Furniture industry: cabinet doors, wooden doors, solid wood, panel, doors and windows, tables and chairs.

Decoration industry: screen, wave board, large wall hanging, advertising board, logo production.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4700*950*1750mm

-

Power (kW):

-

5

-

Weight (KG):

-

1400 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Usage:

-

Furniture Production

-

After-sales Service Provided:

-

Overseas service center available

-

Power sorce:

-

380V+N/50Hz

-

Machine size:

-

4700*950*1750mm

-

Machine weight:

-

1400kgs

-

Band thickness:

-

0.4-15mm

-

Name:

-

Eage Banding Machine

-

Application:

-

Kitchen Cabinet

-

Model:

-

zd500

-

Color:

-

Customer Actual Requirements

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zhngding

-

Voltage:

-

380V(options)

-

Dimension(L*W*H):

-

4700*950*1750mm

-

Power (kW):

-

5

-

Weight (KG):

-

1400 kg

-

Panel Feed Speed(m/min):

-

15m/min

-

Usage:

-

Furniture Production

-

After-sales Service Provided:

-

Overseas service center available

-

Power sorce:

-

380V+N/50Hz

-

Machine size:

-

4700*950*1750mm

-

Machine weight:

-

1400kgs

-

Band thickness:

-

0.4-15mm

-

Name:

-

Eage Banding Machine

-

Application:

-

Kitchen Cabinet

-

Model:

-

zd500

-

Color:

-

Customer Actual Requirements

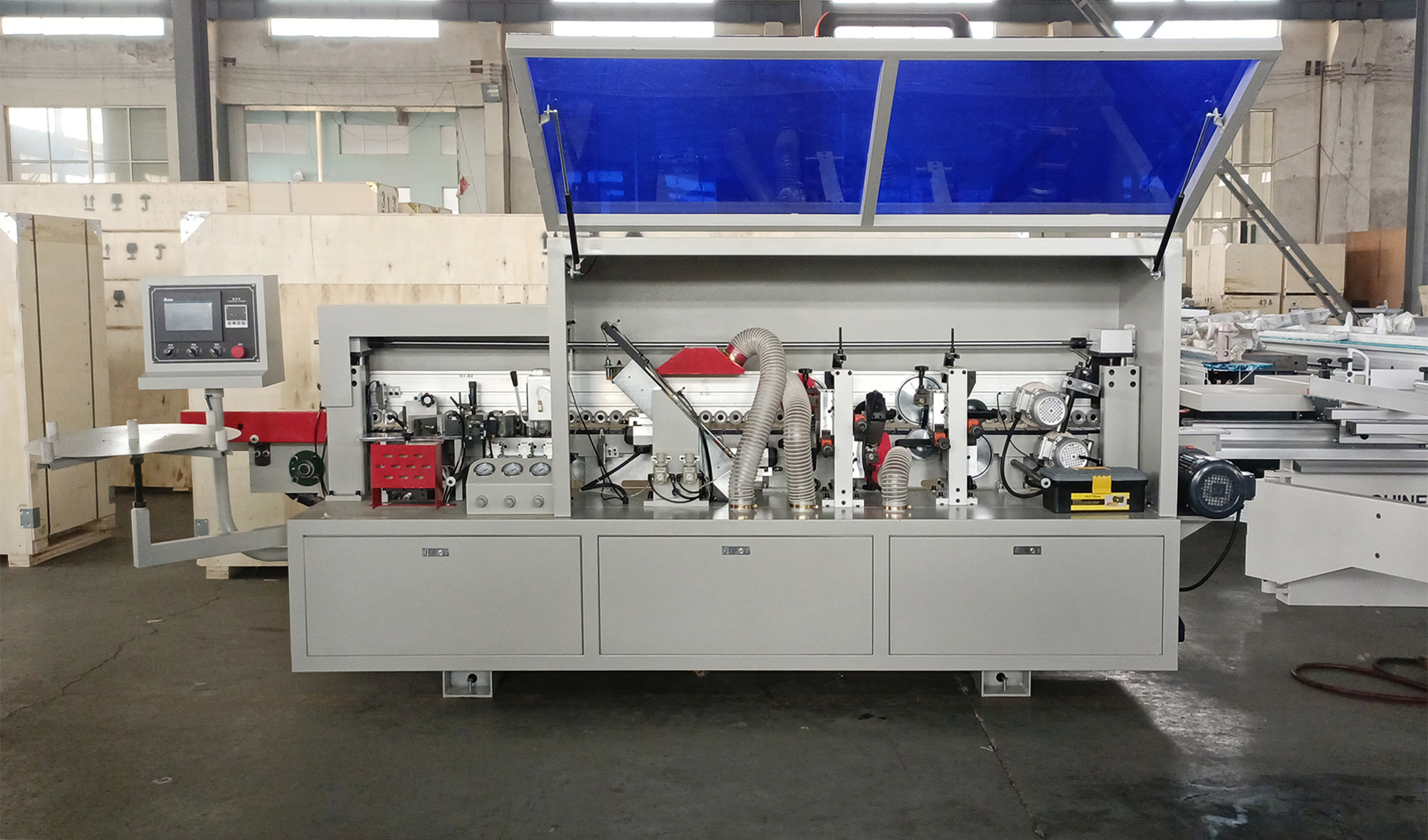

Wood ZD500 Edge Banding Machine for Wood Furniture

Appliance

|

Model NO.

|

ZD500

|

Panel thickness

|

10-60mm

|

|

Working pressure

|

0.6MPa

|

Panel length

|

Min.150mm

|

|

Total power

|

13.75kw

|

Panel width

|

Min.50mm

|

|

Feeding speed

|

13m/min

|

Edge thickness

|

0.4-3mm

|

|

Overall size

|

3670*900*1590mm

|

Weight

|

1450KG

|

Customization

As a manufacturer, we can meet any requirement of Edge Banding Machine. Whether it is the technical specification of the machine or the brand of accessories, as well as different functions, you have many choice. Build a custom woodworking cnc machine that only belongs to you!

