1. Backgauge control.

2. Control for general AC motor

3. Intelligent positioning

4. Double programmable digital output, stock counter

5. Program memory of up to 40 programs

6. Up to 25 steps per programs

7. One side positioning, Retract function

8. One key backup/restore of parameters

9. mm/inch, Chinese/English

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

10 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BLMA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380/220/415/440/600V

-

Dimension(L*W*H):

-

3900X1600X1750 mm

-

Year:

-

2022

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1.5

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

10 - 600 mm

-

Throat Depth (mm):

-

100 mm

-

Brand Name:

-

BLMA

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

380/220/415/440/600V

-

Dimension(L*W*H):

-

3900X1600X1750 mm

-

Year:

-

2022

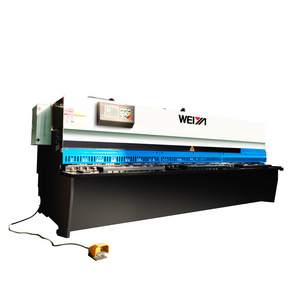

QC12Y/K Series Swing Beam Hydraulic Shearing Machine

BLMA swing beam shearing machine adopts steel plate welding structure, which eliminates stress during vibration, and has good rigidity and stability. It has segmented cutting function, light alignment function, motorized back gauge, digital display.

E21S Control System

Optional System

ES10 CNC Control System

7-inch TFT real color touch screen

Menu programming interface

Programmable cutting function

Automatic calculation of cutting length

Automatic correction of backgauge

Backgauge is controlled by servo motor

Automatically calculate blade clearance

Automatically calculate cutting angle

Support multi languages.

DAC310 (DELEM) CNC Control System

Bright LCD 128 x 64 display

Backgauge control

Gap control

Stroke length limitation

Actual and Programmed position visualization

Stock counter

Programmable up to 100 steps

Panel-based housing

Servo control / inverter / 2-speed AC control

Motor and Pump

stable work, long work life.

Hydraulic System

Pressing Mechanism

with plate pressing mechanism.

The pressing head presses down to compress the plate when cutting plate.

Steel Ball Transmission Structure

BLMA QC12K shearing machine is equipped with steel ball transmission structure,

which can saves the operator's effort in feeding material and increase the efficiency.

Ball Screw and Linear Guider

Main Electrics

Open door power off switch

worker opens the door electric cabinet

Guardrail

blade clearance adjustment

Adjust the cutting blade gap by motor according to the thickness of plate, which can get better cutting performace.

Laser Light Alignment (optional)

Pneumatic Backguage (optional)

|

Type

|

Cutting thickness (mm)

|

cutting length

(mm)

|

Throat Depth

(mm)

|

Back-gauge range

(mm)

|

Main Power (KW)

|

Dimension(mm)

|

|

4x2500

|

4

|

2500

|

100

|

20-600

|

5.5

|

3200x1600x1600

|

|

4x3200

|

4

|

3200

|

100

|

20-600

|

5.5

|

3900x1600x1600

|

|

6x2500

|

6

|

2500

|

100

|

20-600

|

7.5

|

3200x1650x1800

|

|

6x3200

|

6

|

3200

|

100

|

20-600

|

7.5

|

3900x1650x1800

|

|

6x4000

|

6

|

4000

|

100

|

20-600

|

7.5

|

4700x1650x1800

|

|

8x2500

|

8

|

2500

|

100

|

20-600

|

7.5

|

3200x1700x1850

|

|

8x3200

|

8

|

3200

|

100

|

20-600

|

7.5

|

3900x1700x1850

|

|

10x2500

|

10

|

2500

|

120

|

20-600

|

11

|

3200x1850x1900

|

|

10x3200

|

10

|

3200

|

120

|

20-600

|

11

|

3900x1850x1900

|

|

12x3200

|

12

|

3200

|

120

|

20-600

|

18.5

|

3900x2050x2150

|

|

16x3200

|

16

|

3200

|

120

|

20-600

|

18.5

|

3900x2150x2250

|

|

20x3200

|

20

|

3200

|

120

|

20-600

|

22

|

3900x2250x2350

|

We can supply series models, please contact us.

Hot Searches