- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KAIDONG

-

Voltage:

-

380/415/440/220V, 380/415/440V

-

Dimension(L*W*H):

-

1800*1800*1500mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

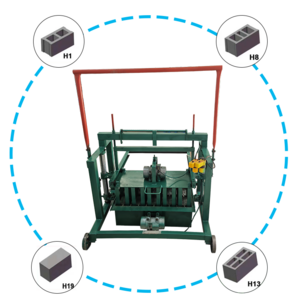

QTM4-30A Moving block machine

-

Moulding period:

-

30-40S

-

Mixer model:

-

JQ350/JQ500

-

Host machine power:

-

6.7KW

-

Dimension of host machine:

-

1800*1700*1700mm

-

Color:

-

Customized

-

Block Type:

-

Hollow, Paver, Soild

-

Raw material:

-

Sand Cement

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

720-12960pcs/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KAIDONG

-

Voltage:

-

380/415/440/220V, 380/415/440V

-

Dimension(L*W*H):

-

1800*1800*1500mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

QTM4-30A Moving block machine

-

Moulding period:

-

30-40S

-

Mixer model:

-

JQ350/JQ500

-

Host machine power:

-

6.7KW

-

Dimension of host machine:

-

1800*1700*1700mm

-

Color:

-

Customized

-

Block Type:

-

Hollow, Paver, Soild

-

Raw material:

-

Sand Cement

-

After-sales Service Provided:

-

Field installation, commissioning and training

QTM4-30A Movable Concrete Block Making Machine

Low investment: high efficiency: this machine have several function features, such as low price,reliable performance, easy to operated, stable, more efficient, high output, low power consumption.the brick it produced have high density, high strength, accurate dimensional, good appearance,so it can reduce the customer's investment and production costs and give fast and large benefit.

Mainframe

Name: QTM4-30A Movable Concrete Block Making Machine

Brand: KAIDONG

Original: China

The production capacity depends on this forming machine and it is also the essential part of the whole production line. You can change moulds on this parts to make different shapes of blocks, bricks, pavers and curbstones.

• The electricity motor for host machine we use Germany Siemens motor, for other parts, we use CE motor.

• About the switches, we will use France Schneider or China CHNT.

• Rakes in several rows make sure raw materials fed well-distributed.

• Hydraulic components we use Taiwan JiuGang famous brands.

• The demolding synchronizer avoids the damage to concrete products.

• The vibration system contain two part, one is up-mould vibration box, it is electricity motor to supply the power for up-mould vibration box. And the down mould, there is one big vibration. When the scatter material work is finished, the hydraulic power with the two vibration power will assure the good quality for product.

•

Heavy duty machine structure and wear resistant moulds

are

processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times.

Greatly improves the using lifetime of the machine by 50%.

• Use Frequency Conversional Control Technology, which controls the block making:

1. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products

from transfiguration; increases the production rate by improving the vibrating efficiency;

2. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

3. Power saving: 30%.

• Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

1.Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

2.Guarantee production stability.

•

360° Multi-Shaft Rotating and Compulsory Feeding:

1. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed;

2. This uniform feeding is applicable for different kinds of raw materials and moulds.