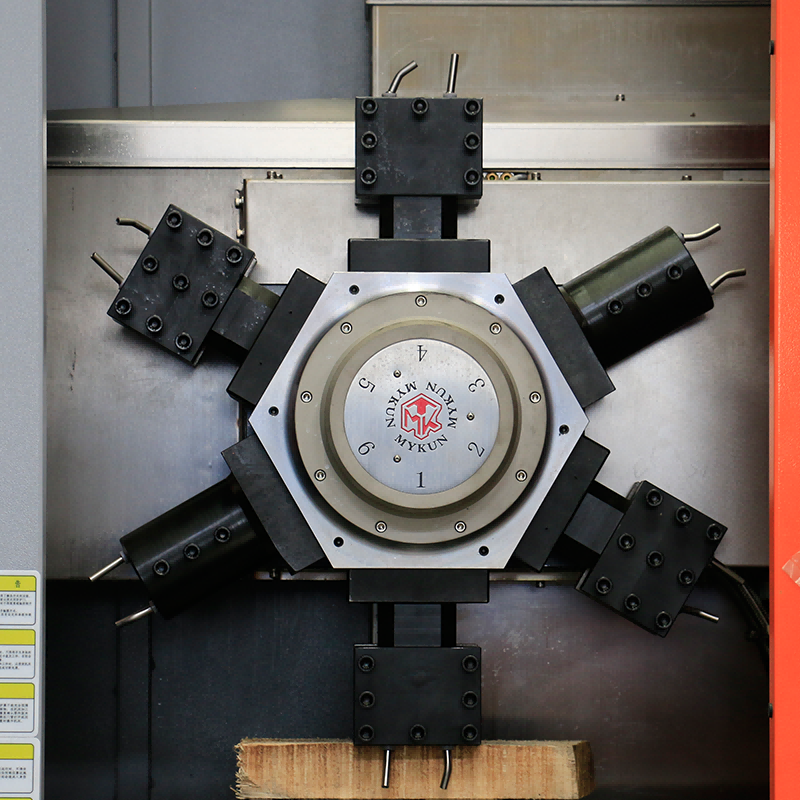

The machine tool rest adopts horizontal or vertical multi-station CNC tool rest, which shortens the tool changing time and greatly improves work efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

1000 r.p.m

-

Spindle Bore(mm):

-

160

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

18.5

-

Travel (X Axis)(mm):

-

425 mm

-

Travel (Z Axis)(mm):

-

690 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2200*2050*2910

-

Brand Name:

-

Taiyun

-

Model Number:

-

VTC60

-

Voltage:

-

380

-

Weight (KG):

-

7500

-

Spindle power:

-

18.5KW

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

CNC or Not:

-

CNC

-

Spindle Speed Ranges:

-

100-1000

-

Product name:

-

CNC Lathe Mechine

-

After-sales Service Provided:

-

Online Support

-

Turret Type:

-

4/6/8 Station Electric Turret

-

Precision:

-

0.003mm

-

Processing type:

-

High Precision Heavy Duty

-

Chuck size:

-

18 inches

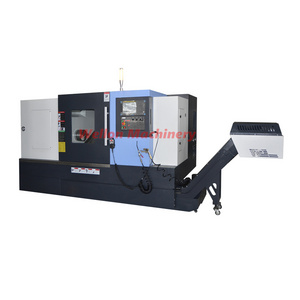

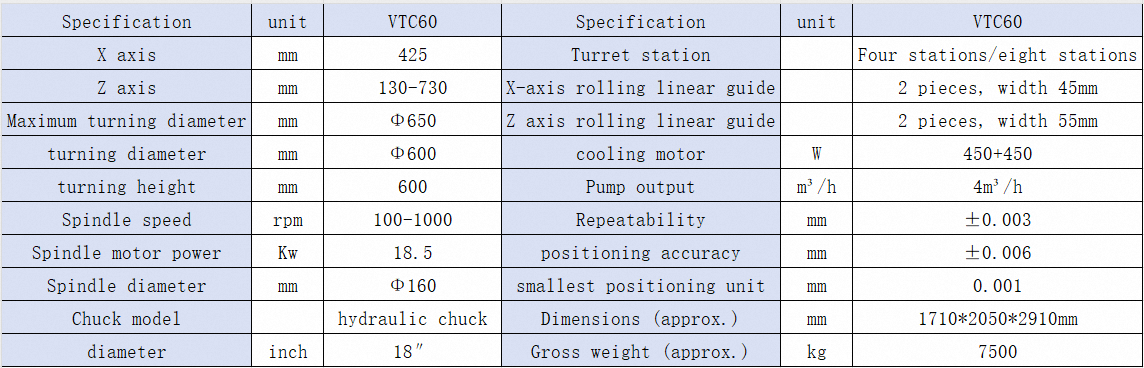

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

650

-

Year:

-

2024

-

Max. Spindle Speed (r.p.m):

-

1000 r.p.m

-

Spindle Bore(mm):

-

160

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

18.5

-

Travel (X Axis)(mm):

-

425 mm

-

Travel (Z Axis)(mm):

-

690 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2200*2050*2910

-

Brand Name:

-

Taiyun

-

Model Number:

-

VTC60

-

Voltage:

-

380

-

Weight (KG):

-

7500

-

Spindle power:

-

18.5KW

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

CNC or Not:

-

CNC

-

Spindle Speed Ranges:

-

100-1000

-

Product name:

-

CNC Lathe Mechine

-

After-sales Service Provided:

-

Online Support

-

Turret Type:

-

4/6/8 Station Electric Turret

-

Precision:

-

0.003mm

-

Processing type:

-

High Precision Heavy Duty

-

Chuck size:

-

18 inches

Products Description

02

The machine tool equipment uses imported silver wire rods and guide rails, which greatly improves the positioning accuracy and load-bearing capacity of the machine tool's vertical and horizontal feed movements.

03

The electronic oil pump automatically lubricates regularly and operates stably and reliably.

04

The air conditioning system can effectively control the ambient temperature and humidity to ensure the normal operation of the machine tool.

05

The machine tool can be equipped with a mechanical spindle or an electric spindle to meet the different requirements for spindle speed for rough machining and finishing of parts.

The features of vertical lathes provide for highly accurate, stable machining.Since the adhesive weight of a workpiece helps clamp it to the chuck's reference surface.

This prevents workpiece warp, and accommodates thin, large-diameter, or heavy workpieces. With fixtures for odd-shaped components, manual part load/unload (without holding the part in place) is also easy.

Advanced, highly rigid construction enables powerful and very accurate machiningA rock-solid rectangular column is firmly secured to a rigid base with excellent damping performance. Minimal tool-to-column guideway distance assures the rigidity needed to withstand heavy-duty cutting loads. Moreover, the box ways for the X and Y axes help to achieve heavy-duty cutting of big components at high accuracies.

Innovative shop floor productivity in many types of production

This gives the maximum productivity with the minimum floor space by shortening lead times and cutting down on intermediate work in progress. The separated right-left structure also enables stable machining that is unaffected by the machining vibration of the other spindle. Compact lines that minimize robot travel can be built.

|

Fittings of a machine

|

Hydraulic station

Electronic oil pump

CNC system

Principal axis

Air-conditioning

Oil circuit

Recommend Products

CK525

KD

VTC

Vertical machining center

CNC gantry machining center

Horizontal machining center

Hot Searches