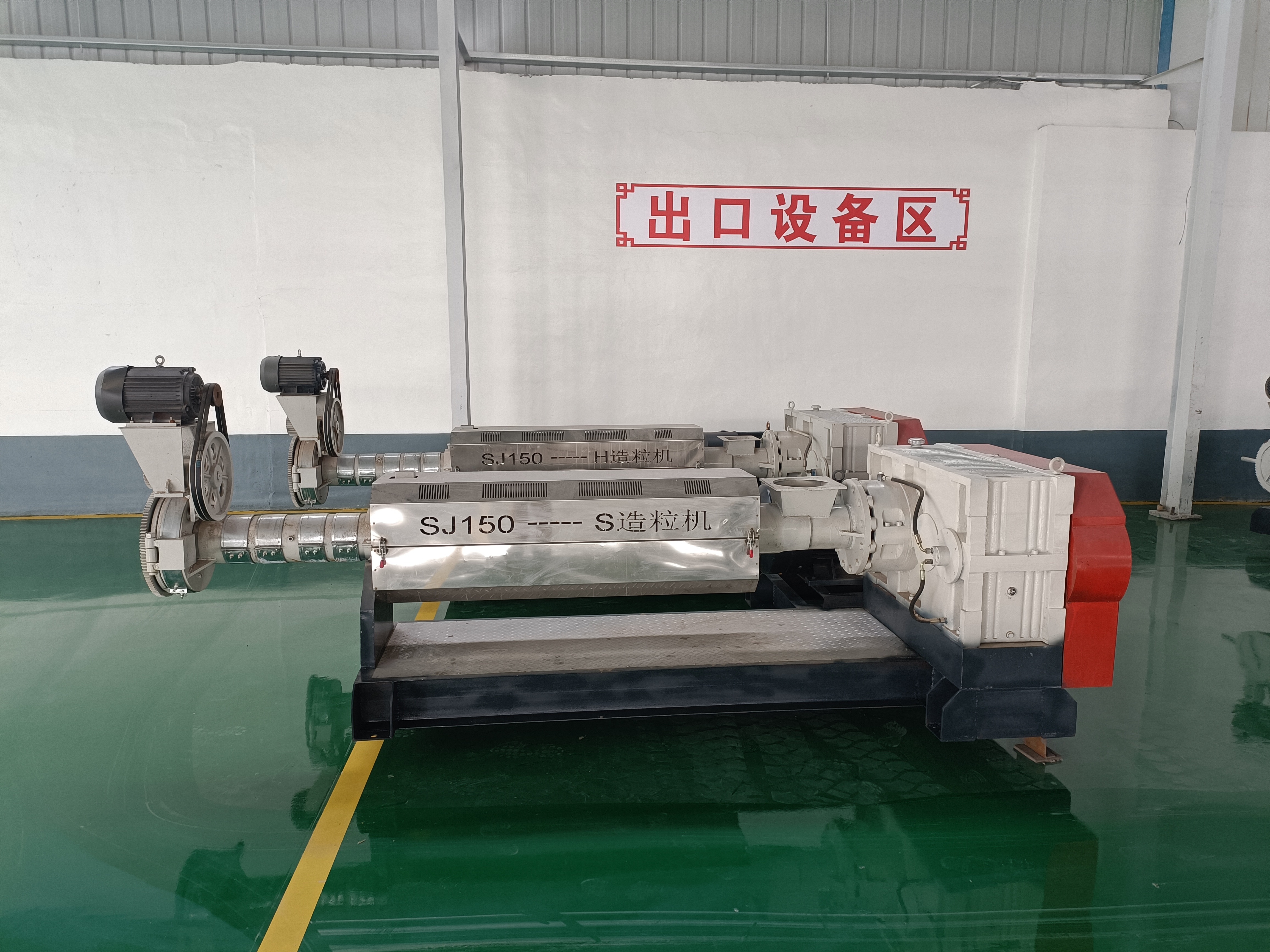

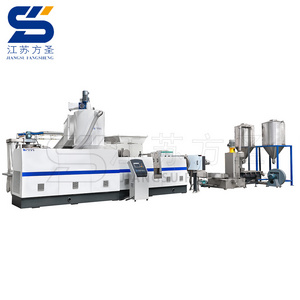

Different from the traditional pelletizing line, this plastic pelletizing machine all-in-one machine pays more attention to protect the physical properties of plastic and can keep the plasticity, toughness and durability of the original plastic as much as possible. The advantages of this machine are high output and low energy consumption. It is worth noting that the plastic pellets produced by this machine are firm, full and shiny.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500*1500*1200cm

