- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Printing Factory

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MOSUN

-

Dimension(L*W*H):

-

6500*2000*2300mm

-

Weight:

-

4500 KG, 4500kg

-

Max Effective Width:

-

1080mm

-

Working Speed:

-

5-40m/min

-

Pressing Temperature:

-

30-120°c

-

Pressure:

-

5-15Mpa

-

Overall power:

-

46kw

-

Overall Dimensions:

-

6500*2000*2300mm

-

Slitting part package woodencase:

-

2200*2200*1700mm

-

Host part package woodencase:

-

2150*1900*2450mm

Quick Details

-

Packaging Type:

-

Wooden

-

Packaging Material:

-

Wood

-

Driven Type:

-

Electric

-

Applicable Industries:

-

Printing Factory

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MOSUN

-

Dimension(L*W*H):

-

6500*2000*2300mm

-

Weight:

-

4500 KG, 4500kg

-

Max Effective Width:

-

1080mm

-

Working Speed:

-

5-40m/min

-

Pressing Temperature:

-

30-120°c

-

Pressure:

-

5-15Mpa

-

Overall power:

-

46kw

-

Overall Dimensions:

-

6500*2000*2300mm

-

Slitting part package woodencase:

-

2200*2200*1700mm

-

Host part package woodencase:

-

2150*1900*2450mm

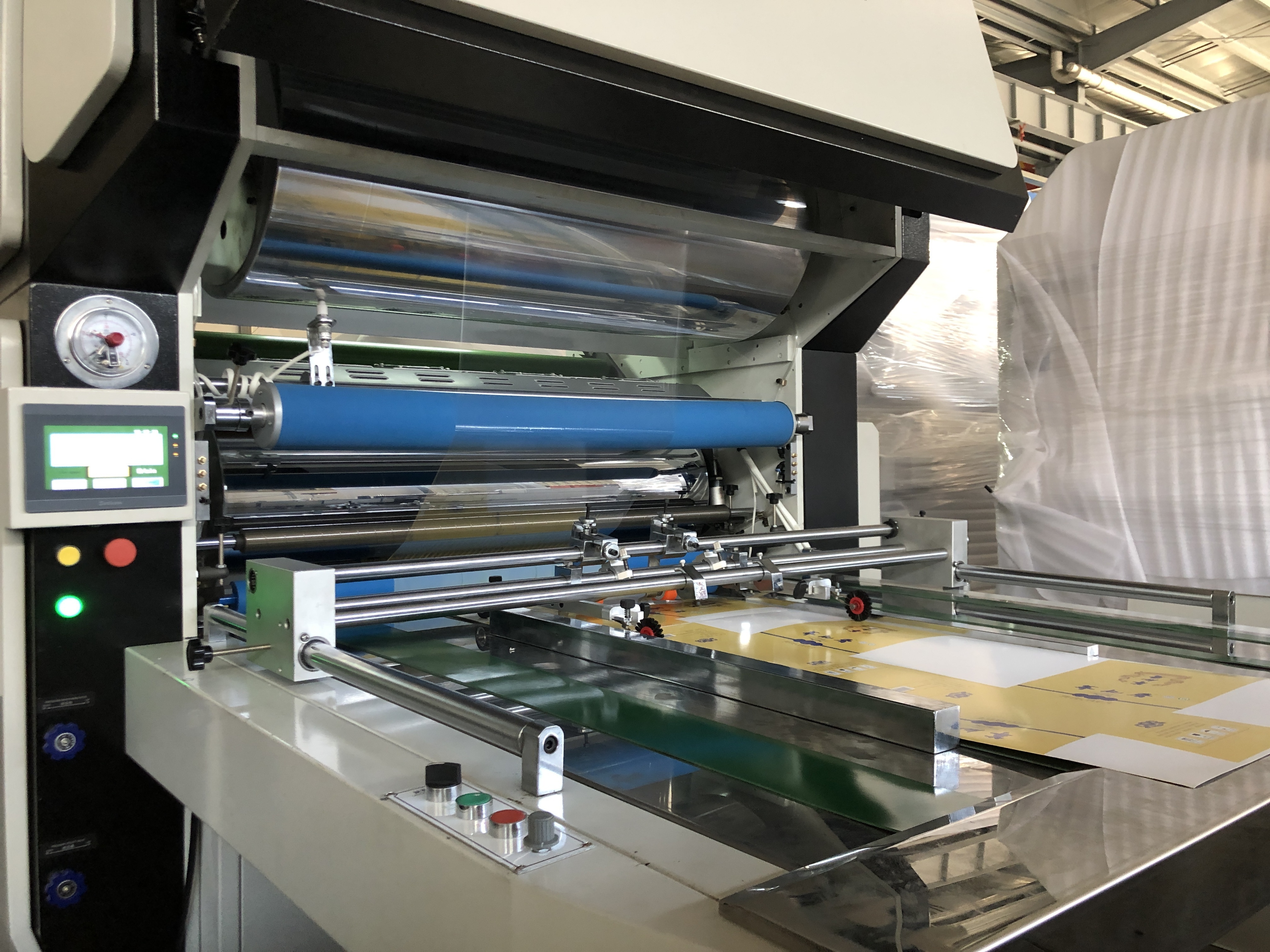

Product Appearance

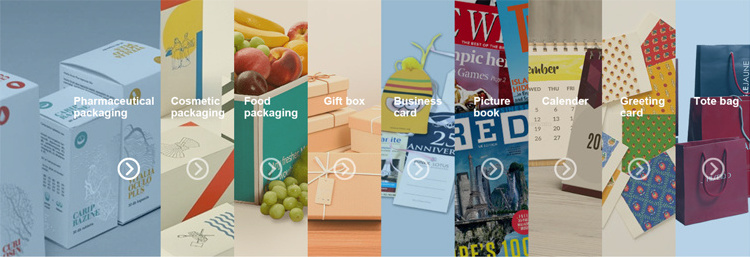

Application

USAGE:

FM-M1080 Vertical High-precision and Mutiduty Laminator is a newly developed product geared to the market demand, which is specially designed for water-based glue. The main unit is applied in cementing, drying and laminating, easy to operate. It can be used for multiple purpose, such as oil-type, water-based, and dry-type lamination.

Widely applicable for laminating in packaging, paper box, books, magazines, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof.

It is a new style film laminating machine.

