- Product Details

- {{item.text}}

Quick Details

-

Epoxy color:

-

White

-

Hardener color:

-

Black

-

Finish color:

-

Gray

-

Mix ratio:

-

1:1 (by volume)

-

Shelf life:

-

24 months

-

Working time:

-

5 mins

-

Full curing:

-

60 mins

-

Hardness Shore D:

-

82

-

Compressive strength:

-

7295

-

Shrinkage:

-

<1%

Quick Details

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

FASTFIX

-

Model Number:

-

FX-CE

-

Epoxy color:

-

White

-

Hardener color:

-

Black

-

Finish color:

-

Gray

-

Mix ratio:

-

1:1 (by volume)

-

Shelf life:

-

24 months

-

Working time:

-

5 mins

-

Full curing:

-

60 mins

-

Hardness Shore D:

-

82

-

Compressive strength:

-

7295

-

Shrinkage:

-

<1%

Production Name:

Epoxy ceramic bead

Product Code:

FX-CE

Product Description:

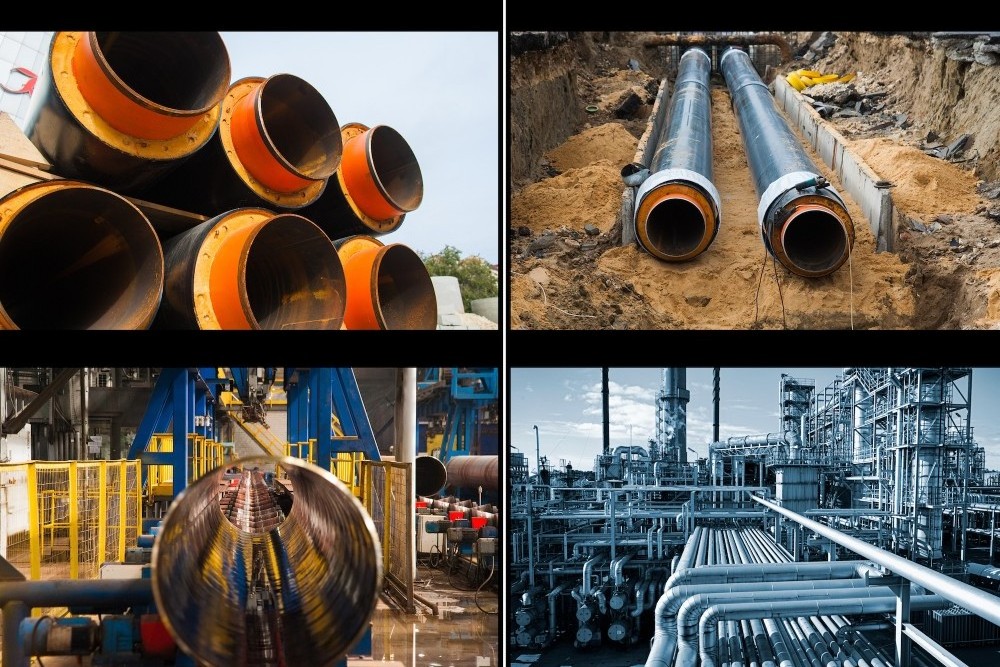

Bead Wearing Compound combines the abrasion resistant properties of both large and small ceramic beads and silicon carbide in a trowelable epoxy that protects against the damage of hard sliding abrasion under typical dry service temperatures of pump liners and impellers, chute linings and hoppers, cyclone and separator bodies, fan blades and housing, scrubers, dust collectors and exhausters, large pump suction area.

Advantages:

1. Low contraction after curing.

2. Excellent wear resistance, impact resistance.

Usage:

1. On vertical or overhead areas, it is recommended to tack expanded metal mesh to substrate before application of Combo Bead Wearing Compound.

2. Clean, dry and abrade application surface. The more thorough the degree of surface preparation the better the performance of the application. If possible, it is recommended that the surface be grit blasted to a Near White Metal (SSPC-SP10/NACE No. 2) Standard. For less severe applications roughening the surface with hand tools is suitable.

3. Solvent cleaning with a residue-free solvent is recommended as the final step to aid in adhesion.

How to Use:

1. Clean the equipment before use

2. To blend the hardener into main agent according to the provisions of the ratio, and using a mixer to mix evenly. In the meantime, using a scraper or other tools to remove the unmixed base or hardener carefully.

3. In the middle of mixing, DO NOT mix with any other water.

4. After mixing, soak the hands, apply a small amount of epoxy coating material to coat on the surface, and evenly smear the coating (Wetting manual method).

5. Whether steel, aluminum, stainless steel and concrete, must have the appropriate surface roughness.

6. All substrates should be clean and free from dirt and dirt that may adversely affect adhesion.

7. The construction tools should be washed immediately after using.

Where to Use:

Shipping:

By sea/ air/ courier. (FOB Kaohsiung)

Courier includes DHL, FedEx, TNT, EMS, etc.