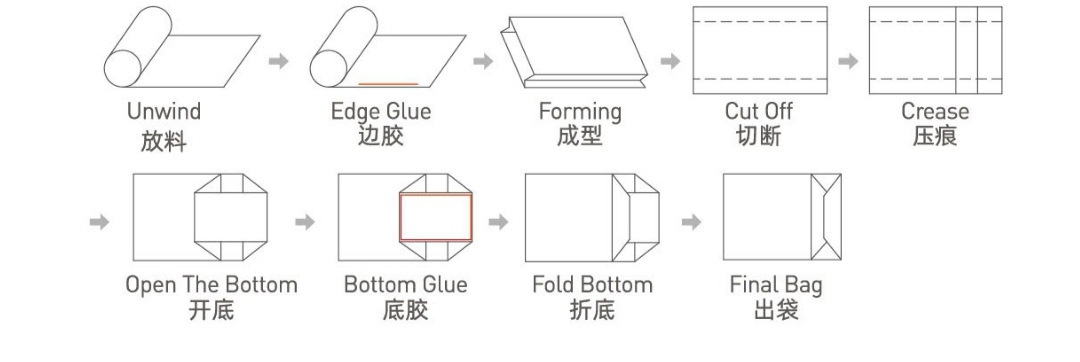

Edge Glue

Forming

Cut off

Crease

Open the Bottom

Bottom Glue

Fold Bag

Final Bag