- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

Huarui

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot

-

Product name:

-

Roofing Sheet Making Machine

-

Roller stations:

-

13rows

-

Diameter of main shaft:

-

80mm

-

Forming Speed:

-

8-15m/minute

-

Power of main motor:

-

7.5kw

-

Motor power of pump station:

-

4kw

-

Raw material:

-

metal sheet

-

Thickness of sheet:

-

0.3-0.8mm

-

MOQ:

-

1 set

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

Huarui

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot

-

Product name:

-

Roofing Sheet Making Machine

-

Roller stations:

-

13rows

-

Diameter of main shaft:

-

80mm

-

Forming Speed:

-

8-15m/minute

-

Power of main motor:

-

7.5kw

-

Motor power of pump station:

-

4kw

-

Raw material:

-

metal sheet

-

Thickness of sheet:

-

0.3-0.8mm

-

MOQ:

-

1 set

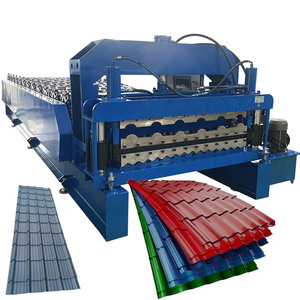

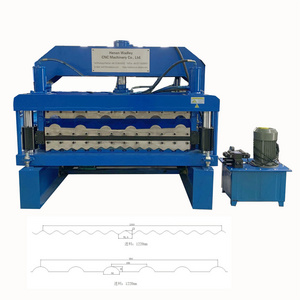

Single layer Double layer Roofing Sheet Making Roll Forming Machine

|

|

|

|

Corrugated roofing sheet, is a very popular and common roof sheet in all over the world.

Product Description

Main technical parameters:

| Main technical parameter | ||

| 1 | Decoiler | 1. Bearing: 5T |

| 2. Feeding way: Manual with brake | ||

| 3 | Main Forming System | 1. Feeding width: 1000 mm |

| 2. Roller stations: 16rows | ||

| 3. Material of Roller: 45# steel, Hard chromium plating | ||

| 4. Diameter of main shaft:70mm | ||

| 5. Chain: 1.0 inch | ||

| 6. Thickness of sheet: 0.13-0.4mm Galvanized sheet | ||

| 7. Power of main motor:5.5kw | ||

| 8. Forming Speed:8-15m/minute | ||

| 9. Side plate thickness: 20mm | ||

| 10. Equipment base: 300H steel | ||

| 4 | Cutting device | 1. Material of blade: CR12, heat treatment HRC60-62 |

| 2. Cutting device: self length, self counting, automatic stop cutting, control length | ||

| 3. Cutting way: Four guide post shear device | ||

| 5 | Hydraulic system | 1. Oil pump station:1set, CB-E310 |

| 2. Motor power of pump station: 4kw | ||

| 6 | Electrical System | 1. PLC and HMI touch Screen:Taiwan Delta |

| 2. Frequency converter: 11kw(Mitsubishi) | ||

| 3. Automatic length measurement, Automatic quantity measurement | ||

| 4. Length measurement: Rotary Encoder | ||

| 5. Power: 380V/50Hz/3PH | ||

| 7 | Machine Size | 1. Size( L×W×H): about 7.2m×1.4m×1.5m |

| 8 | Weight of the production line | 1. Total weight: about4.0T |

| 9 | Process of the production line | 1. Decoiler —Forming — Cutting |

| 10 | Warranty and production time | 1. Payment Terms: 30% deposit in advance, balance should be paid before delivery |

| 2. Delivery Time: 25-35 days | ||

| 3. Warranty: Two years since the machine leave seller's factory | ||

Detailed Images

|

Decoiler Pic just for reference,It is used to stand the steel coil and uncoil, keep them working stably. Loading capacity: 3tons |

|

|

Hydraulic cutting Controlled by oil pump Automatic cutting as target products length Blade material: Cr12, quenching treatment |

|

|

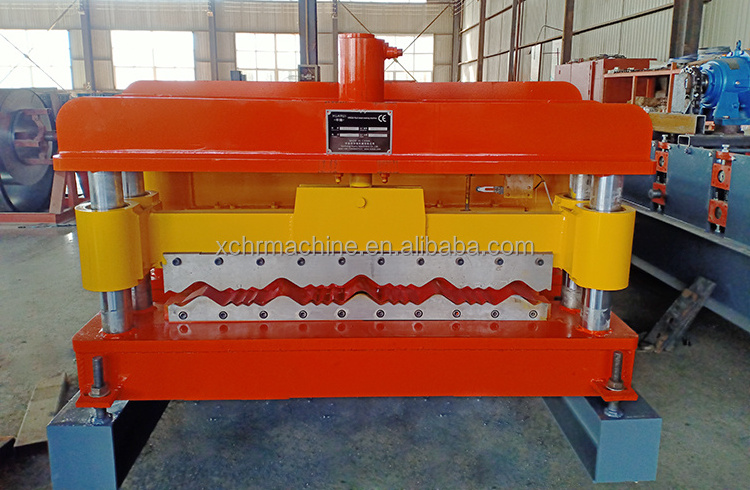

Roll forming body Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped |

|

|

computer control system Button press and screen touch operate Target piece`s length is adjustable Work automatically The system operate easily |

|

|

Pump station Hydraulic oil into the hydraulic oil tank, the pump drives the cutter work Hydraulic oil: 46# Oil add capacity: oil add 3/4 of box capacity Oil pressure: 8-10 MPa |

Finished Products available

Ada Wang (Mobile/Whatsapp/Wechat): +8613569926370

More machines pictures of corrugated metal sheet forming machine

Application of corrugated metal sheet forming machine

Packing and Shipping

Our Service

1. BEFORE ORDER

Before customer start to order machine to us, we have special staff to provide reasonable solution according to customer’s

demands.

2.INSTALLATION AND TRAINING

A.If buyers visit us and check the machine, we will teach you how to install and use the machine, and also train your

workers/technician face to face.

B.Without visiting, we will send you user manual and video to teach you to install and operate.

C.If buyer needs our technician to go to your local factory, we can despatch our technician to help you install the machines. But it is a paid service.

3. AFTER SERVICE

A.Two years guarantee for whole machine.

B.24 hours technical support by email or calling.

C.If there is any problem found of the machine, we will help you replace the damage parts or teach you how to repair it.

Related Products

|

Barbed Wire making machine |

Wire mesh making machine |

Roofing nail making machine |

|

Nail making machine |

Self drilling screw forming machine |

Screw bolt making machine |

Please do not hesitate to contact us for more machines details and latest prices if you are interested in our machines

Ada Wang (Mobile/Whatsapp/Wechat): +86 13569926370