- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

VANEST

-

Dimension(L*W*H):

-

2700*1200*1700 mm

-

Power (kW):

-

37

-

Weight (T):

-

2.8

-

Name:

-

Mini Shredder Machine

-

Application:

-

Recycle Waste Plastic

-

Model:

-

CR400~CR2000

-

Input material:

-

Waste cables and wires, woods, PET bottle, tires, etc

-

Function:

-

Waste materials size reducing

-

After Warranty Service:

-

Video technical support

-

Advantage:

-

Continuous working environment friendly

-

Operation:

-

Automatic

-

Voltage:

-

single phase three phase customize

-

Capacity:

-

150kg/h~2000kg/h

Quick Details

-

Max.Production Capacity (kg/h):

-

1500

-

Place of Origin:

-

China

-

Production Capacity (kg/h):

-

150 - 1500 kg/h

-

Brand Name:

-

VANEST

-

Dimension(L*W*H):

-

2700*1200*1700 mm

-

Power (kW):

-

37

-

Weight (T):

-

2.8

-

Name:

-

Mini Shredder Machine

-

Application:

-

Recycle Waste Plastic

-

Model:

-

CR400~CR2000

-

Input material:

-

Waste cables and wires, woods, PET bottle, tires, etc

-

Function:

-

Waste materials size reducing

-

After Warranty Service:

-

Video technical support

-

Advantage:

-

Continuous working environment friendly

-

Operation:

-

Automatic

-

Voltage:

-

single phase three phase customize

-

Capacity:

-

150kg/h~2000kg/h

Shredding machine product advantages:

1. The blade holder and blade on the rotor can be disassembled for easy cleaning, maintenance

and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear to continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4. Adopt PLC program control system, can automatically reverse, make the machine run stably;

5. The box body is welded and tempered after welding to eliminate the welding stress;

6. The installation position of moving knife is precisely machined by machining center to ensure that the clearance between each moving knife and fixed knife is the same;

7. The moving tool holder is embedded in the tool shaft with high strength screws. On, can prevent welding type after long-term vibration caused by the phenomenon of knife drop.

8. Convenient transportation after tearing, can reduce transportation cost, increase transportation efficiency, convenient secondary processing.

and maintenance;

2. Each moving knife has 4 cutting edges, which can be rotated 90° after wear to continue to use;

3. The main shaft is driven by the gear reduction box, running smoothly, low noise, large torque;

4. Adopt PLC program control system, can automatically reverse, make the machine run stably;

5. The box body is welded and tempered after welding to eliminate the welding stress;

6. The installation position of moving knife is precisely machined by machining center to ensure that the clearance between each moving knife and fixed knife is the same;

7. The moving tool holder is embedded in the tool shaft with high strength screws. On, can prevent welding type after long-term vibration caused by the phenomenon of knife drop.

8. Convenient transportation after tearing, can reduce transportation cost, increase transportation efficiency, convenient secondary processing.

|

Model

|

Power(kw)

|

Size (mm)

|

Blades Shaft Diamter

(mm)

|

Reducer Model

|

Weight

|

|||||

|

V-CR400

|

5.5kw*2

|

2100*1000*1500

|

200mm

|

ZQ350

|

1300KG

|

|||||

|

V-CR600

|

7.5kw*2

|

2400*1030*1700

|

220mm

|

ZQ400

|

2300KG

|

|||||

|

V-CR800

|

18.5kw*2

|

2700*1200*1700

|

260mm

|

ZQ500

|

2800KG

|

|||||

|

V-CR1000

|

30kw*2

|

4000*1700*2200

|

380mm

|

ZQ650

|

4500KG

|

|||||

|

V-CR1200

|

37kw*2

|

4200*1750*2200

|

400mm

|

ZQ750

|

5200KG

|

|||||

|

V-CR1400

|

45kw*2

|

4500*1780*2300

|

450mm

|

ZQ750

|

6500KG

|

|||||

|

V-CR1600

|

75kw*2

|

5000*1920*3200

|

500mm

|

ZQ850

|

13000KG

|

|||||

|

V-CR1800

|

110kw*2

|

6500*2300*3800

|

600mm

|

ZSY500

|

32000KG

|

|||||

|

V-CR2000

|

132kw*2

|

7500*2500*4200

|

650mm

|

ZSY560

|

40000KG

|

|||||

|

* Voltage: 380V/220V/ customized to client's local condition.

|

|

|

|

|

|

|||||

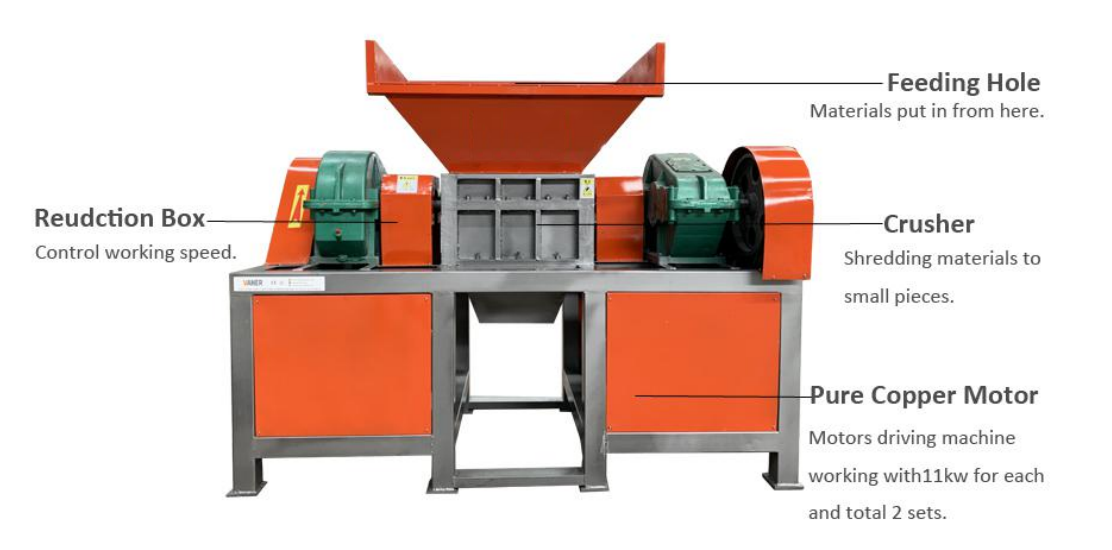

MACHINE STRUCTURE

MORE MACHINE PICTURES

Hot Searches