- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

puhua

-

Voltage:

-

customizable

-

Power:

-

customizable

-

Dimension(L*W*H):

-

customizable

-

Weight (KG):

-

8000

-

Function:

-

sheet Metal Surface painting

-

Machine:

-

Steel Surface Treatment Machine

-

Color:

-

Custermized

-

Blast wheel:

-

puhua

-

Keywords:

-

Overhead Conveyor System painting line

-

Certification:

-

ce

-

Name:

-

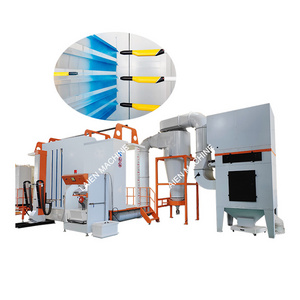

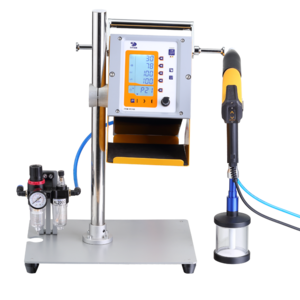

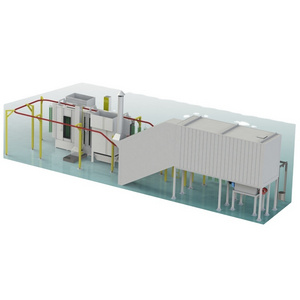

Automatic powder coating Steel structure spray painting system

Quick Details

-

Machine Type:

-

Overhead Conveyor System painting line, Pre-treatment Equipment, Conveying Equipment, Coating Equipment, Sandblasting Machine

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

puhua

-

Voltage:

-

customizable

-

Power:

-

customizable

-

Dimension(L*W*H):

-

customizable

-

Weight (KG):

-

8000

-

Function:

-

sheet Metal Surface painting

-

Machine:

-

Steel Surface Treatment Machine

-

Color:

-

Custermized

-

Blast wheel:

-

puhua

-

Keywords:

-

Overhead Conveyor System painting line

-

Certification:

-

ce

-

Name:

-

Automatic powder coating Steel structure spray painting system

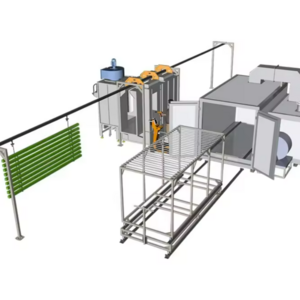

Conveyor Type Hanging Chain painting line

Advantages:

1. Wide application, Easy to install and use.

2. Customized, Meet your needs.

3. Good stability, L ow failure rate (technical maturity, technical precipitation, skilled workers).

4. Exquisite appearance (mature craft).

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

7. Factory direct selling with competitive price.

8. Over 10 years' production experience.

9. Professional design team to serve you.

10. Mainly electrical control system adoptsinternational brand.

11. CE certificate assure you our quality.

Strong point of this series shot blasting machine:

|

1 |

Improve the corrosion resisting ability of machinery products and metal materials. |

|

2 |

Improve bonding strength of steel surfaces and coatings. |

|

3 |

Increase the anti-fatigue capability of metal products and extend its life. |

|

4 |

Optimize the craftwork state of steel surface. |

|

5 |

Greatly enhance the efficiency of cleaning. |

|

6 |

Reduce the labor intensity of cleaning works. |

|

7 |

Reduce the environment pollution. |

|

Type

|

Q383/Q483

|

Q385/Q485

|

Q4810

|

|

Cleaning workpieces size(mm)

|

φ800*1200

|

φ1000*1500

|

φ1000*2500

|

|

Number of work position

|

2

|

2

|

2

|

|

Quantity of impeller head

|

4

|

4

|

6

|

|

Impeller head volume(kg/min)

|

4*250

|

4*250

|

6*250

|

|

Impeller head power(kw)

|

4*15

|

4*15

|

6*15

|

|

Max hangering weight(kg)

|

300

|

500

|

1000

|

|

Productivity hanger(/h)

|

30~60

|

30~60

|

40~60

|

|

Size of the cleaning room(mm)

|

7680*2000*2900

|

7680*2000*2900

|

7680*2000*3800

|

|

Total power(kw)

|

73.15

|

73.15

|

114.72

|