- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

Customized

-

Feature:

-

Customized, Good Thermal Stability

-

Place of Origin:

-

SHANDONG

-

Brand Name:

-

SEONTEC

-

Product name:

-

SEONTEC 100% Raw Material PVDF FEP PCTFE PTFE Resin Powder

-

Color:

-

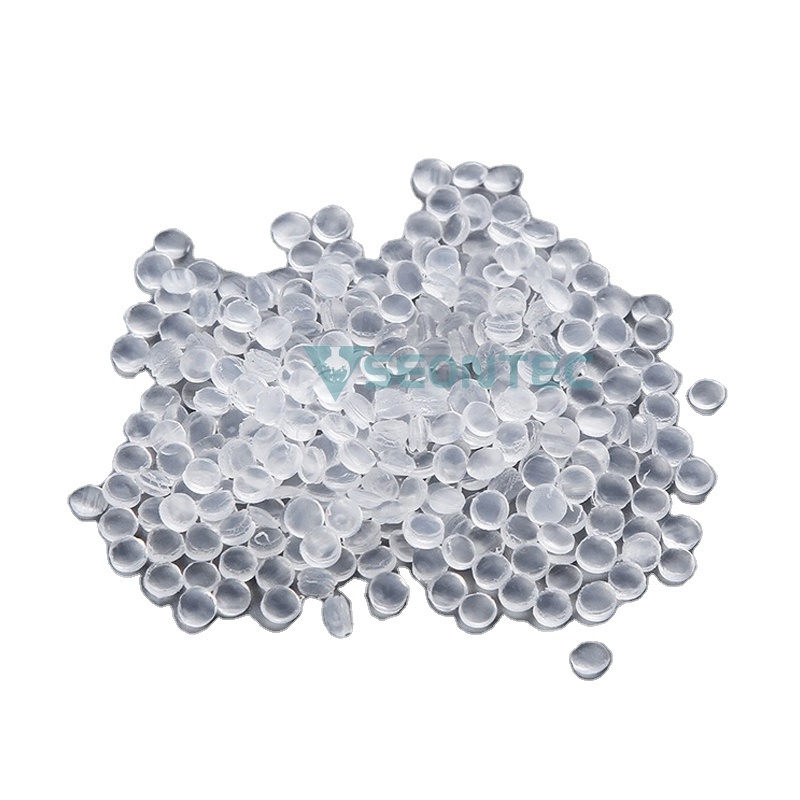

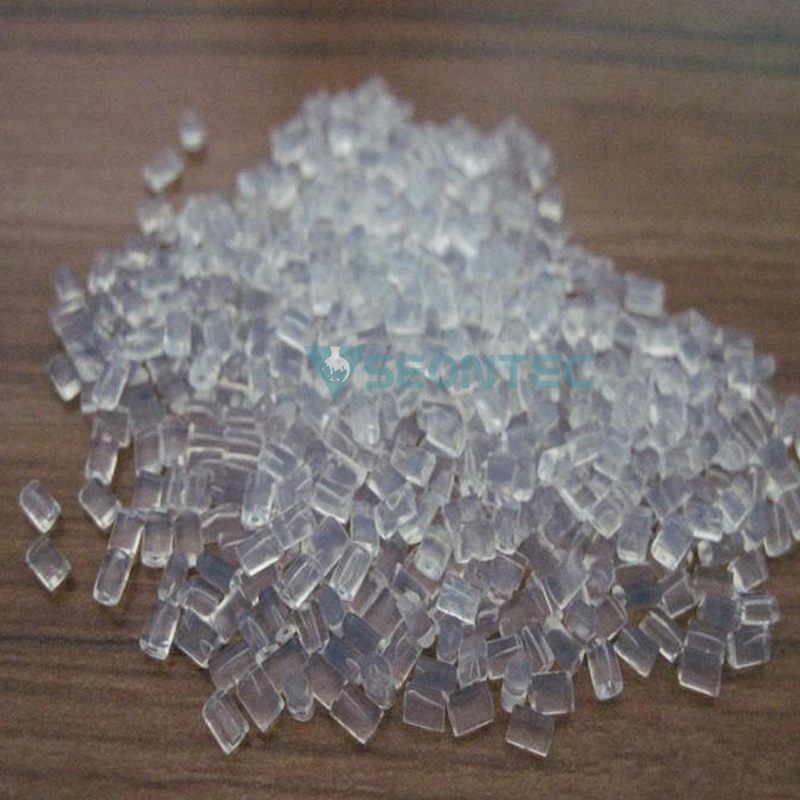

transparent particle

-

Processing Method:

