- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110v,220v, 380v, To 680v,adjustable

-

Power:

-

adjustable according to volume

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

customized

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

50-50000L

-

Authentication:

-

CE PED,ISO 9001

-

Product Name:

-

Sanitary Stainless Steel Liquid Storage Tank

-

Tank type:

-

Standard/tapered

-

Key Selling Points:

-

Competitive Price

-

Name:

-

Wine Alcohol Storage Tank

-

Usage:

-

Liquid Products

-

Keyword:

-

Stainless Steel Oil Storage

Quick Details

-

Marketing Type:

-

New Product, New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zhongmao

-

Voltage:

-

110v,220v, 380v, To 680v,adjustable

-

Power:

-

adjustable according to volume

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

customized

-

Material:

-

Stainless Steel 304/316L

-

Capacity:

-

50-50000L

-

Authentication:

-

CE PED,ISO 9001

-

Product Name:

-

Sanitary Stainless Steel Liquid Storage Tank

-

Tank type:

-

Standard/tapered

-

Key Selling Points:

-

Competitive Price

-

Name:

-

Wine Alcohol Storage Tank

-

Usage:

-

Liquid Products

-

Keyword:

-

Stainless Steel Oil Storage

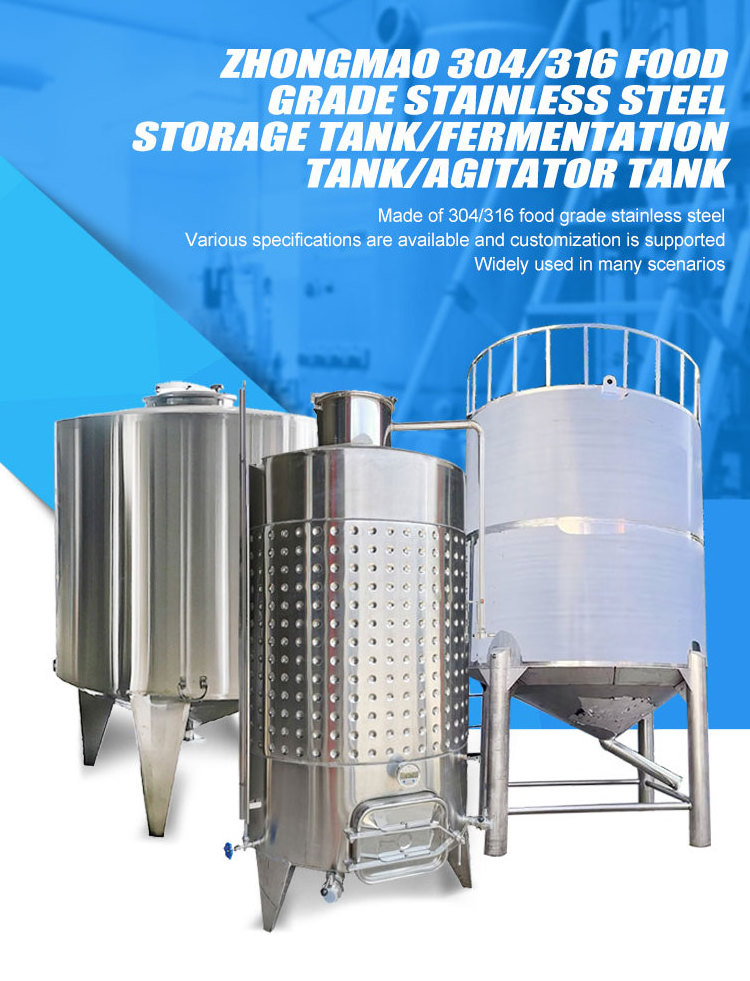

Products Description

Zhongmao has a variety of specifications for you to choose from. All products are certified by stainless steel materials. 100% tig welding joints and seams are used, and the interior is polished and sanitary. It is used in food, beverage, wine, beer, dairy, other industries. With 16 years of industry experience, we can customize any model to meet your needs.

