- Product Details

- {{item.text}}

Quick Details

-

Size:

-

1450mm*1450mm*800mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haijie

-

Power:

-

4KW

-

Product name:

-

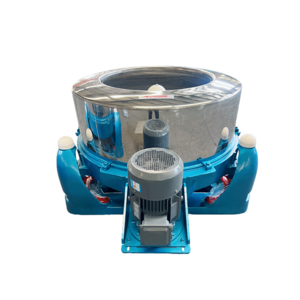

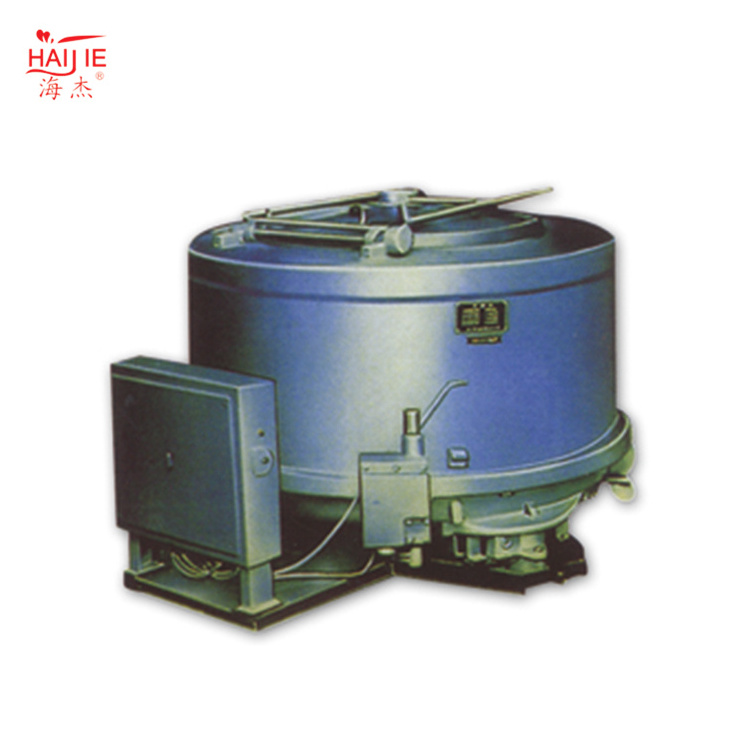

commercial hydro extractor

-

Material:

-

Stainless steel

-

Keywords:

-

Industrial dewatering machine

-

Application:

-

Clothes ,food ,chemical raw materials,latex products

-

Feature:

-

Large capacity ,variable frequency,quakeproof

-

Industry Used:

-

Hotel ,hospital ,school,laundry,etc

-

Function:

-

Dewatering,separation,filtration

-

MOQ:

-

1set

-

Max.capacity:

-

25/45/80/130/220/500kg

Quick Details

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Video technical support, Online support

-

Weight:

-

760KG

-

Size:

-

1450mm*1450mm*800mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haijie

-

Power:

-

4KW

-

Product name:

-

commercial hydro extractor

-

Material:

-

Stainless steel

-

Keywords:

-

Industrial dewatering machine

-

Application:

-

Clothes ,food ,chemical raw materials,latex products

-

Feature:

-

Large capacity ,variable frequency,quakeproof

-

Industry Used:

-

Hotel ,hospital ,school,laundry,etc

-

Function:

-

Dewatering,separation,filtration

-

MOQ:

-

1set

-

Max.capacity:

-

25/45/80/130/220/500kg

Pollution prevention stable mobile roller dewatering machine

| Model |

1. Lower blowdown dewatering machine

2. Upper discharge dewatering machine 3. Fixed centrifugal dewatering machine 4. Mobile dewatering machine |

| Daily maintenance |

1: The operator must be familiar with the structure, performance and operation of the machine.

2: Turn the number of turns before turning on the machine to check the running status of the switch. 3: The feeding should be evenly distributed to avoid excessive vibration caused by excessively large machine vibration. 4: Do not brake the opening and closing arm during normal operation to avoid damage to the belt and other parts. 5: No items can be placed on the top cover to avoid accidents after starting the machine. 6: If abnormal phenomena are found during operation, the power should be cut off immediately and the brakes should be stopped for inspection. 7: The machine must be inspected regularly, filled with lubricating oil, and repaired at least once every six months. |

| Precautions |

1: Put the material to be dehydrated evenly into the switch, pay attention to balance, uniformity and overload.

2: After the motor is turned on for about 90 seconds, the machine reaches normal operation, and the outlet pipe begins to discharge a large amount of water. 3: The machine runs for about 6-8 minutes. The outlet pipe is basically free from water flow, and the power can be cut off. After 1-2 minutes, the brakes are braked slowly and the machine stops. 4: Do not put materials into the machine during operation, so as to avoid the high-speed rotating drum to break the material and injure people and objects. |

| Product introduction |

1. The industrial dewatering machine is a kind of washing equipment. It is a kind of equipment that uses the centrifugal force of the inner cylinder to rotate and centrifugal force generated by high-speed rotation to remove the moisture contained in the object.

2. Industrial dewatering machine, centrifugal dewatering machine is mainly used in various spinning (needle) fabrics, garments, printing and dyeing, food, hardware, chemical raw materials, latex products enterprises and institutions. 3. Industrial application is applicable to various metal parts after grinding, cutting, oil washing, washing, cooling, dipping and anti-rust liquid dehydration (oil), suitable for small hardware, electronic parts, iron filings, aluminum filings, copper shavings Drying, dehydration, deoiling; and electroplating and grinding processing plants, metal lathe processing plants, hardware fasteners factories and other plants. |

| Characteristics |

1: The industrial dewatering machine and the centrifugal dewatering machine are all three-legged pendulum structure, which can avoid the vibration of the foot during operation due to the imbalance of the load inside the switch.

2: Industrial dewatering machine, the inner cylinder and outer casing of the centrifugal dewatering machine are made of stainless steel plate material, the switch is made of stainless steel plate, the cage base and the chassis are cast iron materials, and the outlet pipe is below the chassis. 3: Industrial dewatering machine, the centrifugal dewatering machine main shaft is made of high quality steel and heat treated. 4: Industrial dewatering machine, the transmission part of the centrifugal dewatering machine is driven by triangular tape, and the centrifugal starting wheel is directly driven by the motor, which can make the machine start slowly and gradually reach the design speed to ensure the smooth running of the machine. 5: Industrial dewatering machine, centrifugal dewatering machine has a brake opening and closing arm, which has good braking performance and can make the machine stop quickly. |

|

Model No.

|

Max.capacity ( kg ) |

Motor Power ( kw ) |

Speed of drum (r/min) |

Diameter of drum (mm) |

High of drum (mm) |

Overall dimensions(mm)

|

Machine weight ( kg ) |

|

SS752-500 |

25 |

1.5 |

960 |

500 |

300 |

1000×1000×650 |

250 |

|

SS753-600 |

45 |

2.2 |

960 |

600 |

300 |

1250×1250×700 |

450 |

|

SS752-800 |

80 |

4 |

910 |

800 |

340 |

1400×1400×800 |

760 |

|

SS751-1000 |

130 |

5.5 |

900 |

1000 |

380 |

1800×1800×900 |

1100 |

|

SS754-1200 |

220 |

7.5 |

700 |

1200 |

480 |

2000×2000×1020 |

1600 |

|

500 |

11 |

750 |

1500 |

600 |

2550×1950×1400 |

2400 |

Pollution prevention stable mobile roller dewatering machine