2.

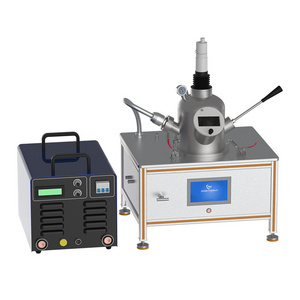

It is a high-performance intelligent heating furnace specially for

university laboratories

, scientific

research institutes

and

enterprises and institutions.

enterprises and institutions.

3.

Suitable for high temperature treatment of materials (carbonization, graphitization, high temperature degreasing, impurity

removal, etc.) under vacuum or gas protection.

removal, etc.) under vacuum or gas protection.