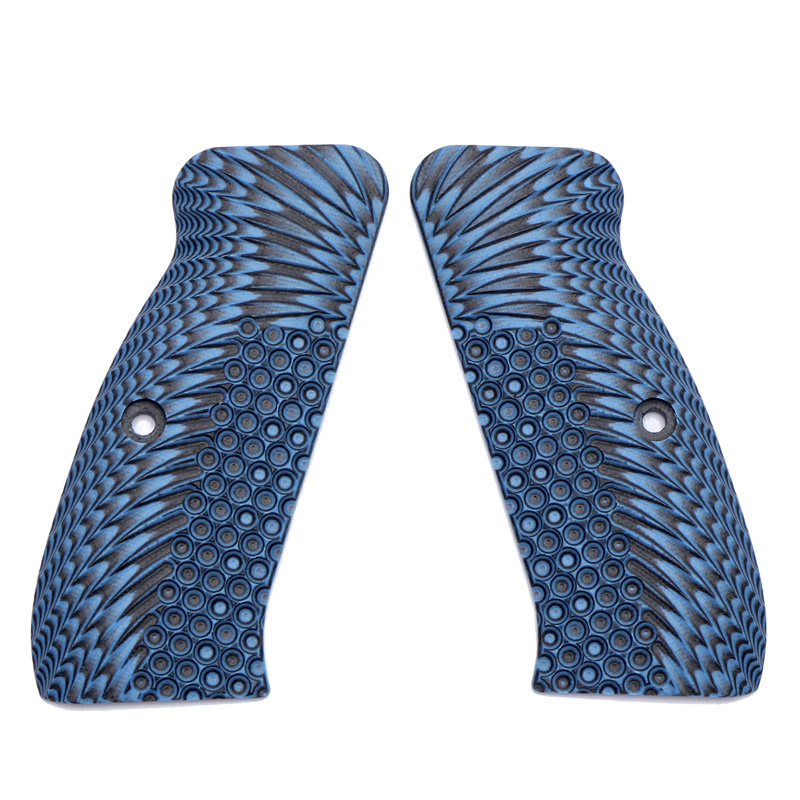

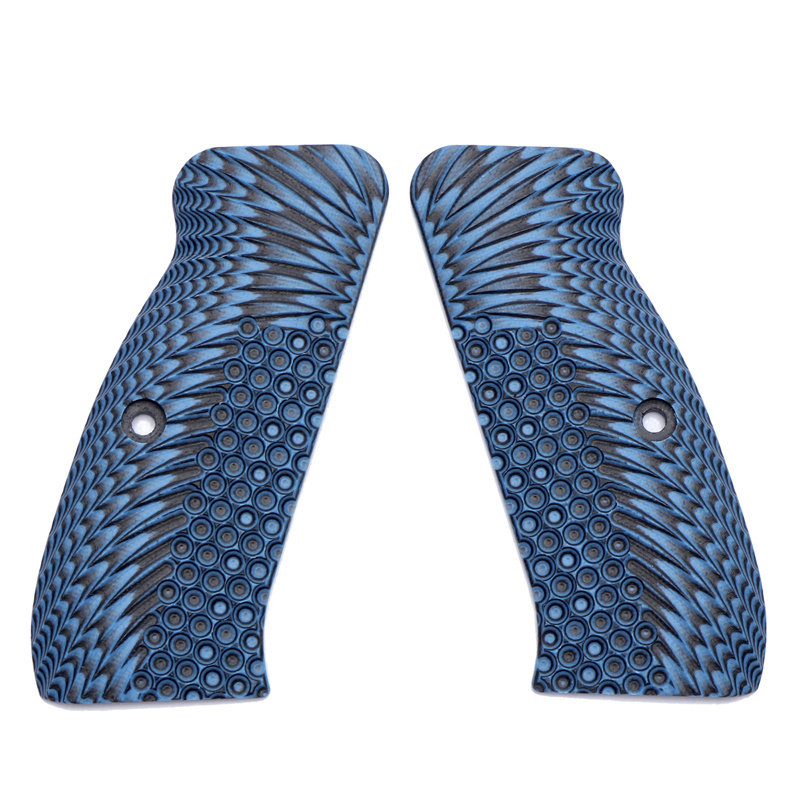

there are more than 10 different colors and textures for optional ,

we can also make custom colors and textures with small MOQ, please contact me to learn more!

