- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

75 KG

-

Dimension(L*W*H):

-

70*50*65cm

-

Product name:

-

Corn Grinding Mill

-

Application:

-

Food Flour Grinding Mill Machine

-

Function:

-

Multifunction Flour Grinder

-

Final products:

-

Super Fine Flour

-

Capacity:

-

5-1000T/D

-

Material:

-

Cast Iron\carbon Steel\stainless Steel

-

Item:

-

Small-size Corn Milling Machine

-

Used for:

-

Flour Milling Process

-

Advantage:

-

Adjustable Fine Powder Size

-

Color:

-

Customer Demand

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v/380v

-

Power:

-

3kw

-

Weight:

-

75 KG

-

Dimension(L*W*H):

-

70*50*65cm

-

Product name:

-

Corn Grinding Mill

-

Application:

-

Food Flour Grinding Mill Machine

-

Function:

-

Multifunction Flour Grinder

-

Final products:

-

Super Fine Flour

-

Capacity:

-

5-1000T/D

-

Material:

-

Cast Iron\carbon Steel\stainless Steel

-

Item:

-

Small-size Corn Milling Machine

-

Used for:

-

Flour Milling Process

-

Advantage:

-

Adjustable Fine Powder Size

-

Color:

-

Customer Demand

Product Description

Factory price maize wheat rice corn grinding mill for sale in South Africa

The claw-type pulverizer is a small, multi-purpose, new-style pulverizer, which is suitable for grain processing, feed processing, medicinal material processing, seasoning product processing and other chemical product processing in urban and rural units and households. There are two hammer types for users to choose. Equipped with screens of different specifications according to needs, it can process materials with different thicknesses.

The toothed disc grinder adopts a high-speed single-phase motor, which has the characteristics of precise structure, small size, light weight, high efficiency, no dust, clean and hygienic, simple operation, beautiful appearance, power saving and safety, etc. It is more in line with national standards

.

Specification

|

Model

|

Power

|

Capacity

|

machine size

|

|

AKCZ-15

|

1.5kw

|

35-100kg/h

|

540*420*410mm

|

|

AKCZ-19

|

2.2kw

|

150-200kg/h

|

680*680*530mm

|

|

AKCZ-21

|

2.2kw/3kw

|

200-300kg/h

|

700*490*640mm

|

|

AKCZ-23

|

3kw

|

300-400kg/h

|

800*490*850mm

|

|

AKCZ-29

|

4kw/5.5kw

|

400-700kg/h

|

700*900*530mm

|

|

AKCZ-35

|

11kw

|

800-1000kg/h

|

|

Details Images

Thickened and enlarged feed port

Title goes here.

Two inlet ,good quality

Thick bearing housing

Steel grinding wheel for finer grinding

Thickened outlet,

Adopt inclined design, discharge block, high output

Thick base,

Adopting the integrated design of the fuselage, the machine runs smoothly and safely

Different sieves can be choose. 0.3mm 0.2mm

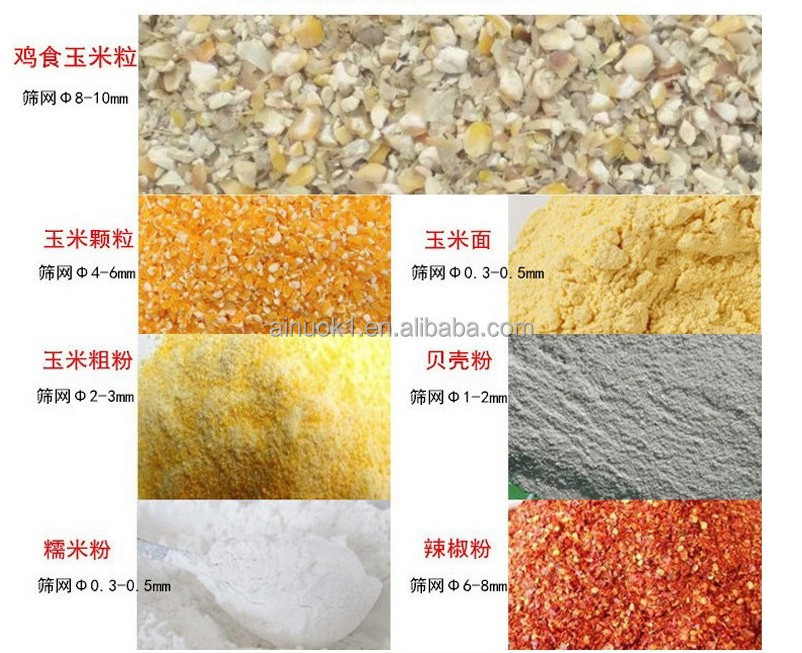

Raw material

Final product

Instructions for use

Instructions for use

1. The pulverizer should be fixed on the cement foundation for long-term operation. If the working place is often changed, the pulverizer and the motor should be installed on the base made of angle iron. If the pulverizer is powered by diesel, the power of the two should match, that is, the power of the diesel engine is slightly greater than the power of the pulverizer, and the power of the two should be made. The pulley grooves are consistent, and the outer end faces of the pulleys are on the same plane.

2. After the pulverizer is installed, check the fastening of the fasteners of each part, and tighten them if they are loose.

3. Check whether the tightness of the belt is appropriate, and whether the motor shaft and the shredder shaft are parallel.

4. Before starting the pulverizer, first turn the rotor by hand to check whether the claws, hammers and rotor are running flexibly and reliably. Whether the lubrication is good.

5. Do not replace the pulley casually, in case the speed is too high to cause the crushing chamber to explode, or the speed is too low to affect the working efficiency.

6. After the crushing table is started, idle for 2 to 3 minutes first, and then feed the material after there is no abnormal phenomenon.

7. Pay attention to the operation of the pulverizer at any time during work, and feed materials evenly to prevent clogging and stuffy cars, and do not run overloaded for a long time. If vibration, noise, overheating of the bearing and body, or material spraying are found, stop the machine immediately for inspection, and continue working after troubleshooting.

8. The crushed materials should be carefully inspected to prevent hard objects such as copper, iron, stones from entering the crushing chamber and causing accidents.

9. The operator should not wear gloves, and should stand on the side of the pulverizer when feeding to prevent the rebounding debris from hurting the face.

Hot Searches