- Product Details

- {{item.text}}

Quick Details

-

Rated Capacity:

-

30KVA

-

Rated Duty Cycle:

-

25%

-

Max. Welding Thickness:

-

2mm

-

Dimensions:

-

900mmX1150mmX1750mm

-

Use:

-

kitchen utensil welding machine

-

Voltage:

-

380V

-

Power (kW):

-

10

-

Weight (KG):

-

300 KG

-

Name:

-

HWASHI Forged Aluminum Frying Pan kitchen utensil welding machine

-

Capacitance:

-

200000uf

-

Electrode Stroke:

-

80kg

-

Closure:

-

180-280mm

-

Rount:

-

100mm

-

Platform Distance:

-

260

-

Electrode Distance:

-

320-420mm

-

Cooling Water:

-

Min 3

-

Input Heat:

-

20000J

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HWASHI

-

Rated Capacity:

-

30KVA

-

Rated Duty Cycle:

-

25%

-

Max. Welding Thickness:

-

2mm

-

Dimensions:

-

900mmX1150mmX1750mm

-

Use:

-

kitchen utensil welding machine

-

Voltage:

-

380V

-

Power (kW):

-

10

-

Weight (KG):

-

300 KG

-

Name:

-

HWASHI Forged Aluminum Frying Pan kitchen utensil welding machine

-

Capacitance:

-

200000uf

-

Electrode Stroke:

-

80kg

-

Closure:

-

180-280mm

-

Rount:

-

100mm

-

Platform Distance:

-

260

-

Electrode Distance:

-

320-420mm

-

Cooling Water:

-

Min 3

-

Input Heat:

-

20000J

Product Description

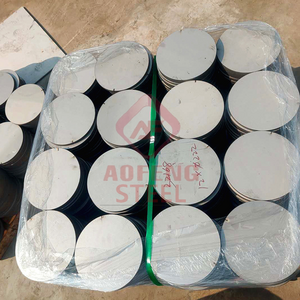

HWASHI Stainless Steel

SS/Al/SS Composite Cook Pot Handle Spot Welding Machine

Detailed Description

Instantaneous current

Welding process passes through thousands of ampere current within 1/1000 second of time.

Minimize oxidation and mechanical deformation.

Output is from 100WS to 18000WS.

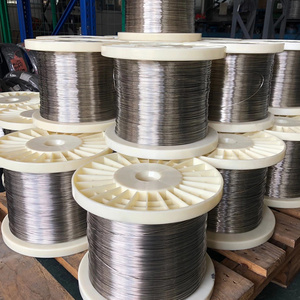

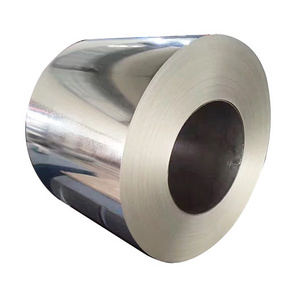

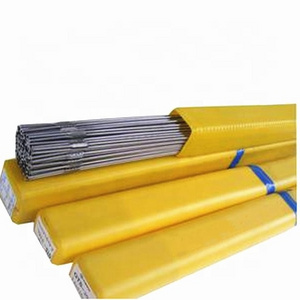

Suitable for welding metals like red copper, bronze, brass, aluminum, silver, stainless steel, etc.

Features

1. Wide application: Be able to weld 8mm of nonferrous metals like stainless steel, aluminum, titanium, silver, etc. Overcome the difficulties in welding dissimilar metals like bronze, aluminum, etc.

2. Firm and beautiful: Firm welding; no black coating on welding spot so no need of polishing; Especially suitable for those products which have high standard of beautiful outlook requirement.

3. Electricity and energy saving: This machine gets low surge power from the power grid and the power factor is high. Compared with the identical welding force frequency machine, it uses only 1/7 to 1/10 of the power. With a low cost.

Applicable Area

Suitable for welding Kitchen utensils, automobile manufacturing, glasses, hardware, household appliances, low-voltage apparatus, elevator, compressor, etc.

Capacitor discharge spot welding machine is a kind of electrical energy storage spot welder, which is used to charge the capacitor after rectifier rectification of AC power, and then the stored electric energy is converted into a low electric voltage, and the energy is relatively concentrated and stable pulse current, then the metal is fused through the resistance heat generated at the contact point of the welding workpiece.

Intelligent welding control system

Intelligent Touch Screen Controller Input and

read

welding parameters, Optional Digital Dial Code Type, Intelligent Microcomputer Type, Touch Screen Type.

