- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Brand Name:

-

wadley

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

5800*900*1500

-

Weight:

-

1500 kg

-

Feeding width:

-

114

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

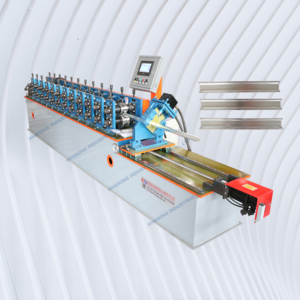

Omega Furring Roll Forming Machine

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Main frame:

-

300/350mm H-Beam

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Profiles:

-

OMEGA Metal Roof Forming Machine

-

Plc:

-

DETLA

-

Keywords:

-

Omega Roll Forming Machine

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

China

-

Brand Name:

-

wadley

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

5800*900*1500

-

Weight:

-

1500 kg

-

Feeding width:

-

114

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Omega Furring Roll Forming Machine

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr12Mov Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Main frame:

-

300/350mm H-Beam

-

Raw material:

-

PPGI PPGL GI GL

-

Cutting type:

-

Automatic Hydraulic Cutting

-

Profiles:

-

OMEGA Metal Roof Forming Machine

-

Plc:

-

DETLA

-

Keywords:

-

Omega Roll Forming Machine

Product Description

Omega Profile Light Gauge Steel Framing Cold Roll Forming Machine :

Light gauge roll forming machine, the light steel keel is made of high-quality continuous hot-dip galvanized sheet and strip as raw materials, and is rolled into a metal frame for construction through a cold bending process. It is suitable for the decoration of the roof of various buildings, the inner and outer walls of the building and the scaffold The base material of the suspended ceiling. The light steel keel includes ceiling keel and partition keel according to the purpose, and V-shaped, C-shaped, T-shaped, L-shaped and U-shaped keels according to the cross-sectional form.This wall stud roll forming machine produces multi-profiles and size-changing by the spacer. In fact, it is multi size wall stud and tracks machine for multi-profiles,size-changing by the spacer.There is an enlarged hydraulic station to ensure high-speed working. Easy operation, low maintenance cost.

We are online 24 hours a day , and welcome friends from all over the world to Inquiry( https://wdlstore.en.alibaba.com/contactinfo.html ) at any time to obtain more discounts.

We are online 24 hours a day , and welcome friends from all over the world to Inquiry( https://wdlstore.en.alibaba.com/contactinfo.html ) at any time to obtain more discounts.

Assembly line process flow:

3T

Manual feeding rack- -Guiding device - Roll forming systerm - Cutting device - Run out tabla for product

Specification

|

item

|

value

|

|

Voltage

|

380V/220V/415V

|

|

Rolling thinckness

|

0.3-1mm

|

|

Feeding width

|

114

|

|

Product name

|

5800*900*1500

|

|

Roller material

|

45# Forged Steel

|

|

Cutting blade material

|

Cr12Mov Steel

|

|

Shaft material

|

45# Steel Outer Diameter: 70mm

|

|

Main frame

|

300/350mm H-Beam

|

|

Raw material

|

PPGI PPGL GI GL

|

|

Cutting type

|

Automatic Hydraulic Cutting

|

|

Plc

|

DETLA

|

|

Keywords

|

Omega Roll Forming Machine

|

|

Dimension(L*W*H)

|

5800*900*1500

|

|

Weight

|

1500kg

|

Machine Parts Detail

Customers who enter the store and send inquiry and place orders within two weeks will all receive this material receiving rack as a gift

♥

!

WHY CHOOSE US:

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our Technical Personnel Provide On-Site Services Overseas:

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1.Standard export wooden box packaging or 20ft or 40ft container;

2.Fit for ocean shipping;

3.The main body of the roll forming machine will be naked packing into the container,covered with plastic film.

4.Steel wire fix the machine into the container, in case any damage when shaking on the sea.

5.The spare parts will be packed into the carton box.

6.The received goods table put into carton box .

7.Manual decoiler naked package.

Safe arrival at our client's site:

Hot Searches