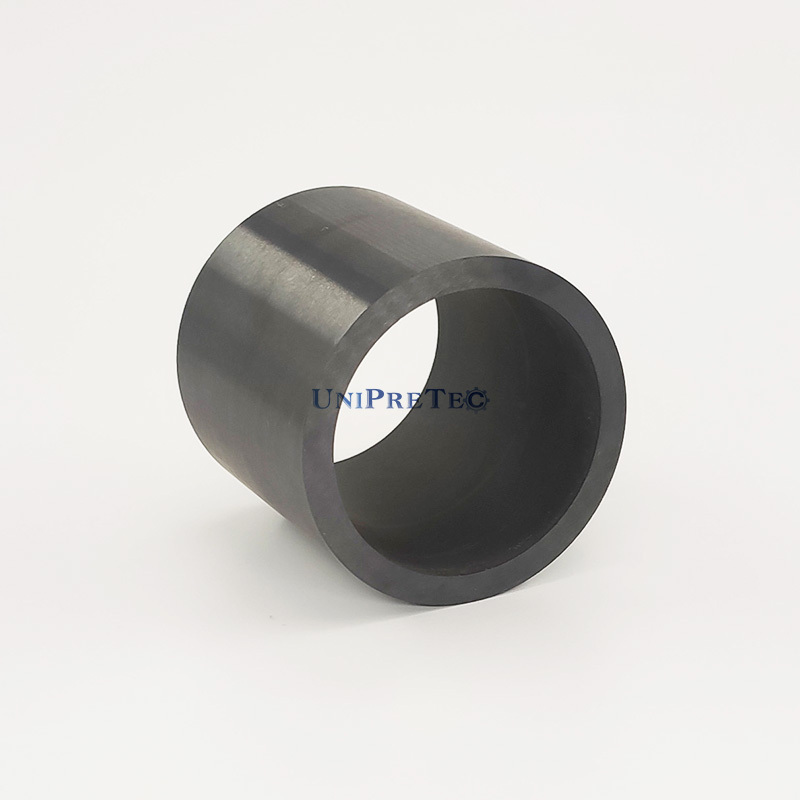

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIPRETEC

-

Processing Service:

-

Polishing

-

Max. Using Temp.:

-

1,200 °C

-

Color:

-

Black

-

Density:

-

3.2 g/cm3

-

Electrical Insulation:

-

Excellent

Quick Details

-

Material:

-

Silicon Nitride

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

Customized

-

Brand Name:

-

UNIPRETEC

-

Processing Service:

-

Polishing

-

Max. Using Temp.:

-

1,200 °C

-

Color:

-

Black

-

Density:

-

3.2 g/cm3

-

Electrical Insulation:

-

Excellent

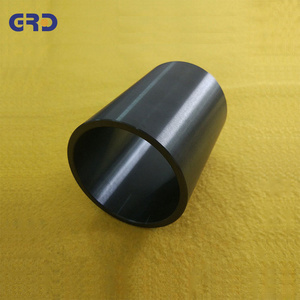

Material Introduction

Silicon Nitride (Si3N4) has the most versatile combination of mechanical, thermal, and electrical properties of any technical ceramic material. It is a high performance technical ceramic that is extremely hard and has exceptional thermal shock and impact resistance. It surpasses most metals high temperature capabilities and has a superior combination of creep and oxidation resistance. Additionally, its low thermal conductivity and high wear resistance make it an excellent material that can withstand the toughest of conditions in the most demanding industrial applications. Silicon Nitride is an excellent choice when high-temperature and high-load abilities are needed.

|

√ low density, low weight

|

√ greatly electrical insulation

|

|

√ non-wetting to non-ferrous metals

|

√ high hardness, high wear resistance

|

|

√ low coefficient of thermal expansion

|

√ outstanding resistance to thermal shock

|

|

√ maximum service temperature up to 1,200 °C

|

√ superior corrosion resistance to molten metals

|

Product Features

Greatly Electrical Insulation

High Hardness

High Corrosion Resistance

Resistant to Thermal Shock

High Use Temperature

Low CTE

High Mechanical Strength

High Use Temperature

Flexible Custom Producing

Applications

Material Properties

|

ITEM

|

UNIT

|

Silicon Nitride | GPSN

|

|

Main Content

|

-

|

Si

3

N

4

>95%

|

|

Color

|

-

|

Black

|

|

Density

|

g/cm

3

|

3.22

|

|

Vickers Hardness

|

Gpa

|

15

|

|

Flexural Strength

|

Mpa

|

580

|

|

Compressive Strength

|

Mpa

|

2,100

|

|

Electrical Resistivity

|

Ω·cm

|

>10

12

|

|

Dielectric Strength

|

KV/mm

|

19

|

|

Dielectric Constant

|

1 MHz

|

9.6

|

|

Thermal Conductivity

|

W/m.K

|

27

|

|

Max. Working Temperature

|

℃ / °F

|

1,200 / 2,200

|

|

Resistance to Thermal Shock

|

△T(℃)

|

750

|

|

Thermal Expansion Coefficient (25 - 1,000 ℃)

|

10

-6

/K

|

3 - 4

|

∆ The above data is offered for reference and comparison only, exact data will vary depending on manufacturing method and part configuration.

Inspection

About Us

"Simple things into very complex, can find new areas; Read the complex phenomenon is very simple, can be found that the new law." - - - - - -Isaac Newton

Hot Searches