Products Description

|

Model

|

FM-1080M(with separating machine)

|

|

|

|

Max Paper Width

|

1080mm

|

|

|

|

Working Speed

|

5-40m/min

|

|

|

|

Pressing Temperature

|

30-120°c

|

|

|

|

Paper Thickness

|

100-500g/m²

|

|

|

|

Total Power Required

|

46kw

|

|

|

|

Pressure

|

5-15Mpa

|

|

|

|

Overall Dimensions

|

6500*2000*2300mm

|

|

|

|

Weight

|

4500kg

|

|

|

|

Slitting part package woodencase

|

2200*2200*1700mm

|

|

|

|

Host part package woodencase

|

2150*1900*2450mm

|

|

|

Ralated Products

Details Images

MANUAL FEEDING PART

Manual paper feeding, lap edge device to ensure the accuracy (≤±3mm) of paper feeding, automatic overlap device speed less than 40m/min.

LAMINATING PART

Include three units: gluing unit, drying unit, thermal laminating unit and pressing unit.

Gluing unit: Chromed high brightness gluing rollers to coat evenly and economically. Gluing precision ≤0.008mm.

Drying unit: Use large diameter heating roller (Φ600), temperature is controlled within 80, Strong hot air cycle device and fast drying. Avoid the glue film curl because the high temperature.

Pressing unit: Oil heating roller (Φ320mm), rubber pressure roller (Inside diameter 63mm), the max total pressure is 10T, ensure the good quality with high speed film laminating.

CUTTING PART(FLYING KNIFE)

Using the flying knife device, easy operation. Ensure paper above 105g could be easy cut and break. Cutting machine with thin blade anti-curl device. Could adjustment the thin paper appears the phenomenon of curl when they are cutting. Cutting machine adopts frequency control and host synchronous adjustment function with the laminating machine.

COLLECTING PART

Product packaging

Hot Searches