- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HANGJIE

-

Model Number:

-

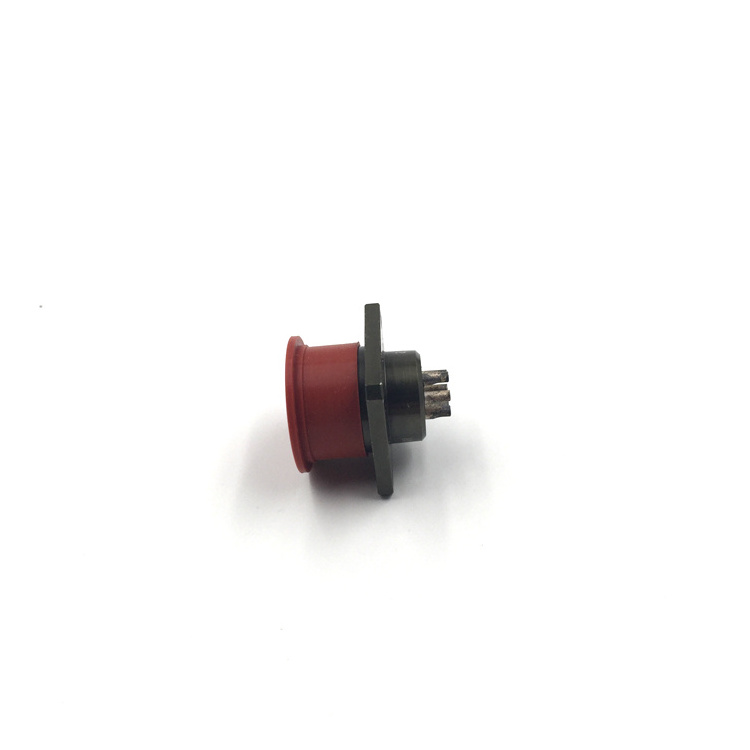

MS3102E14S-6P

-

Product name:

-

MS aviation electrical bayonet amphenol connector

-

Material:

-

High strength aluminum alloy

-

Connector type:

-

6 pin

-

Service Class:

-

Environmental

-

Shell Size:

-

14S

Quick Details

-

Type:

-

ADAPTER

-

Application:

-

Power

-

Gender:

-

Female

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HANGJIE

-

Model Number:

-

MS3102E14S-6P

-

Product name:

-

MS aviation electrical bayonet amphenol connector

-

Material:

-

High strength aluminum alloy

-

Connector type:

-

6 pin

-

Service Class:

-

Environmental

-

Shell Size:

-

14S

MS3102E14S-6P aviation electrical bayonet amphenol connector

Conform to GJB101A standard. With reference to the American MIL-DTL-5015 standards. They are equailvant to JY series, YB series and MS series, MS series. They can cooperate in use with the receptacles which have the same type. This series connectors are quick coupled by bayonets. Their contacts are soldered.

HOW TO ORDER

| Identification Code MS | 3106 | A | 18 | 10 | P | Y | |||||

|

Shell NO.

3100 = Wall mounting receptacle

|

|||||||||||

|

Service Class

A = Solid shell, solder contacts and non-pressurized

|

|||||||||||

| Shell Size 10SL, 12S, 12, 14S, 14, 16S, 16, 18, 20, 22, 24, 28, 32, 36 | |||||||||||

|

Contact layout (See below)

|

|||||||||||

|

Contact Type

P = Pin

|

|||||||||||

| Alternate positioning NO Mark-N key, (W)-W key, (X)-X key, (Y)-Y key, (Z)-Z key | |||||||||||

Specifications

Shell: Aluminum alloy; Olive drab cadmium or zinc plating

Insulator: Synthetic rubber

Contact: Copper alloy; Sliver plating

Gasket & Grommet: Synthetic rubber

B. Electrical specifications

Operating voltage & Test voltage,

| Service class | Operating voltage | Test voltage | Air Spacing | Cree page | |

| DC (V) | AC (V) | AC (V) | Nominal (Inches) | Nominal (Inches) | |

| Inst. | 250 | 200 | 1000 | - | 1/16 |

| A | 700 | 500 | 2000 | 1/16 | 1/8 |

| D | 1250 | 900 | 2800 | 1/8 | 3/16 |

| E | 1750 | 1250 | 3500 | 3/16 | 1/4 |

| B | 2450 | 1750 | 4500 | 1/4 | 5/16 |

| C | 4200 | 3000 | 7000 | 5/16 | 1 |

Rated current (+20 o C ),

|

Contact size |

Contact resistance (mΩ) |

Test current (A) |

Potential drop (mV) |

|

16 |

16 |

13 |

49 |

|

12 |

3 |

23 |

42 |

|

8 |

1 |

46 |

26 |

|

4 |

0.5 |

80 |

23 |

|

0 |

0.2 |

150 |

21 |

Insulator resistance: +25 o C ≥ 5000MΩ

- C. Mechanical specifications

- Operating temperature: -55 o C ~ +125 o C

Sealing: Under water (6 feet in water): 48 hours per MIL-DTL-5015, 4.6.19. Meet 20 days extreme humidity testing per.

|

Contact size |

Outside dia. of insulation |

|||

|

Min. |

Max. |

|||

|

inches |

mm |

inches |

mm |

|

|

16 |

0.064 |

1.63 |

0.130 |

3.30 |

|

12 |

0.114 |

2.90 |

0.170 |

4.32 |

|

8 |

0.164 |

4.17 |

0.255 |

6.48 |

|

4 |

0.275 |

6.98 |

0.370 |

9.40 |

|

0 |

0.415 |

10.54 |

0.550 |

13.97 |

Durability: ≥ 100 cycles

Salt spray: MIL-STD-1344 method 1001, condition B, ≥ 48 hours (Cadmium plating)

Heat: at +125 o C, 60 hours; at +85 o C, 1000 hours

Chemical resistance: in Hydraulic fluid or lubricating oil, 20 hours

Vibration: 10 ~ 2000Hz, acceleration: 10 g’s

Shock: acceleration: 50g

Contact retention & Separation force

|

Contact size |

Retention |

Separation force min. |

||

|

N |

Lbs. |

N |

Lbs. |

|

|

16 |

44 |

10 |

1 |

0.25 |

|

12 |

67 |

15 |

2 |

0.50 |

|

8 |

89 |

20 |

3 |

0.75 |

|

4 |

89 |

20 |

4 |

1.00 |

|

0 |

111 |

25 |

9 |

2.00 |