-

Extrusion Molding

-

Melt Index:

-

4.1-8

-

Breaking Strength>:

-

21

-

Elongation>:

-

300

-

Brand:

-

SEONTEC

-

MOQ:

-

100kg

Quick Details

-

color:

-

transparent particle

-

Shape:

-

Powder

-

Application:

-

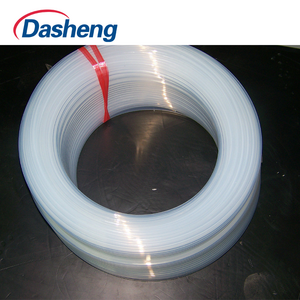

Customized, Wire And Cable,Flim, Tubing

-

Grade:

-

Customized

-

Feature:

-

Customized, Good Thermal Stability

-

Place of Origin:

-

SHANDONG

-

Brand Name:

-

SEONTEC

-

Product name:

-

SEONTEC 100% Raw Material PVDF FEP PCTFE PTFE Resin Powder

-

Color:

-

transparent particle

-

Processing Method:

-

Extrusion Molding

-

Melt Index:

-

4.1-8

-

Breaking Strength>:

-

21

-

Elongation>:

-

300

-

Brand:

-

SEONTEC

-

MOQ:

-

100kg

Products Description

FEP PARTICLE

Polyperfluorinated Ethylene-Propylene Resin (Fep), With Good Thermal Stability, Outstanding Chemical Inertia, Excellent Electrical Insulation And Low Friction Coefficient, Can Be Processed By Thermoplastic Processing Method.

|

Model

|

Melt Index

|

Breaking

Strength>

|

Elongation

>

|

Processing Method

|

Application

|

|

SEM-1

|

0.8-2.0

|

27

|

320

|

Compression Molding, Transfer Molding

|

Lining For Gaskets And Pumps

|

|

SE-1

|

2.1-4.0

|

25

|

300

|

Extrusion Molding

|

Tubing And Thick Jacket Wire And Cable

|

|

SE-2

|

4.1-8

|

21

|

300

|

|

Wire And Cable,Flim, Tubing

|

|

SE-3

|

8.1-12.0

|

21

|

300

|

|

Wire And Cable

|

|

SE-4

|

12.1-20.0

|

18

|

280

|

|

Thin Wire And Cables

|

|

SE-501

|

20.1-36

|

18

|

280

|

High Speed Extrusion Molding

|

High Speed Extrusion Wire And Cables

|

|

SE-511

|

20.1-36

|

19

|

290

|

|

|

|

SE-611

|

36.1-44

|

19

|

290

|

|

|

|

SE-221

|

4.1-8

|

25

|

330

|

Extrusion Molding

|

Stress Crack Resistance Wire,Tubing

|

|

SE-321

|

8.1-12

|

25

|

330

|

|

Wire And Cables Which Require Better Stress Crack Resistance,

Aerospacewire & Cable And Thin-Walled Tube

|

|

SE-521

|

20.1-36

|

22

|

320

|

High Speed Extrusion Molding

|

High Speed Extrusion With Good Stress Crack Resistance

|

|

SE-621

|

36.1-44

|

20

|

320

|

|

|

|

FEP Dispersion Liquid

|

|

|

|

|

|

|||||

|

Model

|

Specific Gravity

|

Solid Content

|

PH

|

Character

|

Application

|

|||||

|

SEDI-1

|

1.37

|

48-52

|

8.5-10.5

|

White Or Yellow Liquid

|

Metallic Coating,Polyimide

Film Coating,Jmpregnation Of Glass Fiber

|

|||||

|

SEDC-1

|

|

|

|

|

|

|||||

Packaging: Commonly Used For 25kg Paper Bucket Or Plastic Bag Packaging, Special Requirements Can Be Customized.

Storage: It Should Be Stored In a Clean, Dry And Cool Environment, Away From Light, Rain, Moisture And Dust.

Details Images

Hot Searches