- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DALINI

-

Model Number:

-

AD485

-

Type:

-

Liquid Glue

-

color:

-

white

-

viscosity:

-

2000-3000mps

-

solid content:

-

48.5%

-

PH:

-

7

Quick Details

-

CAS No.:

-

9009-54-5

-

Other Names:

-

acrylic and PVC glue/adhesive

-

MF:

-

(C11H12O3)n

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DALINI

-

Model Number:

-

AD485

-

Type:

-

Liquid Glue

-

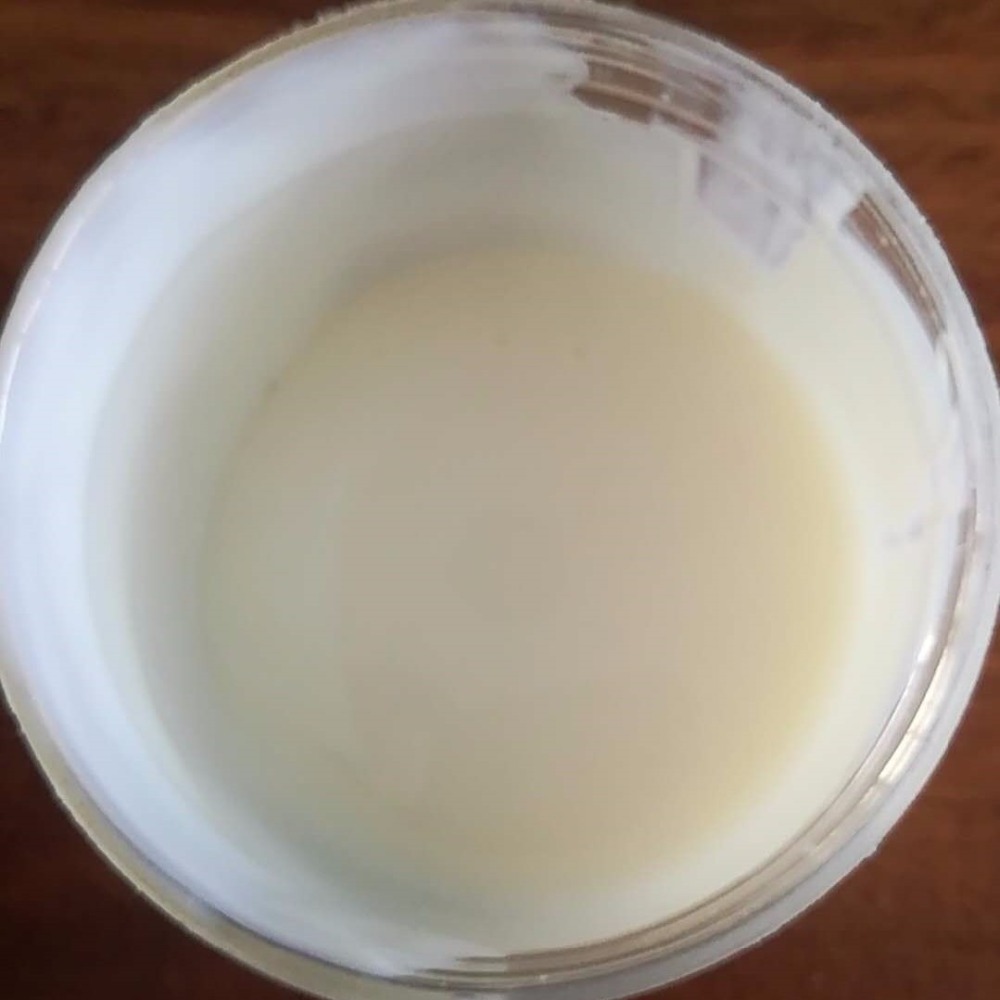

color:

-

white

-

viscosity:

-

2000-3000mps

-

solid content:

-

48.5%

-

PH:

-

7

Technical parameters:

Introduction:

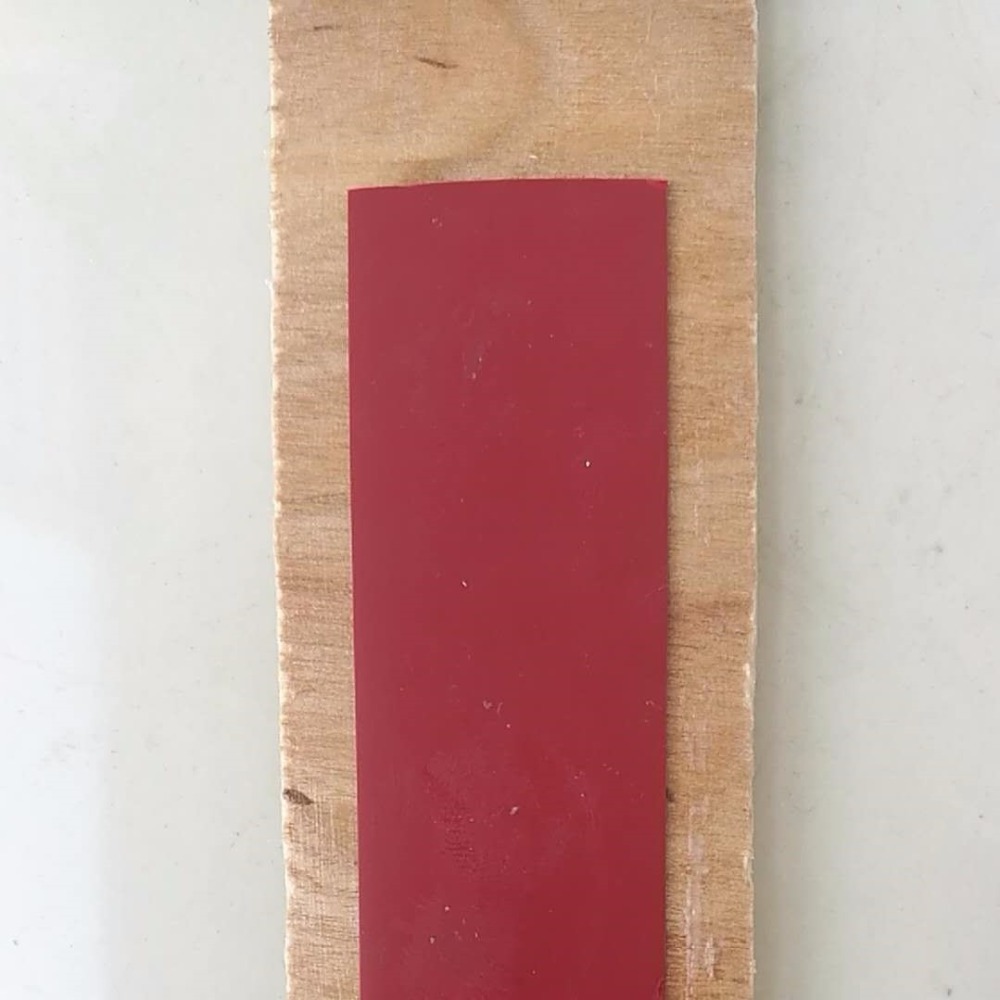

The product is made of modified acrylic emulsion. It is completely water-soluble and environment-friendly without solvent. It is suitable for bonding wood and acrylic board, and wood is bonded with PVC.This product is made from vinyl acetate, acrylic ester and ethylene. It has the advantages of fast adhesion, good initial adhesion, strong adhesion and low temperature film-forming property. It is suitable for gluing on spray cots.After bonding, press for 10 minutes, and the strength is best after 12 hours.

Operation requirements:

(1)The moisture content of the base material is 8 ~ 12%, which requires no crack, oil pollution and resin. The surface of the base material should be smooth and smooth. Using brush or spray, the amount of sizing is adjusted according to different material.

(2) laminating should be pressurized. The contact pressure is generally applied. The pressure is 5 ~ 10kg / cm2. After 24 hours of maintenance, the next working procedure is processed, and the exposure and vibration are avoided during maintenance.

(3) the environmental operation above 5 degrees centigrade, the maintenance time of winter is increased.

The pressure should be maintained for 2~4 hours after pressure relief, and the curing time should be at least 24 hours and winter is longer than summer.

(4)before use, the adhesive must be stirred up and not mixed with other kinds of adhesive. When using, the wood and fiber will be blown away and the dust will remain clean.

Attention:

1. operators should wear good protective tools. The workshops should be well ventilated, and they should be isolated from other workshops.

2. the adhesive time after painting is very important. It is influenced by the temperature, humidity, ventilation, material and so on at that time. It should be grasped flexibly to touch the dry.

3.before using this adhesive, please try it first, so as to avoid errors. If the material change or other special reasons cause the adhesive deviation, please contact with our company in time.

Product service:

Product performance and application data are obtained from long-term practical experience and specific experimental conditions for the user to refer to the product and operation. However, in view of the fact that there are many factors in the actual operation process, such as the surrounding environment, climatic conditions, operation management, quality of sticky materials, pressure time and pressure conditions, the sizing method is not controlled by our company.Sizing and blending ratio will affect the bonding effect. Therefore, it is suggested that the user should do a sample test before using the instructions to ensure the applicability of the product to your specific purpose.