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

H6-A

-

size:

-

Full size

-

Product name:

-

G10 grips

-

Material:

-

G10 - fiberglass and epoxy resin

-

Feature:

-

Anti-slip

-

Texture:

-

Aggressive OPS

-

Frame:

-

Full size

-

Certification:

-

S GS

Quick Details

-

Type:

-

Scope Mounts & Accessories

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

H6-A

-

size:

-

Full size

-

Product name:

-

G10 grips

-

Material:

-

G10 - fiberglass and epoxy resin

-

Feature:

-

Anti-slip

-

Texture:

-

Aggressive OPS

-

Frame:

-

Full size

-

Certification:

-

S GS

Product Description

G-10 materials Grips

We can make all kinds of G10 fiberglass and epoxy resin grips for all tactical gears,

Specifications:

|

Product Name

|

Custom High Precision CNC Machined Anti-Slip G10 Grips

|

|

|

|

Material

|

G10 - fiberglass and epoxy resin

|

|

|

|

Usage

|

For Knife/Tactical

|

|

|

|

Color

|

More than 10 different colors in stock and custom colors

|

|

|

|

Packing

|

Bubble Bags/Blister box

|

|

|

|

MOQ

|

2 pairs

|

|

|

|

Sample

|

Samples are always available

|

|

|

|

Texture

|

OPS, Sunburst, Starburst, Double Checkered, Bogies, Skull(Punisher)... etc, and Custom

|

|

|

|

Processing method

|

High precision CNC machined

|

|

|

Usage

Application:

G10 materials

grips are used for

Knife handles,

Tactical grips,

Tactical grips,

etc

Related Products

H1 - Full size grips with standard bottom

H2 - Full size grips with round bottom

H3 - Full size grips with Magwell bottom

Packing&Shipping

We can send all products by Air/Sea, DHL/UPS/FEDEX/ARAMEX....etc, with best discount, pls contact me to get best shipping cost.

Company Introduction

Always Ready For Supplying The Best Solution For Your Various Applications

* We always adhere to the business philosophy of quality first, the supremacy of credibility, integrity and truth-remaining,

win-win cooperation , and unifying scientific research, developing, producing all kinds of insulation material products. Our

company have strong technical strength, and have a experienced talents team in research and development, to assure we produce the products with advanced quality.

* Our epoxy fiberglass products mainly used in high-end insulation parts processing, FPC (flexible printed circuit-board)

reinforcement sheet, the battery cover, planetary wheel, transformer insulation baffle,electronic insulation parts, insulation

gasket, insulation washer, electrical equipment such as motors, generators, transformers and high voltage switch, precision test fixture jig, ICT test fixture, FCT fixture, various water sports equipment like surfing fins, hydrofoil wings, Knife handle materials, Tactical grips, it can also be used in damp environment condition in the transformer-oil. And the carbon fiber products has been applied in aviation, automobile decoration, precision mechanical parts, high-end sports equipment and surface decoration,aircraft models, car models, and many other fields.

* Our next development direction: Customer as the center, market orientation and industrial upgrading as the direction of

development, developing new products with high added value and high performance.

FAQ

1. What's G-10?

Re: G10 is a composite material, or to put it more accurately is a formula for a composite material that has

specific material characteristics. Specifically, it's pretty strong, doesn't absorb moisture, is a very decent electrical

insulator and resists chemicals pretty well. In other words, pretty tough stuff.

specific material characteristics. Specifically, it's pretty strong, doesn't absorb moisture, is a very decent electrical

insulator and resists chemicals pretty well. In other words, pretty tough stuff.

It's basically fiberglass, with layers of glass cloth that sets in an epoxy resin. The composite is baked and compressed, producing a hardened composite material.

2. Are you manufacturer?

Re: Yes, we are 100% Original factory of all kinds of G10 products.

Re: Yes, we are 100% Original factory of all kinds of G10 products.

We can make custom grips for

knives

and other gears.

3. What's the lead time?

Re: Normally, we can finish 1000 pairs in 15 days, pls contact me to learn more.

4. Do you support customization?

Re: Yes, we can make custom grips for you, FREE design, LOW MOQ.

3. What's the lead time?

Re: Normally, we can finish 1000 pairs in 15 days, pls contact me to learn more.

4. Do you support customization?

Re: Yes, we can make custom grips for you, FREE design, LOW MOQ.

Hot Searches