Raw materials made to standard

Thicker Copper Plate or Copper Belt To ensure stable conductivity in welding.

Custom processing of electrodes

Customized Electrodes which will be suitable for

Welding material like steel, aluminium, silver, stainless

Steel, and nickel steel.

Welding material like steel, aluminium, silver, stainless

Steel, and nickel steel.

Shape structure and welding method

Design the right machine shape and mold according to

the welding product.

Features of The Capacitor Discharge Spot Welding Machine

1.The requirements for the power grid are low and do not affect the power grid.

2.The welding process is short, the instantaneous current is high, and the heat affected zone is small.

3.The water cooling circulation system helps to effectively reduce the consumption of electrodes and transformers.

4.The welding surface oxidation and deformation is small, no black coating, and no grinding process is required after welding.

Specification

|

Model

|

Input Voltage

|

Input Power

|

Output Heat

|

Capacitance

|

Electrode Force

|

Electrode Stroke

|

Steel Belt Width

|

|

WL-C-1K

|

380V

|

1KVA

|

300J

|

3000uF

|

30kg

|

25

|

|

|

WL-C-2K

|

380V

|

2KVA

|

500J

|

4500uF

|

100kg

|

50

|

16-25mm

|

|

WL-C-2.5K

|

380V

|

2.5KVA

|

1000J

|

9000uF

|

100kg

|

50

|

26-30mm

|

|

WL-C-3K

|

380V

|

3KVA

|

1500J

|

14000uF

|

350kg

|

80

|

30-35mm

|

|

WL-C-5K

|

380V

|

5KVA

|

3000J

|

28000uF

|

350kg

|

80mm

|

36-40mm

|

|

WL-C-7K

|

380V

|

7KVA

|

4500J

|

42000uF

|

800kg

|

100mm

|

41-50mm

|

|

WL-C-10K

|

380V

|

10KVA

|

6000J

|

60000uF

|

1000kg

|

100mm

|

|

|

WL-C-12K

|

380V

|

12KVA

|

7000J

|

70000uF

|

1000kg

|

100mm

|

|

|

WL-C-15K

|

380V

|

15KVA

|

8000J

|

80000uF

|

1000kg

|

100mm

|

|

|

WL-C-20K

|

380V

|

20KVA

|

15000J

|

150000uF

|

1500kg

|

100mm

|

|

|

WL-C-25K

|

380V

|

25KVA

|

18000J

|

180000uF

|

2000kg

|

100mm

|

|

|

WL-C-30K

|

380V

|

30KVA

|

20000J

|

200000uF

|

2000kg

|

100mm

|

|

|

WL-C-40K

|

380V

|

40KVA

|

25000J

|

250000uF

|

2000kg

|

100mm

|

|

|

WL-C-50K

|

380V

|

50KVA

|

30000J

|

300000uF

|

2000kg

|

100mm

|

|

|

WL-C-60K

|

380V

|

60KVA

|

35000J

|

350000uF

|

2000kg

|

100mm

|

|

|

WL-C-80K

|

380V

|

80KVA

|

40000J

|

400000uF

|

2000kg

|

100mm

|

|

|

WL-C-100K

|

380V

|

100KVA

|

50000J

|

500000uF

|

2000kg

|

100mm

|

|

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out with the suitable technical proposal based on your samples or drawings.

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out with the suitable technical proposal based on your samples or drawings.

Factory & Certificate

Certifications

We have passed the international certifications such as

CE

certification,

ISO9001

quality management system certification, Alibaba enterprise certification and design patents.

After-sales service & Customer visiting:

1.spot welding machine 1 years warranty except consumable parts;

1.spot welding machine 1 years warranty except consumable parts;

2.Plenty of technical support

online

is available;

3.Quick Back-up Parts Available&Technical Assistance;

4. "Training Video","Instruction Book" ,and "Operation Manual" will be offered;

3.Quick Back-up Parts Available&Technical Assistance;

4. "Training Video","Instruction Book" ,and "Operation Manual" will be offered;

Service Team & feedback

Professional Team

Over the years, Hwashi has cultivated a large number of talented, dedicated and innovative Hwashi people. We have a professional team of experts with rich experience in electrical engineering, mechanical design and welding technology.

Since its establishment

22

years ago

, hwashi technology has traveled to all corners of the world, participated in more than

100

exhibitions

and served more than

8,000

customers

FAQ

Q1: What is the price of your machine?

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary, visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable Technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary, visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Hot Searches