- Product Details

- {{item.text}}

Quick Details

-

Drilling Speed:

-

Normal Speed

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIUCHENG

-

Model Number:

-

Z3040*14/1

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2053X820X2483 mm

-

Power (kW):

-

1.5/2.2kw

-

Weight (KG):

-

2400 KG

-

Spindle Travel(mm):

-

300mm

-

Application:

-

Metal Processing

-

Max. drilling Dia:

-

50MM

-

Name:

-

China Radial Drilling Machine

-

Type:

-

Radial Drilling Mahine

-

Color:

-

Customizable

-

Machine type:

-

Drilling Equipment

-

Precision:

-

0.3mm

-

Product name:

-

Radial Drilling Machine

-

Power(W):

-

2.2

Quick Details

-

type:

-

Radial Drilling Machine

-

Max. Drilling Dia. (mm):

-

40 mm

-

Range of Spindle Speed(r.p.m):

-

25 - 2000 r.p.m

-

Drilling Speed:

-

Normal Speed

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JIUCHENG

-

Model Number:

-

Z3040*14/1

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2053X820X2483 mm

-

Power (kW):

-

1.5/2.2kw

-

Weight (KG):

-

2400 KG

-

Spindle Travel(mm):

-

300mm

-

Application:

-

Metal Processing

-

Max. drilling Dia:

-

50MM

-

Name:

-

China Radial Drilling Machine

-

Type:

-

Radial Drilling Mahine

-

Color:

-

Customizable

-

Machine type:

-

Drilling Equipment

-

Precision:

-

0.3mm

-

Product name:

-

Radial Drilling Machine

-

Power(W):

-

2.2

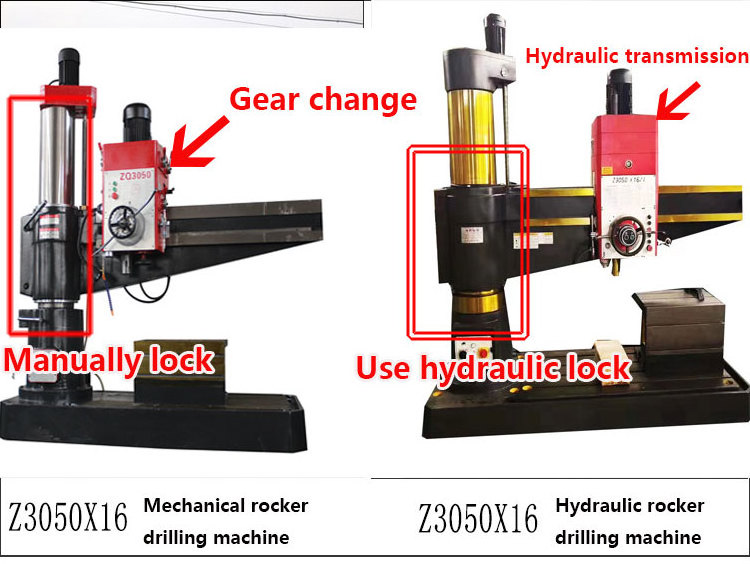

Features:

L. Subdivy changes

Through the triad sliding gear on the Ⅱ axis and the two -united sliding gear on the axis of the axis, different gears on the axis

Wad, so that the main axis gets 6 different speeds.

2. Advanced changes

Three pairs of gears to decelerate the gear on the main axis , and then through the triple slip on the axis of the axis

The meshing of different gears on the shift gear and the axis, and the main axis is obtained without the speed of the level 3.

3. Advanced transmission insurance institutions

There is a steel ball insurance clutch between the axis and the worm shaft. When the spindle feeds exceed the specified value,

Steel ball clutch slipped.

4. From the feed transmission shaft , the clutch clutch, the worm, the worm wheel, the steel ball binder, the horizontal gear shaft, and the main axis of the spindle are passed to the main axis. The combination of the combination of the child can achieve manual admission.

Give.

5. Subdivy balance

Using a section spring type, both ends of the strip are fixed on the spring box and the transmission shaft, respectively, and fixing one teeth at the axis end

The wheel and the horizontal axis gear mesh. When the spindle is moved up or down, due to the turn of the horizontal axis, the clockwork follow

Rotate and make the spindle always balanced.

6. Clamp the main axis box

By clamping the handle, eccentric axis, top -selling, and pressing blocks, the main shaft box is clamped with the horizontal arm guide.

7. Horizontal lifting

The motor is achieved by two pairs of gears and screws, and silk mother. One group of gears are equipped with steel ball insurance device, and the insurance torque is about 10-12 Nm, which is adjusted by the nut on the middle shaft.

8. Clamping

Through clamping the handle and bolt nut to eliminate the gap between the rocker and the columns, the clamping

The large weight and stiff construction of the drill ensures stability and vibration free operation

Height adjustment of the arm by motor

Control panel located on the front of the drill for better performance and ergonomics

The polished surface of the column ensures easy, free and precise travel of the arm

Drill equipped with manual blocking of the head and arm of the column

The large speed range ensures precise and fast processing

|

Model

|

Unit

|

ZQ3040×10

|

ZQ3040×13

|

|

Max.drilling capacity

|

mm

|

40

|

40

|

|

Distance spindle axis to column generating line

|

mm

|

360-1000

|

360-1100

|

|

Diameter of column

|

mm

|

230

|

230

|

|

Spindle taper

|

MT4

|

MT4

|

|

|

Spindle travel

|

mm

|

200

|

200

|

|

Spindle speed range

|

r/min

|

75-1200

|

75-1200

|

|

Spindle speed number

|

6

|

6

|

|

|

Range of Spindle feed

|

mm/r

|

0.10-0.25

|

0.10-0.25

|

|

Spindle feed number

|

3

|

3

|

|

|

Distance spindle nose to working surface of base

|

mm

|

260-1050

|

260-1050

|

|

Dimension of worktable

|

mm

|

400×450×400

|

400×450×400

|

|

Overall size

|

mm

|

1500×705×2200

|

1500×705×2250

|

|

Power of Main motor

|

KW

|

2.2

|

2.2

|

|

Machine weight

|

Kg

|

1200

|

1300

|

|

Packing dimension

|

mm

|

1870×970×2200

|

2350×1060×2450

|