- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Aluminum Die Cast Furniture Hardware

-

Material:

-

Aluminum Alloy

-

Color:

-

Customer Request

-

Service:

-

OEM ODM

-

Package:

-

Polybag+carton+pallet

-

Weight:

-

customized

-

Sample:

-

Availabe

-

Design:

-

STEP,CAD

-

Surface treatment:

-

Electroplatable Color White Zinc

-

Advantage:

-

Strong Structure

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

EASTEEL

-

Model Number:

-

die casting

-

Name:

-

Aluminum Die Cast Furniture Hardware

-

Material:

-

Aluminum Alloy

-

Color:

-

Customer Request

-

Service:

-

OEM ODM

-

Package:

-

Polybag+carton+pallet

-

Weight:

-

customized

-

Sample:

-

Availabe

-

Design:

-

STEP,CAD

-

Surface treatment:

-

Electroplatable Color White Zinc

-

Advantage:

-

Strong Structure

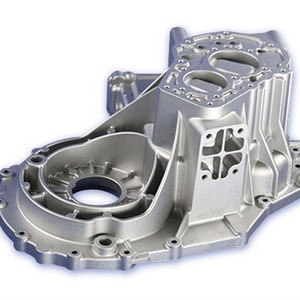

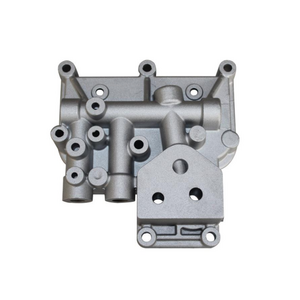

Products Description

|

Material & Temper

|

Aluminum Alloy ADC12 ,A380 or customized .

|

|

Film Standard

|

Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ.

|

|

Casting tolerance

|

from 3 g --- 20kgs

|

|

Part Weight

|

AISI, ANSI, ASTM, JIS, GB, ISO, DIN

|

|

Thickness

|

0.4mm-20mm or Customized.

|

|

Surface Treatment

|

Mill-Finished, Powder Coating,Polishing, Brushing, etc.

|

|

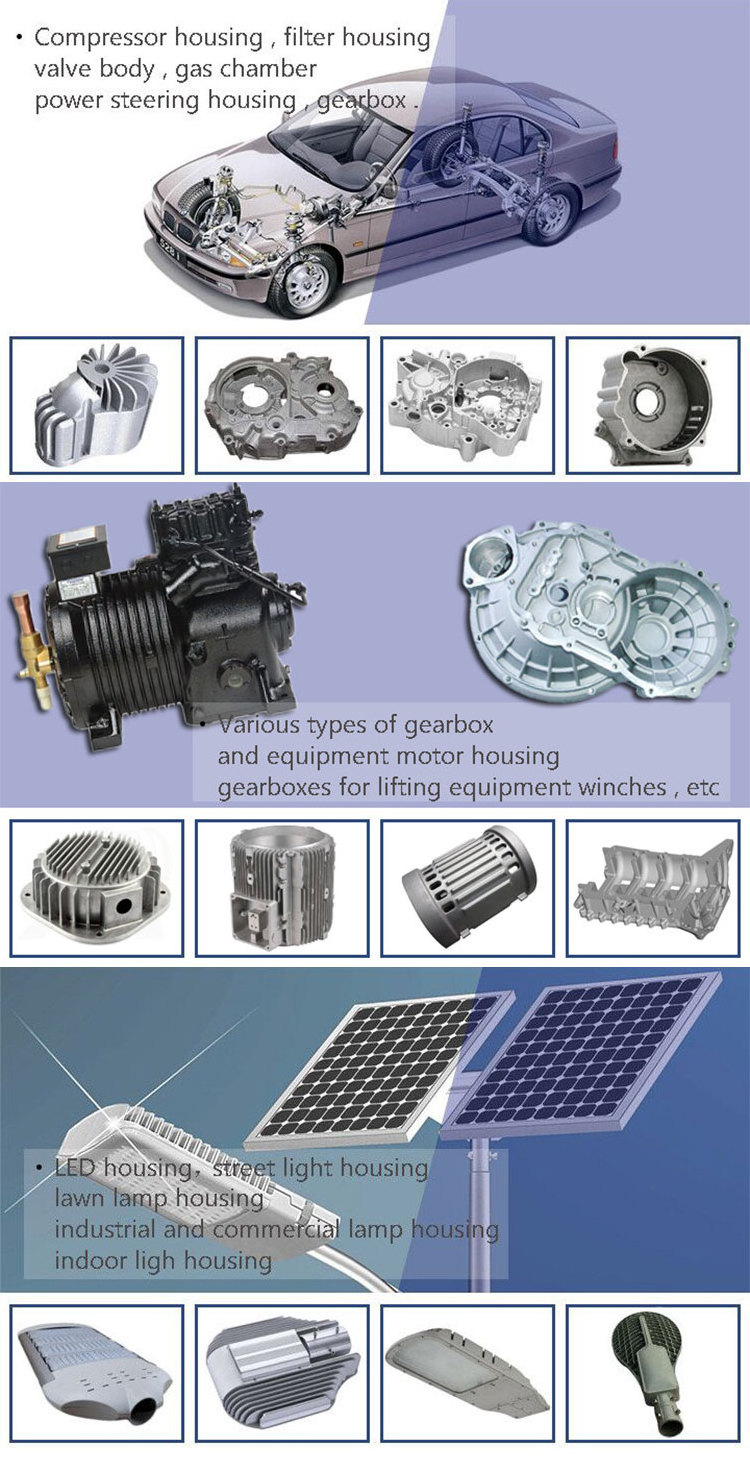

Application

|

Industry fittings and Construction and Decoration.

|

|

Casting Machine

|

200-1200 tons

|

|

Capability

|

Output 100 tons per month.

|

|

Deep Processing

|

CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling

|

|

Film Standard

|

As custimer's . Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ.

|

|

MOQ

|

Ra 1.6-Ra12.5

|

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

We have a professional engineer team to design custom parts for your remand, we also have a lot of ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

Production Process

Customer Comments

Related Products

Our Company

Certificate

FAQ

|

Q1.What is the specific fabrication process ?

|

|

Die designing→Die making→Smelting&alloying→QC→Die casting→remove burrs→QC→Surface treatment→QC

→Packing→QC→Shipping→After Sale Service

|

|

Q2.What's the production time for new molds and mass production?

|

|

7-10 days to make the new moulds, mass production takes around 20-25days,can process urgently if need

|

|

Q3.Can you send me samples ?

|

|

Yes, Samples are for free, and freight is on your side.

|

|

Q4.How long is the lifetime ?

|

|

Anodizing for 12-15 years outdoor, Powder coating for 18-20 years outdoor.

|

|

Q5.What is the payment terms ?

|

|

T/T: 30% deposit, the balance will be paid before delivery;

L/C: the balance irrevocable L/C at sight. |

Hot Searches