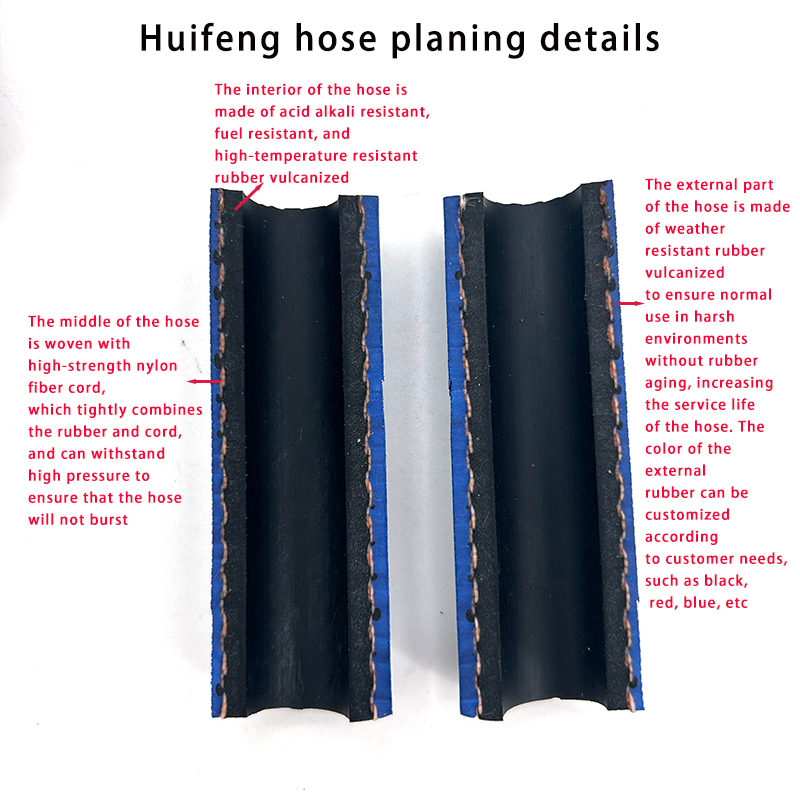

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

001

-

Product name:

-

High pressure cleaning machine hose

-

Material:

-

High Tensile Steel Wire/Rubber

-

Application:

-

Car cleaning, ship cleaning

-

Color:

-

Customized Color

-

Feature:

-

Black, color customization

-

Type:

-

Rubber Soft Tube

-

Usage:

-

Car cleaning, ship cleaning

-

Quality:

-

Bad one pays three

-

Characteristics:

-

Weather-Aging Resistance

-

Delivery Time:

-

7-15 Days

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HUIFENG

-

Model Number:

-

001

-

Product name:

-

High pressure cleaning machine hose

-

Material:

-

High Tensile Steel Wire/Rubber

-

Application:

-

Car cleaning, ship cleaning

-

Color:

-

Customized Color

-

Feature:

-

Black, color customization

-

Type:

-

Rubber Soft Tube

-

Usage:

-

Car cleaning, ship cleaning

-

Quality:

-

Bad one pays three

-

Characteristics:

-

Weather-Aging Resistance

-

Delivery Time:

-

7-15 Days

You may also like

TOP rubber hose manufacturer, specializing in the production of silicone hoses, rubber hoses, fuel hoses, etc. Wholesale factory prices, complete models and specifications, quality assurance, to meet all your customized needs. If you are interested in our products,

Please contact me to obtain a quotation and free samples

Products Show

Huifeng Rubber & Plastic provides you with a wide range of hydraulic hoses and accessories

for a variety of applications in many industries.

Our hydraulic hose series includes 1SC, 2SC, 100 R1-R17, 4SP, 4SH, 1SN, 2SN, 1-3TE and suction and delivery hoses, as well as

compatible hose inserts and ferrule.

If you are not sure which type of hose should be used in your application, please contact us and we will provide you with the

correct hose!

We not only provide bulk hoses and hose fittings, we can also customize hose assemblies according to your given specifications,

please contact our friendly sales team immediately to discuss your hose assembly needs.

for a variety of applications in many industries.

Our hydraulic hose series includes 1SC, 2SC, 100 R1-R17, 4SP, 4SH, 1SN, 2SN, 1-3TE and suction and delivery hoses, as well as

compatible hose inserts and ferrule.

If you are not sure which type of hose should be used in your application, please contact us and we will provide you with the

correct hose!