STRUCTURE CHARACTERISTICS

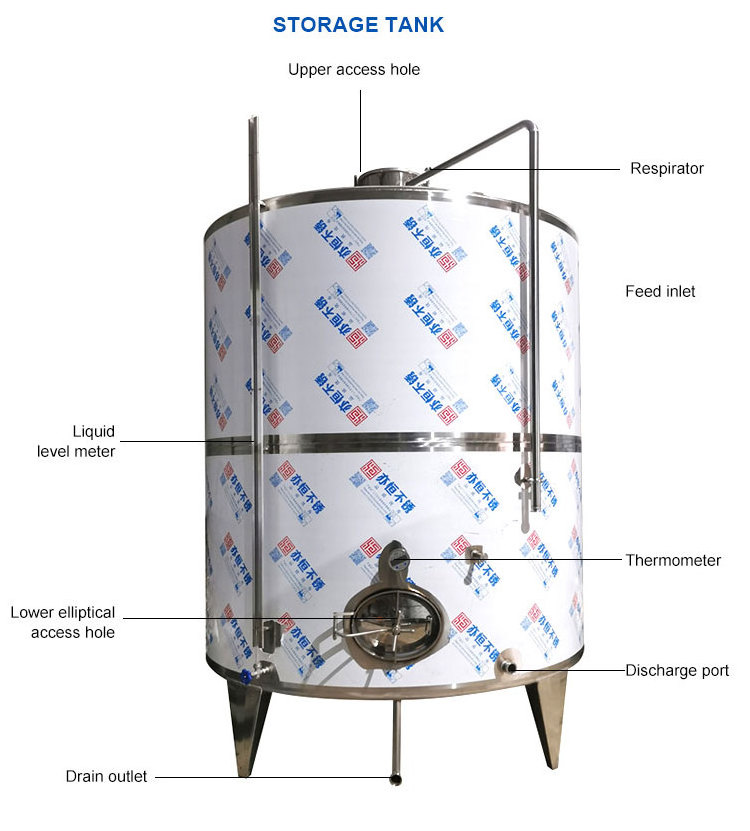

STORAGE TANK SPECIFICATION

According to storage capacity,the storage tanks are classified into tanks of 0.1-1000m³.The storage tank is made of sus316or 304 stainless steel.The thickness of the tank is 2-12 mm. And has good heat preservation performance.Support customers to customize on demand.

The actual specifications and parameters are subject to customization

|

Volume(m³)

|

1

|

2

|

3

|

5

|

10

|

20

|

30

|

50

|

|

Diameter(mm)

|

1000

|

1200

|

1450

|

1850

|

2050

|

2650

|

2800

|

3230

|

|

Can body(mm)

|

1220

|

1830

|

1830

|

1830

|

3050

|

3660

|

4880

|

6100

|

|

Total height(mm)

