- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

1500-6000kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Screening\separation\sorting\sieving

-

Inclination:

-

2-2.5 degree

-

Motor:

-

Vertical Vibrating Motor

-

Capacity:

-

1-25ton/hour

-

Material:

-

Carbon Steel/screw-thread steel

-

Mesh size:

-

3-20mm

-

Cleaning system:

-

Hitting cleaning device

-

Screening material:

-

Small Medium Granule Material

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SHUNXIN

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Standard

-

Weight:

-

1500-6000kg

-

Warranty:

-

12 Months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Screening\separation\sorting\sieving

-

Inclination:

-

2-2.5 degree

-

Motor:

-

Vertical Vibrating Motor

-

Capacity:

-

1-25ton/hour

-

Material:

-

Carbon Steel/screw-thread steel

-

Mesh size:

-

3-20mm

-

Cleaning system:

-

Hitting cleaning device

-

Screening material:

-

Small Medium Granule Material

-

Certification:

-

ISO9001

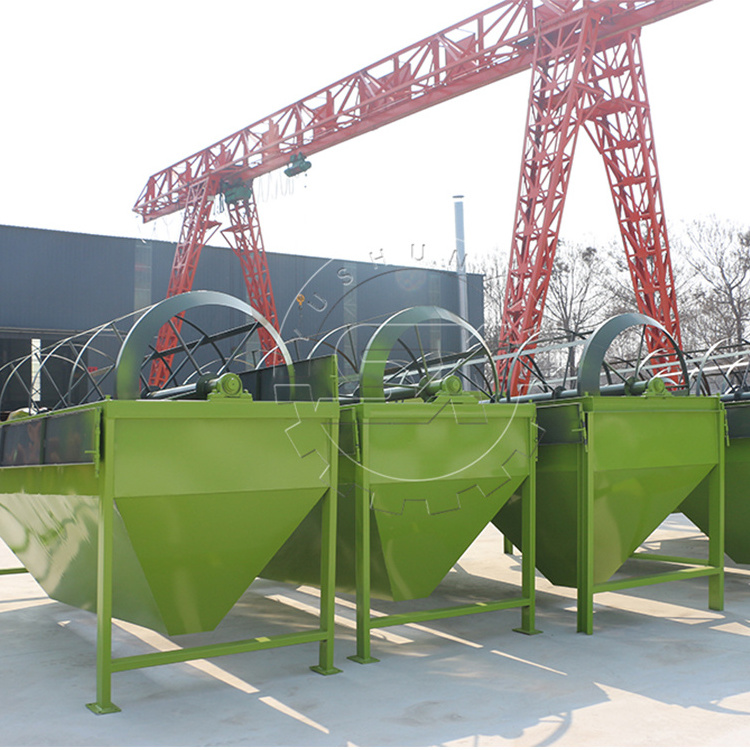

The rotary drum screen machine is a new type of self-cleaning material-screening special equipment. It is widely used in screening various solid materials that size less than 300mm. It has high efficiency, low noise, small amount of dust, long service life, less maintenance, easy maintenance and many other features. The screening capacity is 1 tons / hour ~20 tons / hour.

Suitable material:

powder compost; granules; sand; l

imestone powder, etc.

|

Model

|

Power(kw)

|

Reducer

|

Drum Speed (r/min)

|

Capacity(t/h)

|

|

SXGS-1020

|

3

|

3ZQ250

|

21

|

1-2t/h

|

|

SXGS-1030

|

3

|

3ZQ250

|

21

|

2-3t/h

|

|

SXGS-1240

|

4

|

4ZQ350

|

18

|

3-5t/h

|

|

SXGS-1540

|

5.5

|

5.5 ZQ350

|

16

|

5-8t/h

|

|

SXGS-1560

|

5.5

|

5.5 ZQ350

|

16

|

6-10t/h

|

|

SXGS-1870

|

7.5

|

7.5 ZQ450

|

12

|

12-15t/h

|

|

SXGS-2080

|

11

|

11 ZQ450

|

12

|

15-20t/h

|

Vibrating screening machine

Vibrating screen machine is specially designed and developed for the screening compound fertilizer by our company, the screen body is divided into two types: single layer and double layers. The mesh is made of high quality manganese steel, so it’s simple structure and easy to operate. Mesh size can be selected according to your requirements.

The working principle of the vibrating screen machine:

Power from the motor through v-belt transmit to the vibrator driving shaft and gear vibrator (speed ratio is 1), to achieve three axis rotating with same speed and resulting in vibration force, vibration exciter connected with screen box by high strength bolt, resulting in elliptical motion. Materials on the sieve machine with high speed elliptical motion randomly, quickly stratified, through the screen, and move forward, and finally complete the classification of materials.

Vibrating screen machine is specially designed and developed for the screening compound fertilizer by our company, the screen body is divided into two types: single layer and double layers. The mesh is made of high quality manganese steel, so it’s simple structure and easy to operate. Mesh size can be selected according to your requirements.

The working principle of the vibrating screen machine:

Power from the motor through v-belt transmit to the vibrator driving shaft and gear vibrator (speed ratio is 1), to achieve three axis rotating with same speed and resulting in vibration force, vibration exciter connected with screen box by high strength bolt, resulting in elliptical motion. Materials on the sieve machine with high speed elliptical motion randomly, quickly stratified, through the screen, and move forward, and finally complete the classification of materials.

Name:

Irene Ma

WhatsApp/WeChat:

+86 13017676980

Email:

irene at sxfertilizermachine.com

Hot Searches