1.We feature an experienced engineering team with ISO 9001:2015 quality system that is adaptable enough to cater for one-off

prototypes through to production in volume. Our dedicated “Planning and Estimating Team” can evaluate and price all your requirements in a timely fashion.

2.All in the company's customized mold product production quantity reaches 800 thousand,return the mold fee,reach the life can be free to re-open mold

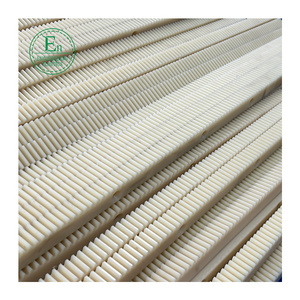

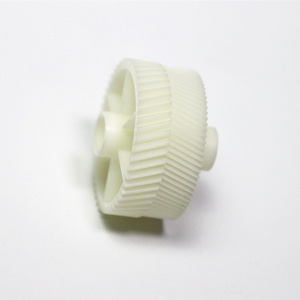

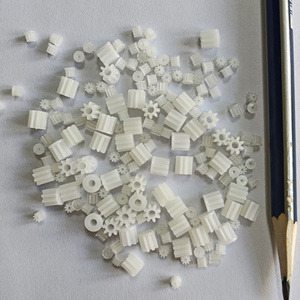

3.Wholesale of standard and nonstandard high-precision plastic gears, plastic pulleys and plastic gearboxes

4.Designing, processing and manufacturing high-precision plastic gears and parts according to your drawings or samples

5.Precision plastic injection molding and tooling

- Product Details

- {{item.text}}

Quick Details

-

Processing:

-

Grinding

-

Application:

-

Transmission Gearbox

-

Size:

-

customized

-

Certificate:

-

ISO9001

-

Quality:

-

good

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

0.1

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ADX

-

Processing:

-

Grinding

-

Application:

-

Transmission Gearbox

-

Size:

-

customized

-

Certificate:

-

ISO9001

-

Quality:

-

good

-

After Warranty Service:

-

Video technical support

Product Description

|

Product Features

|

|

|

|

*Brand

|

ADX

|

|

|

*Product name

|

Plastic Gears

|

|

|

*Color

|

Customize

|

|

|

*Material

|

POM, PEEK, ABS, Nylon, PVC, etc

|

|

|

*Lead Time

|

1-2 weeks for samples, 3-4 weeks for mass production

|

|

|

*Quality Assurance

|

ISO9001:2015

|

|

|

*Drawing Accepted

|

Solid Works, Pro/Engineer, Auto CAD(DXF, DWG), PDF

|

|

|

*Processing

|

CNC turning, CNC milling, CNC turn-milled, Laser cutting

|

|

Manufacturing Shop

QC Flow Chart

Related Products

Company Introduction

Huizhou AiDiXing Intelligent Technology Industrial Co., Ltd. is a professional manufacturer of engineering plastic products.Mold development, design, processing, production, sales, as one of the comprehensive system.The company has a full set of imported production equipment, a full set of advanced CNC machine tools, injection molding machine.Rich manufacturing experience and technology.

Why Choose Us

Certifications and Our Advantages

Cooperative Partner

FAQ

1.Are you a manufacturer or a trading company?

We are a 3000-square-meter factory located in HuiZhou of GuangDong Province, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and process requirement information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

We are a 3000-square-meter factory located in HuiZhou of GuangDong Province, China.

2.How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and process requirement information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

4.Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Hot Searches