|

1760

|

2600

|

2600

|

2760

|

3980

|

4500

|

5400

|

6600

|

Made of 304 food grade stainless steel

Provide various specifications and support customization

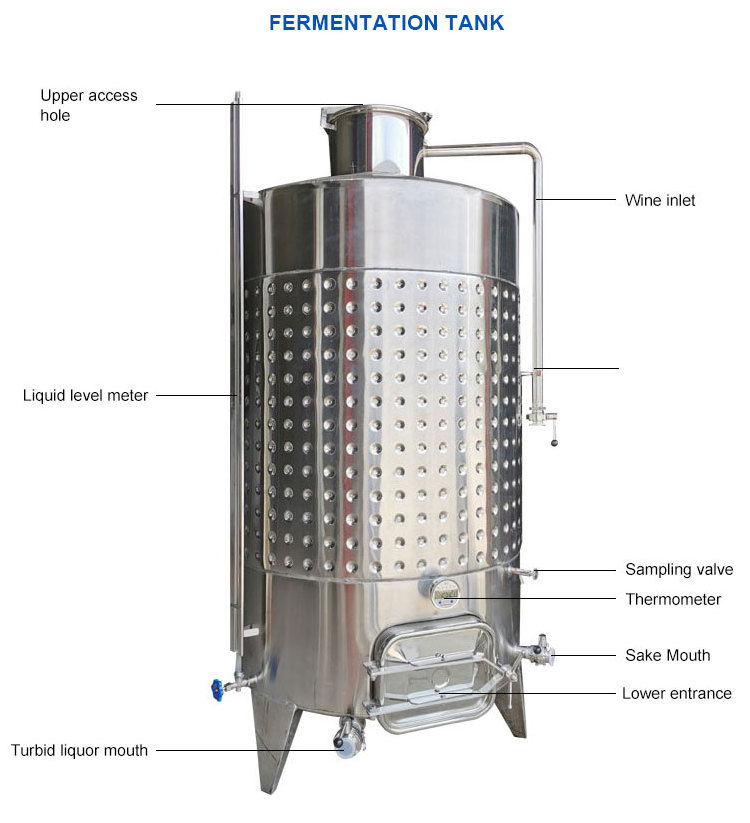

The latest fermentation tank is applicable to the fermentation, brewing and storage of grapes, apples and other fruits

|

volume(m³)

|

Size(mm)

|

Rated power(kw)

|

Net weight(kg)

|

temperature range

|

|

1m³

|

1050*1900

|

1.5

|

180

|

-20-100

|

|

2m³

|

1200*2600

|

1.5

|

230

|

-20-100

|

|

3m³

|

1450*2600

|

1.5

|

280

|

-20-100

|

|

5m³

|

1900*2800

|

2.2

|

400

|

-20-100

|

Good quality, quality assurance

Simple operation and flexible use

Full range, support customization

|

Zhongmao Agitator Tank

|

|

|

|

Mixer type:

Strong mixer

|

Application area:

food

|

|

|

Item Type:

Solid, liquid

|

Power type:

Electric

|

|

|

Layout form:

vertical

|

Mixing method:

Forced mixing

|

|

|

Operation mode:

Cyclic operation

|

Stirring drum shape:

Pear type

|

|

|

Throughput:

5000 (L/h)

|

Device mode:

Fixed

|

|

|

Motor power:

3(Kw)-5.5(Kw)

|

Speed range:

32(r/min)-2000(r/min)

|

|

|

Barrel capacity:

1000(L)-5000(L)

|

Specifications:

1-20m³

|

|

1. Suitable for industries such as food, dairy, beverages, cosmetics, etc.

a. Chemical industry: fats, solvents, resins, paints, pigments, oil agents, etc.

b. Food industry: yogurt, ice cream, cheese, soft drinks, jelly, tomato sauce, oil, syrup, chocolate, etc.

c. Daily chemical products: facial foam, hair gel, hair dye, toothpaste, shampoo, shoe polish, etc.

Please consult us for more applicable information, which can be made as needed.

Design and manufacture mixing tanks according to customer specific needs and requirements

1,Capacity: The capacity of the mixing tank needs to be determined based on the product and production process produced by the customer.

2,Material: The mixing tank can be made of stainless steel, carbon steel, fiberglass, etc. Select the appropriate material according to customer needs.