We not only provide bulk hoses and hose fittings, we can also customize hose assemblies according to your given specifications,

please contact our friendly sales team immediately to discuss your hose assembly needs.

SAE 100 R2 steel wire reinforced hydraulic hose is suitable for delivering petroleum-based

hydraulic oils thanks to its oil resistant tube. Besides, it can convey the oils without producing excessive heat and leak. It is

mainly used in some mobile equipment, such as farm tractor, dump truck and in-plant hydraulic equipment. It is composed of three

parts: tube, reinforcement and cover. The tube is made from oil resistant synthetic rubber, so it is mainly used to transfer oils.

The reinforcement is made from two layers of high tensile braided steel wires, making the hose have solid structure and resistant

to high pressure. Therefore, it has excellent performance in high pressure working environment.

hydraulic oils thanks to its oil resistant tube. Besides, it can convey the oils without producing excessive heat and leak. It is

mainly used in some mobile equipment, such as farm tractor, dump truck and in-plant hydraulic equipment. It is composed of three

parts: tube, reinforcement and cover. The tube is made from oil resistant synthetic rubber, so it is mainly used to transfer oils.

The reinforcement is made from two layers of high tensile braided steel wires, making the hose have solid structure and resistant

to high pressure. Therefore, it has excellent performance in high pressure working environment.

SAE 100 R2 steel wire reinforced hydraulic hose:

Structure: it is composed of three parts: tube, reinforcement and cover.

Tube: high quality synthetic rubber, making the hose resistant to abrasion, corrosion and oils.

Reinforcement: two layers of high tensile braided steel wires, making the hose have excellent performance in high pressure working

conditions.

Cover: high quality synthetic rubber, making the hose resistant to abrasion, corrosion, cut, aging, weather and ozone.

Working temperature: -40 °C to +100 °C.

Structure: it is composed of three parts: tube, reinforcement and cover.

Tube: high quality synthetic rubber, making the hose resistant to abrasion, corrosion and oils.

Reinforcement: two layers of high tensile braided steel wires, making the hose have excellent performance in high pressure working

conditions.

Cover: high quality synthetic rubber, making the hose resistant to abrasion, corrosion, cut, aging, weather and ozone.

Working temperature: -40 °C to +100 °C.

