- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

55000*5000*6000mm

-

Weight:

-

30000 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Service:

-

Online support

-

Techinal support:

-

Video technical support

-

Name:

-

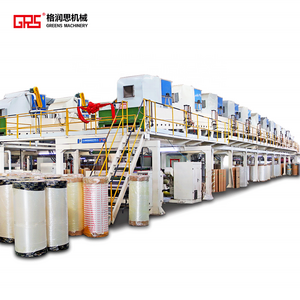

BOPP Coating Machine

-

Coating method:

-

Mayer Bar

-

Function:

-

applying glue to the BOPP film

-

Coating width:

-

1300/1600mm

-

Adavantages:

-

HIgh Speed to 400m/min

-

Glue type:

-

Water-based Acrylic

-

Heating:

-

Optional as customers'requested

Quick Details

-

Voltage:

-

380/3P

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

xinwang

-

Dimension(L*W*H):

-

55000*5000*6000mm

-

Weight:

-

30000 KG

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Service:

-

Online support

-

Techinal support:

-

Video technical support

-

Name:

-

BOPP Coating Machine

-

Coating method:

-

Mayer Bar

-

Function:

-

applying glue to the BOPP film

-

Coating width:

-

1300/1600mm

-

Adavantages:

-

HIgh Speed to 400m/min

-

Glue type:

-

Water-based Acrylic

-

Heating:

-

Optional as customers'requested

400m/min BOPP Adhesive Tape Jumbo roll Coating Machine

|

NO. |

DETAILS |

|

1 |

machine technology guidance |

|

2 |

installment,testing and debug |

|

3 |

trial production in your factory |

|

4 |

raw materials support, introduce suppliers |

|

5 |

technicians' training |

|

6 |

help to purchase raw materials |

|

7 |

cost analysis |

|

8 |

other necessary support and after-sale service |

For the coating machines, we have successfully manufacture the first and second generation models, gathering with experience and technology, we upgraded and developed the new generation coating machine.

Several Data To Witness the Improvement for the new generation BOPP Adhesive tape Mayer bar Coating Machine

1.Coating thickness could be from 6um-26um , depends on different material.

2.Glue thickness error within +/-1.0um.

3.The fastest coating machine in China for Bopp and Opp films, could reach 350m/min .

4.Temperature deviation within 2℃ .

5.Solid Content add 5%, that means the percentage of gum water decreased.It's really cost saving.

6.With exclusive drying system,

25%

energy saved than the similar products on market.

Main Features:

A30mm armor plate with structural steel for body frame.Makes nice appearance and stability even under high working seepd.

B.Real time monitor system: temperature, unwind and rewind tension, airflow speed all could be supervised and adjusted through human-coumputer interface.To ensure the coating machine always in best working condition.

C.Coatiing Head could be customized according to the coating material and the gule water .The coating thickness variation could be controlled within +/-1.5um.Anyway,We will provide you the best production scheme with our rich experience in the industry.

D. Various heating Source could be choosen. Electricity,nature gas, bio-energy ,coal and even nuclear energy.Buyer can according to the condition of his own country and choose the most economical and enviromental-friendly mode.

E.360°Rotary tape unwinding and 180°tumblet type rewinding.Very easy for operating and labor saving.

F.Auto edge deviation with EPC unit. Make sure the finish rollers with very smooth edge.The edge neatness within 2mm.

Technical Parameters:

|

Machine Name |

Automatic High Precision Coating machine |

|

|

Model |

XW-1300 |

XW-1600 |

|

Material |

BOPP ADHESIVE TAPE ,BOPP PACKING TAPE |

|

|

Voltage(V/Hz) |

3Phase 80V 50HZ |

|

|

Effective work width |

1300mm/ 1600mm |

|

|

Max. unwinding diameter |

700mm |

|

|

Max. rewinding diameter |

800mm |

|

|

Inner diameter of core |

76.2mm |

|

|

Heating System |

As clients’ requirements |

|

Different machine models with different lead time, for the Automatic High Precision Coating machine,

Production Time: 30 to 75 working days after receiving the deposit

Packaging Type: seaworthy wooden case

- 12 months warranty (except for spare parts)

- 24 hours online service

- Providing free quick-wear parts

-

Engineers available to service overseas if necessary

Q:How Can I go to your factory?

A:Our factory locates at Qinghu industrial park of Qishi town,Dongguan,Guangdong,China.There are many convenient roads to arrive here.You can by air to Guangzhou or Shenzhen international airport and then take the fast train(CRH) to Changping train station(it takes about 1 huor). We will send a car to pick you up from the station.

Q:How does your factory do regarding quality control.

A:Quality is the soul of an enterprise.We have a strict quality management system.Every worker in every department has his/her responsibilities to ensure the machines we made are of highest quality. From even small conponents purchasing to processing,then to assembling and every part's installation,including painting,debugging,and at last packing,everyone should be conscientious and meticulous.Top management have the Technical Seminar every month to analyze the questions we met and find good way for improvement.