-

Power (kW):

-

30kw-6 level

-

Weight:

-

2000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

Mainframe screw:

-

125*2700mm

-

Speed reducers:

-

JZQ500

-

Mainframe barrel:

-

159*2700mm

-

Mould head:

-

360 mould head, 2.2Kw - 6 stage motor

-

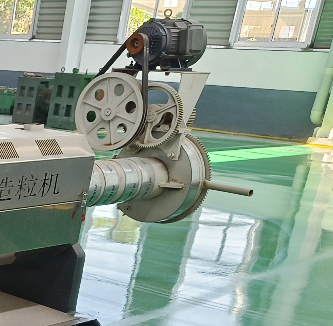

Granulator:

-

9 blade type, 3kw/4 stage motor

-

Receiving hopper:

-

950*680*450mm

-

Cooling sink:

-

3000*400*240mm

-

Applicable materials:

-

PP, PE, PT, ABS, PS and other hard plastics

-

color:

-

White orange or Bespoke on request

-

Host heating ring:

-

159*100*2kw*5

Quick Details

-

Output (kg/h):

-

100 - 300 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Quanshun

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2500*1500*1200cm

-

Power (kW):

-

30kw-6 level

-

Weight:

-

2000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

Mainframe screw:

-

125*2700mm

-

Speed reducers:

-

JZQ500

-

Mainframe barrel:

-

159*2700mm

-

Mould head:

-

360 mould head, 2.2Kw - 6 stage motor

-

Granulator:

-

9 blade type, 3kw/4 stage motor

-

Receiving hopper:

-

950*680*450mm

-

Cooling sink:

-

3000*400*240mm

-

Applicable materials:

-

PP, PE, PT, ABS, PS and other hard plastics

-

color:

-

White orange or Bespoke on request

-

Host heating ring:

-

159*100*2kw*5

Product Description

Product advantages and functions introduction

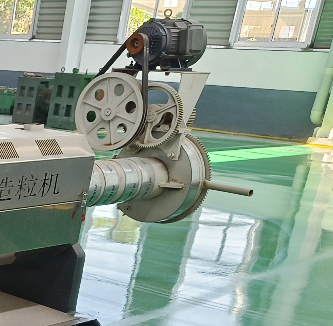

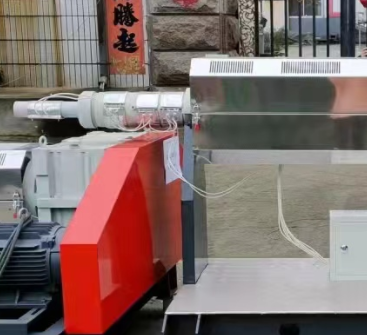

Mold head

Extruding plastic strips for the next cooling step.

Electric heating ring

The final heating of the material makes the material plasticized evenly and the product granules are full and shiny.

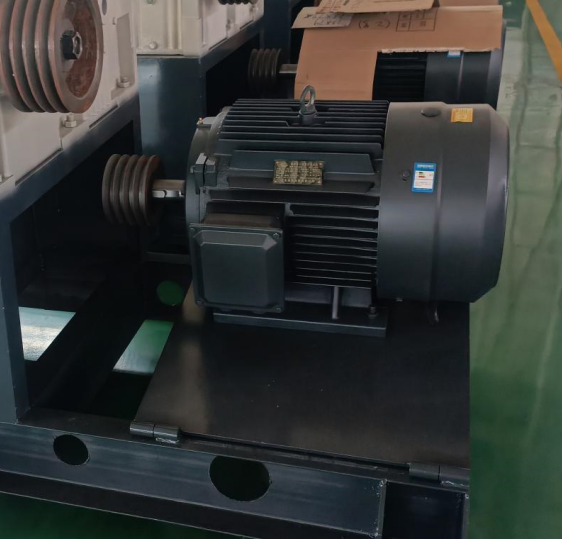

Motor

Provide continuous and stable power for the whole machine.

Suitable materials for processing

Warm Tips

How to understand old plastic

Old plastic is a colloquial term that does not refer to waste, useless plastic products. The vast majority of plastic products, whose plastic material properties have not changed significantly after use, can be completely recycled, processed in an appropriate way, and used again. Therefore, the more formal term for old plastic is post-consumer plastic scrap.