|

I.D

|

|

W.D

|

|

O.D

|

|

W.P

|

P.P

|

B.P

|

Min B.R

|

|||

|

mm

|

Inch

|

Min

|

Max

|

Min

|

Max

|

Mpa

|

Mpa

|

Mpa

|

mm

|

|||

|

5

|

3/16

|

9

|

10

|

11.1

|

13

|

25

|

50

|

100

|

85

|

|||

|

6.3

|

1/4

|

10.6

|

11.6

|

12.7

|

14

|

22.5

|

45

|

90

|

100

|

|||

|

8

|

5/16

|

12.1

|

13.3

|

14.3

|

16

|

21.5

|

43

|

86

|

115

|

|||

|

10

|

3/8

|

14.5

|

15.7

|

16.7

|

18

|

18

|

36

|

72

|

130

|

|||

|

12.5

|

1/2

|

17.5

|

19.1

|

19.8

|

21

|

16

|

32

|

64

|

180

|

|||

|

16

|

5/8

|

20.6

|

22.2

|

22.9

|

25

|

13

|

26

|

52

|

200

|

|||

|

19

|

3/4

|

24.6

|

26.2

|

26.9

|

29

|

10.5

|

21

|

42

|

240

|

|||

|

25

|

1

|

32.5

|

34.1

|

34.6

|

37

|

8.8

|

17.6

|

35.2

|

300

|

|||

|

31.5

|

1--1/4

|

39.3

|

41.7

|

42.2

|

45

|

6.3

|

12.6

|

25.2

|

420

|

|||

|

38

|

1-1/2

|

45.6

|

48

|

49.1

|

52

|

5

|

10

|

20

|

500

|

|||

|

51

|

2

|

58.7

|

61.7

|

62.5

|

66

|

4

|

8

|

16

|

630

|

|||

|

I.D

|

|

W.D

|

|

O.D

|

|

W.P

|

P.P

|

B.P

|

Min B.R

|

|||

|

mm

|

Inch

|

Min

|

Max

|

Min

|

Max

|

Mpa

|

Mpa

|

Mpa

|

mm

|

|||

|

5

|

3/16

|

10.6

|

11.6

|

12.7

|

14

|

41.5

|

83

|

166

|

90

|

|||

|

6.3

|

1/4

|

12.1

|

13.3

|

14.3

|

16

|

40

|

80

|

160

|

100

|

|||

|

8

|

5/16

|

13.7

|

14.9

|

15.9

|

17

|

35

|

70

|

140

|

115

|

|||

|

10

|

3/8

|

16.1

|

17.3

|

18.3

|

20

|

33

|

66

|

132

|

130

|

|||

|

12.5

|

1/2

|

19

|

20.6

|

21.4

|

23

|

27.5

|

55

|

110

|

180

|

|||

|

16

|

5/8

|

22.2

|

23.8

|

24.6

|

26

|

25

|

50

|

100

|

200

|

|||

|

19

|

3/4

|

26.2

|

27.8

|

28.5

|

30

|

21.5

|

43

|

86

|

240

|

|||

|

25

|

1

|

34.1

|

35.7

|

37.3

|

39

|

16.5

|

33

|

66

|

300

|

|||

|

31.5

|

1-1/4

|

43.3

|

45.7

|

47.1

|

50

|

12.5

|

25

|

50

|

420

|

|||

|

38

|

1-1/2

|

49.6

|

52

|

53.3

|

56

|

9

|

18

|

36

|

500

|

|||

|

31

|

2

|

62.3

|

64.7

|

66

|

69

|

8

|

16

|

32

|

630

|

|||

|

I.D

|

|

W.D

|

|

O.D

|

|

W.P

|

P.P

|

B.P

|

Min B.R

|

|||

|

mm

|

Inch

|

Min

|

Max

|

Min

|

Max

|

Mpa

|

Mpa

|

Mpa

|

mm

|

|||

|

10

|

3/8

|

16.9

|

18.1

|

20.6

|

22.2

|

44.5

|

89

|

178

|

180

|

|||

|

12.5

|

1/2

|

19.4

|

21

|

23.8

|

25.4

|

41.5

|

83

|

166

|

230

|

|||

|

16

|

5/8

|

23

|

24.6

|

27.4

|

29

|

35

|

70

|

140

|

250

|

|||

|

19

|

3/4

|

27.4

|

29

|

31.4

|

33

|

28

|

70

|

140

|

300

|

|||

|

25

|

1

|

34.5

|

36.1

|

38.5

|

40.9

|

21

|

56

|

112

|

340

|

|||

|

31.5

|

1-1/4

|

45

|

47

|

49.2

|

52.4

|

18.5

|

42

|

84

|

460

|

|||

|

38

|

1-1/2

|

51.4

|

53.4

|

55.6

|

58.8

|

16.5

|

37

|

74

|

560

|

|||

|

51

|

2

|

64.3

|

66.3

|

68.2

|

71.4

|

35

|

33

|

66

|

660

|

|||

|

64

|

2-1/2

|

76

|

78

|

83.1

|

85.5

|

35

|

70

|

140

|

990

|

|||

|

76

|

3

|

100

|

103

|

105.1

|

108

|

35

|

70

|

140

|

1200

|

|||

|

89

|

3-1/2

|

114

|

115.5

|

118

|

122

|

35

|

70

|

140

|

1300

|

|||

|

102

|

4

|

126

|

128

|

131

|

134.2

|

35

|

70

|

140

|

1400

|

|||

|

I.D

|

|

W.D

|

|

O.D

|

|

W.P

|

P.P

|

B.P

|

Min B.R

|

|||

|

mm

|

Inch

|

Min

|

Max

|

Min

|

Max

|

Mpa

|

Mpa

|

Mpa

|

mm

|

|||

|

19

|

3/4

|

27.6

|

29.2

|

31.4

|

33

|

42

|

84

|

168

|

280

|

|||

|

25

|

1

|

34.4

|

36

|

37.5

|

39.9

|

38

|

76

|

152

|

340

|

|||

|

31.5

|

1-1/4

|

40.9

|

42.9

|

43.9

|

47.1

|

32.5

|

65

|

130

|

460

|

|||

|

38

|

1-1/2

|

47.8

|

49.8

|

51.9

|

55.1

|

29

|

58

|

116

|

560

|

|||

|

51

|

2

|

62.2

|

64.2

|

66.5

|

69.7

|

25

|

50

|

100

|

700

|

|||

Packing & Delivery

Hot Searches