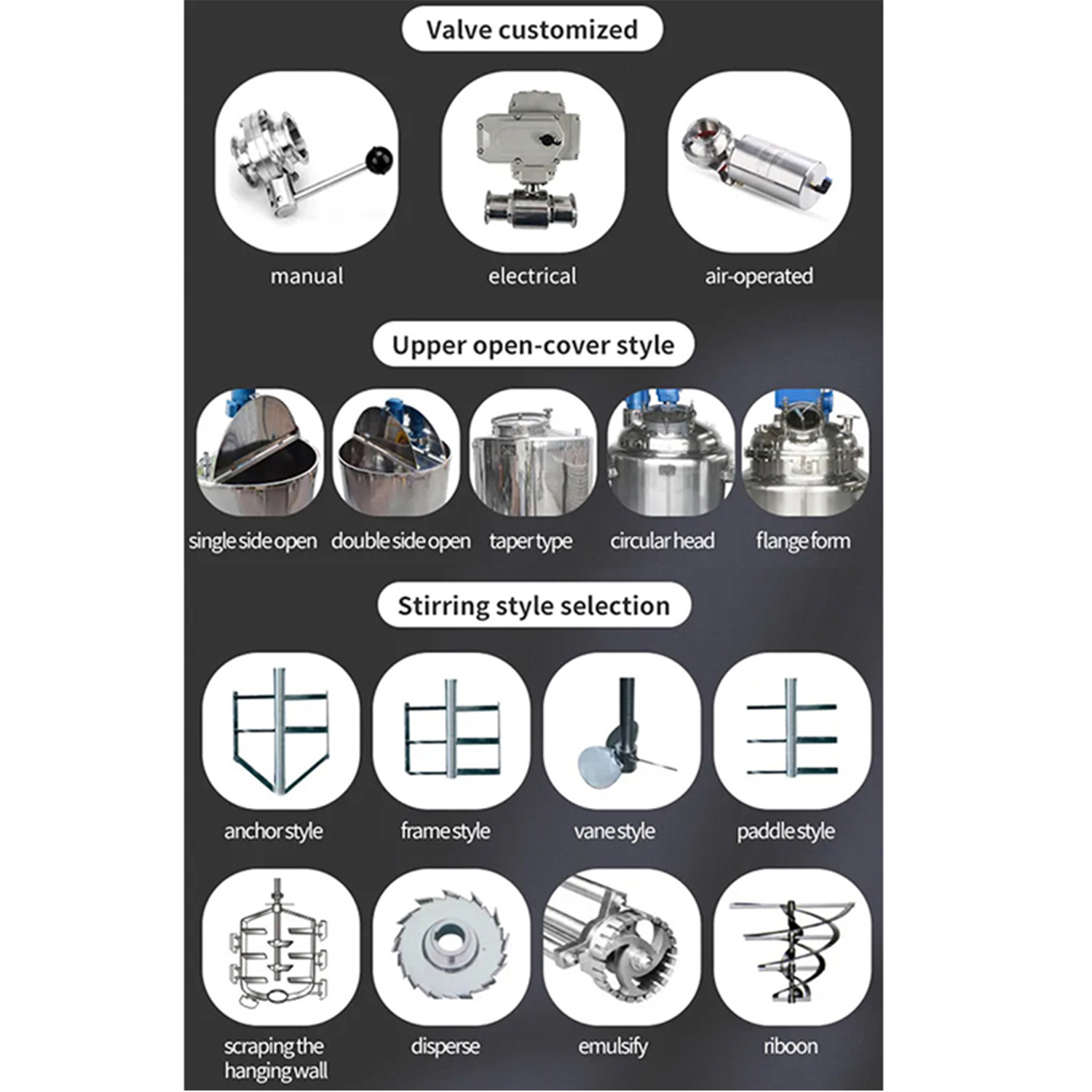

3,Mixing method: The mixing tank can adopt mechanical mixing or gas mixing, and the mixing method needs to be determined based on the characteristics of the customer's product and production process.

4,Temperature and pressure requirements: The design of the mixing tank needs to consider the temperature and pressure requirements of the customer's product to ensure that the mixing tank can work normally during the production process.

5,Other special requirements: For example, the customer needs the mixing tank to have special functions such as anti-corrosion and explosion-proof, which need to be considered during the design and manufacturing process.

Product Display

Production Process

Application

Applicable to the fields of food, dairy, beverage, cosmetic etc industry.

a. Chemical Industry: Fat, Dissolvent, Resin, Paint, Pigment, Oil Agent etc.

b. Food Industry: Yogurt, Ice Cream, Cheese, Soft Drink, Fruit Jelly, Ketchup, Oil, Syrup, Chocolate etc.

c. Daily Chemicals: Facial Foam, Hair Gel, Hair Dyes, Toothpaste, Shampoo, Shoe Polish etc.

With years of production experience and excellent r&d and service teams, we have been providing family brewers, commercial brewers and food with cost-effective high-quality stainless steel tanks and fermentation tanks to promote the rapid development of the industry. We provide a series of storage tanks and fermentation tanks specially designed for small and growing distilleries. For many years, we have been cooperating with some of the best tank manufacturers in europe and the united states to provide you with a full range of storage tanks at affordable prices, with all the functions and functions required for successful harvest.

Product packaging

We have rich experience in the whole packaging and transportation process, and use different materials to provide adequate internal protection, including iron frames, wooden boxes, foam boards, etc. We will avoid any damage during transportation, and strictly follow the packaging process to ensure the safety and integrity of the goods.

Hot Searches