2. Bridge structure and logical control system ensure a stable performance;

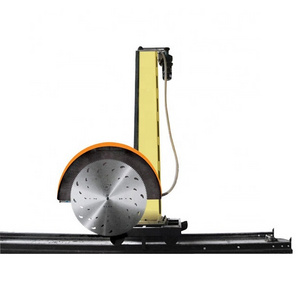

3. Blade combinations in different diameters work simultaneously;

4. Complete with hydraulic lifting system (optional)The lifter moving up and down is driven 4 pillars by oil hydraulic pressure cylinder (or by lead screw).;(It has screw-rod lifting system and hydraulic lifting system for choice.)

5. Complete with oil-immersed guide rail for crossbeam and side beam; 6. working principle: The

machine blades moving in left and right direction is controlled variable-frequency drive (VFD) and the speed will be adjusted depend on the hardness of the stone; 7. Rotary table (optional); 8. The lead pillar is made of high quality solid round steed plated with hard chromiumand the diameter of one pillar reach 180mm, with automatic lubricating; 9. Blade combinations are flexibly decided according to specific customer need. 10. Beam length range can be adjusted according to sawing feeding length, customer range 6m to 9m.

machine blades moving in left and right direction is controlled variable-frequency drive (VFD) and the speed will be adjusted depend on the hardness of the stone; 7. Rotary table (optional); 8. The lead pillar is made of high quality solid round steed plated with hard chromiumand the diameter of one pillar reach 180mm, with automatic lubricating; 9. Blade combinations are flexibly decided according to specific customer need. 10. Beam length range can be adjusted according to sawing feeding length, customer range 6m to 9m.