Specification

Full Automatic edge banding machine

ZD500 has 5 main Functions : Gluing, End trimming, Fine trimming, Scraping, Buffing.

PLC

PLC control, operation more easy.

PLC control, operation more easy.

Gluing

The glue pot adopts imported special ball bearing and high hardness and super wear-resistant material glue box, the glue lifting

shaft is patented design, CNC processing, to ensure the glue output, uniform daub, the glue surface hit 99.999%, the glue

thickness can be controlled at will.

The glue pot adopts imported special ball bearing and high hardness and super wear-resistant material glue box, the glue lifting

shaft is patented design, CNC processing, to ensure the glue output, uniform daub, the glue surface hit 99.999%, the glue

thickness can be controlled at will.

End trimming

The end trimming system is used to cut off the cutting components of the front and rear edge tape. The end trimming device moves

through precise linear guides, adopts automatic profiling and high-frequency electrode rapid cutting mechanisms to ensure that the cut surface is flat and smooth.

The end trimming system is used to cut off the cutting components of the front and rear edge tape. The end trimming device moves

through precise linear guides, adopts automatic profiling and high-frequency electrode rapid cutting mechanisms to ensure that the cut surface is flat and smooth.

Fine trimming

Fine trimming devices are used for trimming and processing the excess edge banding material on the upper and lower parts of the sheet edge banding. It adopts the structure of automatic profiling and high-frequency high-speed motor, etc. To ensure the smoothness of the upper and lower parts of the trimmed board edge.

Scrapping

The scrapping is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming, so that the upper and lower parts of the sapwood are smoother and cleaner, and the edges are scraped. Updated scraping mechanism with bigger unit and big copy wheel and V shape blade to get better effect.

Buffing

Component polishes the edge and removes the sol residue on the workpiece. The polishing device uses a cotton polishing wheel to clean the processed plate. The edge-sealing end surface is smoother through polishing. The polishing component used for the upper surface of the workpiece is fixed on the workpiece.

Factory

Qingdao Zhongding Machinery Co., Ltd is a leading company of specializing in manufacturing and exporting woodworking machine for more than 20 years. We perform a variety of services to not only supply our clients with top quality woodworking machinery but also adequate maintenance, spare parts and technical advice.

Our products mainly include CNC machine , Precise Panel Saw, Edge Banding Machine, Multiple Drilling Machine, Press Machine etc., which have been exported to lots of countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, and Australia.

We have established complete sales system.Our company has got ISO9001 international system certificate and CE security certificate.

Our products mainly include CNC machine , Precise Panel Saw, Edge Banding Machine, Multiple Drilling Machine, Press Machine etc., which have been exported to lots of countries and regions, such as Europe, Russia, Southeast Asia, Middle East, North America, and Australia.

We have established complete sales system.Our company has got ISO9001 international system certificate and CE security certificate.

RFQ

Edge banding machine

1. What function of edge banding machine is needed?

1. What function of edge banding machine is needed?

The basic functions are gluing, end trimming, fine trimming, scraping, and buffing. Rough repair, pre-milling, corner trimming, slotting, thermal transfer, etc. can all be selected according to your processing requirements.

2. What is the final product to be produced?

If you are processing large quantities of simple edge banding plates, you can choose R series or 450D edge banding machines. If processing customized boutique cabinets, etc., it is recommended to choose 450A, 450C series of edge banding machines.

3. What is the thickness of the commonly used edge banding?

If the thickness of the edge band exceeds 1.5mm, the function needs to be double trimming to ensure the perfect edge banding effect. If the distance between the two sides of the edge banding is more than 1mm, you need to choose a machine with double trimming function, otherwise there will be waves on the edge of the edge banding.

4. What is the target market facing?

According to the market situation, we can customize the edge banding machine that meets the expectations according to the effect of market demand.

5. What is the material of the edge banding?

5. What is the material of the edge banding?

Our machine is mainly suitable for edge banding of 0.5-3mm material, if it is wood strip and other materials need to be confirmed

6. What brand and configuration of the machine currently in use?

It can be positioned according to the functional brand of the machine currently in use, and it is accurately recommended.

7. What are the specifications of the supporting machines?

If the panel saw has a long service life or is a low-profile panel saw, it is recommended that customers add pre-milling function.

PACKAGE:

LCL SHIPMENT: Use plastic foam protect ,then ply wooden case package.

FCL: If the equipment enough packagewith 20"or 40" container ,will use plastic foam package and wooden pallet.

SHIPPING TERMS:

1. We can arrange the shipping by sea, by air ,by truck and train based on your requirements, but kindly remind the refrigerant gas can't allowed by air ,so you must filling them whenmachine arrive if you choose the air ship.

2. FOB,CNF,CIF,DDU can be accepted.

3. Any port of CHINA we can sent ,if you have other goods will packaged in one container ,we would like to arrange that for you.

LCL SHIPMENT: Use plastic foam protect ,then ply wooden case package.

FCL: If the equipment enough packagewith 20"or 40" container ,will use plastic foam package and wooden pallet.

SHIPPING TERMS:

1. We can arrange the shipping by sea, by air ,by truck and train based on your requirements, but kindly remind the refrigerant gas can't allowed by air ,so you must filling them whenmachine arrive if you choose the air ship.

2. FOB,CNF,CIF,DDU can be accepted.

3. Any port of CHINA we can sent ,if you have other goods will packaged in one container ,we would like to arrange that for you.

Hot Searches