Common types of recyclable plastics

For examples:

PP, PE, ABS, PA, PS,

PET, HDPE, LDPE, PVC

Types of plastics for which this series of machines is suitable

This machine can be used to pelletize many types of plastics such as

PP PE PT ABS PS PVC PET/PETP EPS HDPE LDPE , hard

plastics, soft plastics and other plastic products

.

|

Specification parameters

|

|

|

|

|

||||

|

Product Name

|

Plastic pelletizing machine integrated machine

|

|

|

|

||||

|

System Components

|

Crawler Feeder/Plastic Crusher/Vertical mixing cylinder/ Feeding conveyor/Plastic pelletizing machine/Cooling water tank/Granulator/Vibrating granule sifter/Storage cylinde

|

|

|

|

||||

|

Target processing materials

|

PP, PE, PT, ABS, PS, PET, PVC and other types of plastics

|

|

|

|

||||

|

Final Product Shape

|

Particles

|

|

|

|

||||

|

Model

|

125H

|

125S

|

150H

|

150S

|

|

Production Capacity(kg/h)

|

100-150

|

100-150

|

200-300

|

150-200

|

|

Screw Diameter (mm)

|

125

|

125

|

147

|

147

|

|

Screw Length(mm)

|

2700

|

2700

|

2800

|

2800

|

|

Motor Power(kw)

|

30kw-6 level

|

30kw-4 level

|

55kw-6 level

|

55kw-4 level

|

|

Speed Reducer

|

JZQ500

|

JZQ500

|

JZQ500

|

JZQ500

|

|

Heating Method

|

Induction heating

|

Induction heating

|

Induction heating

|

Induction heating

|

|

Forced feeder

|

|

2.2kw motor

|

|

2.2kw motor

|

|

Mould head heating ring

|

360*60*3kw*1pc

|

360*60*3kw*1pc

|

410*60*4kw*1pc

|

410*60*4kw*1pc

|

Structure and details introduction

Crawler Feeder

This machine is a supporting machine required for plastic processing machinery, which can convey plastic raw materials (whole

plastic or broken plastic) directly to the crusher inside or granulator inlet. The part in contact with the material is made of

stainless steel, and the raw material is completely free from pollution during the conveying process, so that the production

process can be fully enclosed and automated.

Plastic Crusher

The machine is mainly used for the crushing of hard and soft plastics.

Vertical mixing cylinder

The vertical mixer collects and mixes the preliminarily crushed material.

Feeding conveyor

The machine is used to convey the crushed material to the granulator inlet.

Mould head

The extrusion die extrudes the plastic strip in its molten state and into a subsequent cooling cell.

Cooling water tank

For cooling the extruded hot melt plastic strips.

Blow dryers

Blowing machine to remove moisture and dry the extruded hot melt plastic strips.

Granulator

Applicable to most common waste plastics, it is a widely used recycling processing machine in the waste plastics recycling industry. The extruded hot melt plastic strips are cut into granules for operation, and the granules are full and shiny

.

Storage steel barrels

Collect the cut plastic pellets in the steel cylinder.

Plastic pelletizing whole process diagram

This is a diagram of the entire plastics pelletizing process, and contains almost all the plastics machinery you may need.

The parameters of the machinery can be adjusted according to your needs.

Logistics at a glance

Attached to the surface of the machine is a water barrier anti-rust pigment coating.

We wrap the machine with plastic film to ensure a clean and tidy surface for transport to the destination.

The machine is put into the shipping container and will be fixed on special brackets to ensure that the machine is not damaged during transportation. We choose a reliable partner and a safe shipping container .

More products you may like

Feeder Loaders

Foam cold press recycling machine

Crawler Fee

de

r

When you choose us, you choose peace of mind

Our honors and credit certifications

Industry quality standardization qualification level certificate

In 2020, our company obtained the first-class certificate of the industry issued by "Beijing Audit and Verification Enterprise Credit Assessment Center" and "Beijing Jian Youpin Quality Certification Center".

Bidding and bidding enterprise credit rating certificate

In 2019, our company was rated as "AAA grade enterprise" by "Beijing Puhua Zhengxin International Credit Appraisal Company Limited" and "National Enterprise Integrity Public Service Platform Certified Enterprise", and obtained China Bidding Enterprise Credit Rating Certificate.

Responsibility credit evaluation certificate

In May 2020, we were awarded the certificate of "National Product Quality Qualified Red List Unit", which is a certificate of responsibility credit evaluation and is recorded in China's "National Enterprise Credit File Public Notice System".

Our Clients

Our general manager went to Vietnam and took a group photo with the customer outside the customer's new plant.

Foreign customers visit our company and take a group photo at the roadside.

Our general manager traveled to the customer's country to visit the site of the customer's new factory.

Hot Searches