

Online Support

-

Suitable for:

-

High Viscous Products

-

Keyword:

-

High Speed

-

Packing speed:

-

40-230 Bags/min

-

Advantage:

-

Easy Operation High Efficiency

-

Feature:

-

Multi-purpose Packing Machine

Quick Details

-

Function:

-

counting

-

Packaging Type:

-

Cartons, Bags, Belt

-

Packaging Material:

-

Plastic, Paper

-

Production Capacity:

-

150bag/min

-

Weight (KG):

-

287

-

Voltage:

-

380V

-

Place of Origin:

-

Henan

-

Brand Name:

-

WKS

-

Dimension(L*W*H):

-

2880*1300*1400

-

Product name:

-

Bag sorting machine

-

Usage:

-

Food Snack

-

Main Function:

-

Automatic Form

-

After-sales Service Provided:

-

Online Support

-

Suitable for:

-

High Viscous Products

-

Keyword:

-

High Speed

-

Packing speed:

-

40-230 Bags/min

-

Advantage:

-

Easy Operation High Efficiency

-

Feature:

-

Multi-purpose Packing Machine

Video Description

Product Overview

Introduction

The automatic bag sorting machine can be used alone in production, or can be connected with the cartoning machine to complete the entire process of sorting irregularly accumulated materials from concentration to dispersion to sequential placement. After the irregularly accumulated materials are poured into the storage silo, the conveyor belt of the silo moves to transport the materials to the low-speed rollers. The equipment sends the materials out of the bag sorting machine one by one through the operation of low, medium and high-speed rollers. The delivered materials are transported by the cartoning machine according to the form or order required for packaging or stacked to complete the next step of the cartoning process.

Performance characteristics

● Integrated design of storage, loading and bag sorting, simple structure, compact and elegant appearance;

● Overall sealing, safe operation.

● Integrated large-capacity storage bin for easy feeding.

● The bottom of the silo is equipped with a conveyor belt to facilitate material loading and avoid material residue.

● The material distribution and conveying roller is driven by 10 sets of servo motors, and the speed is adjusted through the feedback signal of the photoelectric sensor. The control is precise and the bag sorting speed is fast.

● Fully automatic arrangement is realized through servo control. The multi-servo system realizes regular and orderly stacking of materials, making the process stable and controllable.

● The entire process is decentralized, sequential, and stacked without manual intervention.

● Multiple method combinations, the number of bag sorting machines can be increased or decreased according to speed needs, and a single machine can also complete the sorting process.

●Multi-servo system control, high speed and precision, easy operation and high degree of automation

Application

Parameters

|

Servo quantity

|

10 set

|

|

Speed

|

Stable speed 130-180 packages/min (the speed is related to the actual incoming materials); production efficiency is adjustable

|

|

Material size

|

25*130mm or 25*133mm

|

|

Applicable product size

|

Length 60-200mm; Width 30-150mm

|

|

Roller diameter

|

φ18mm

|

|

Whole machine size

|

2880*1300*1400mm(Matching hopper)

|

|

Machine material

|

2mm thick SUS304;4mm thick carbon steel bracket

|

|

Power

|

4.7kw

|

|

Weight

|

287kg

|

|

Voltage

|

380V/50hz;3 phase

|

Product details

Smart touch screen

Visual operation

Conveying; sorting; feeding; packaging fully automated

Multi-level frequency conversion

Servo drive control

Hot Searches