- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

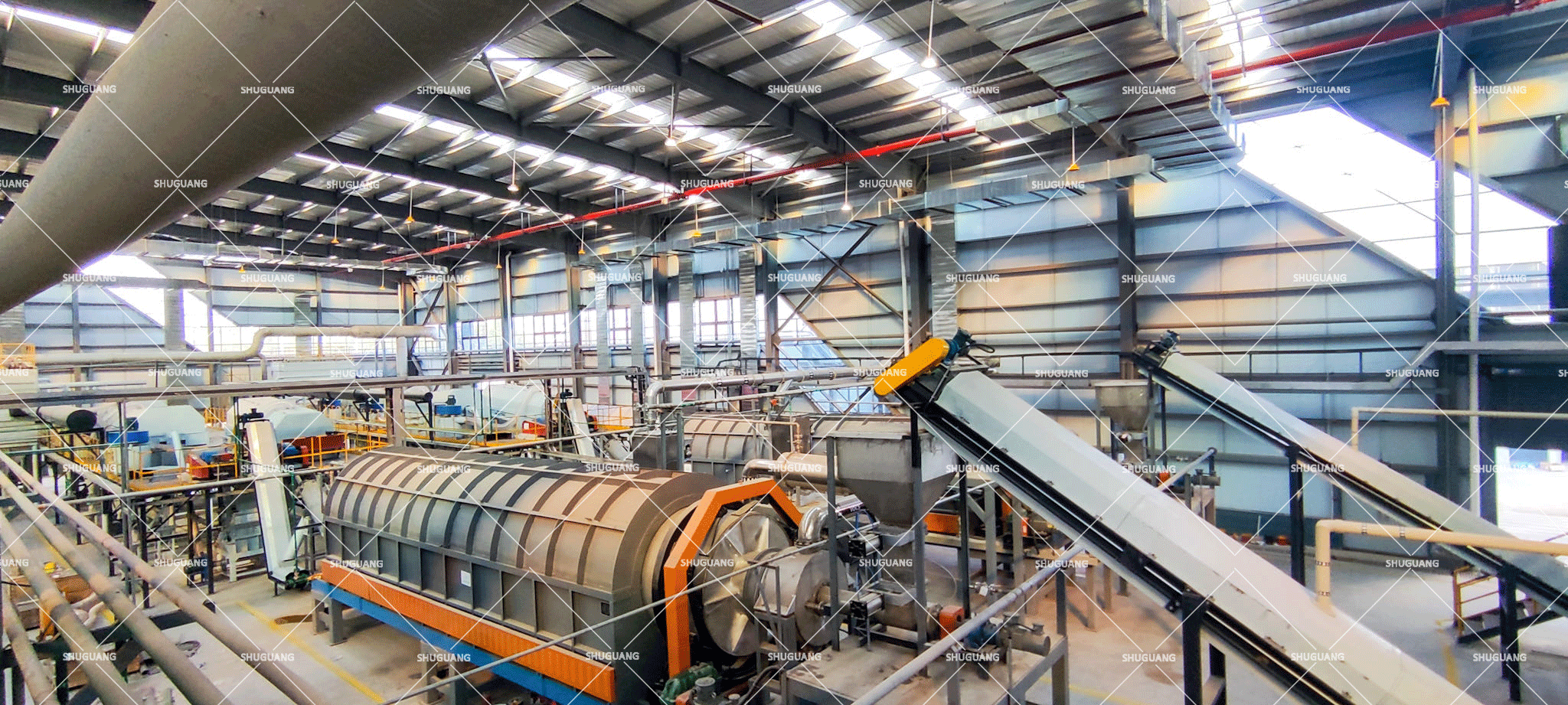

Lithium Battery Recycling Machine

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

14700 kg

-

Name:

-

Lithium Battery Recycling Machine Plant

-

Application:

-

Recycling waste lithium batteries

-

Function:

-

Get economic benefit by recycle waste lithium battery.

-

Technology:

-

Crushing, vibrating screening and air separation

-

Raw material:

-

Hard package battery, soft package battery, Cylindrical battery

-

Final product:

-

Graphite powder, Cobalt acid lithium,Aluminum and copper

-

Advantage:

-

Green and low carbon,energy saving and no secondary

-

Feature:

-

Refuse Collector, Fully Automatic

-

Business Type:

-

Manufacture(OEM and ODM)

-

Installation:

-

YES

Quick Details

-

Production Capacity:

-

200kg/h-1000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHUGUANG

-

Model Number:

-

Lithium Battery Recycling Machine

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

14700 kg

-

Name:

-

Lithium Battery Recycling Machine Plant

-

Application:

-

Recycling waste lithium batteries

-

Function:

-

Get economic benefit by recycle waste lithium battery.

-

Technology:

-

Crushing, vibrating screening and air separation

-

Raw material:

-

Hard package battery, soft package battery, Cylindrical battery

-

Final product:

-

Graphite powder, Cobalt acid lithium,Aluminum and copper

-

Advantage:

-

Green and low carbon,energy saving and no secondary

-

Feature:

-

Refuse Collector, Fully Automatic

-

Business Type:

-

Manufacture(OEM and ODM)

-

Installation:

-

YES

Product Description

PRODUCT APPLICATION BACKGROND

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte and diaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides of an aluminum foil current collector through PVDF which plays a bonding role;The negative electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector. At present, the research on the recycling of wastelithium batteries is mainly focused on the recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries.

Related Products

Hot Searches