- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HONG KY

-

Voltage:

-

380V

-

Power:

-

350KW

-

Dimension(L*W*H):

-

48m x 4m x 3.5m

-

Weight:

-

24500 kg

-

Pipe material:

-

Carbon steel, Galvanized steel

-

Pipe Diameter:

-

12.7 mm - 42 mm

-

Thickness:

-

0.5 mm - 2 mm

-

Total Power:

-

350Kw

-

Export port:

-

Ho Chi Minh Port

-

Speed:

-

30-100m/min

-

Cutting system:

-

Cold or hot cutting

-

Advantage:

-

Productivity, stability, best quality of fabrication

-

After-sell service:

-

on site installation and training

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

30-100mm/min

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

HONG KY

-

Voltage:

-

380V

-

Power:

-

350KW

-

Dimension(L*W*H):

-

48m x 4m x 3.5m

-

Weight:

-

24500 kg

-

Pipe material:

-

Carbon steel, Galvanized steel

-

Pipe Diameter:

-

12.7 mm - 42 mm

-

Thickness:

-

0.5 mm - 2 mm

-

Total Power:

-

350Kw

-

Export port:

-

Ho Chi Minh Port

-

Speed:

-

30-100m/min

-

Cutting system:

-

Cold or hot cutting

-

Advantage:

-

Productivity, stability, best quality of fabrication

-

After-sell service:

-

on site installation and training

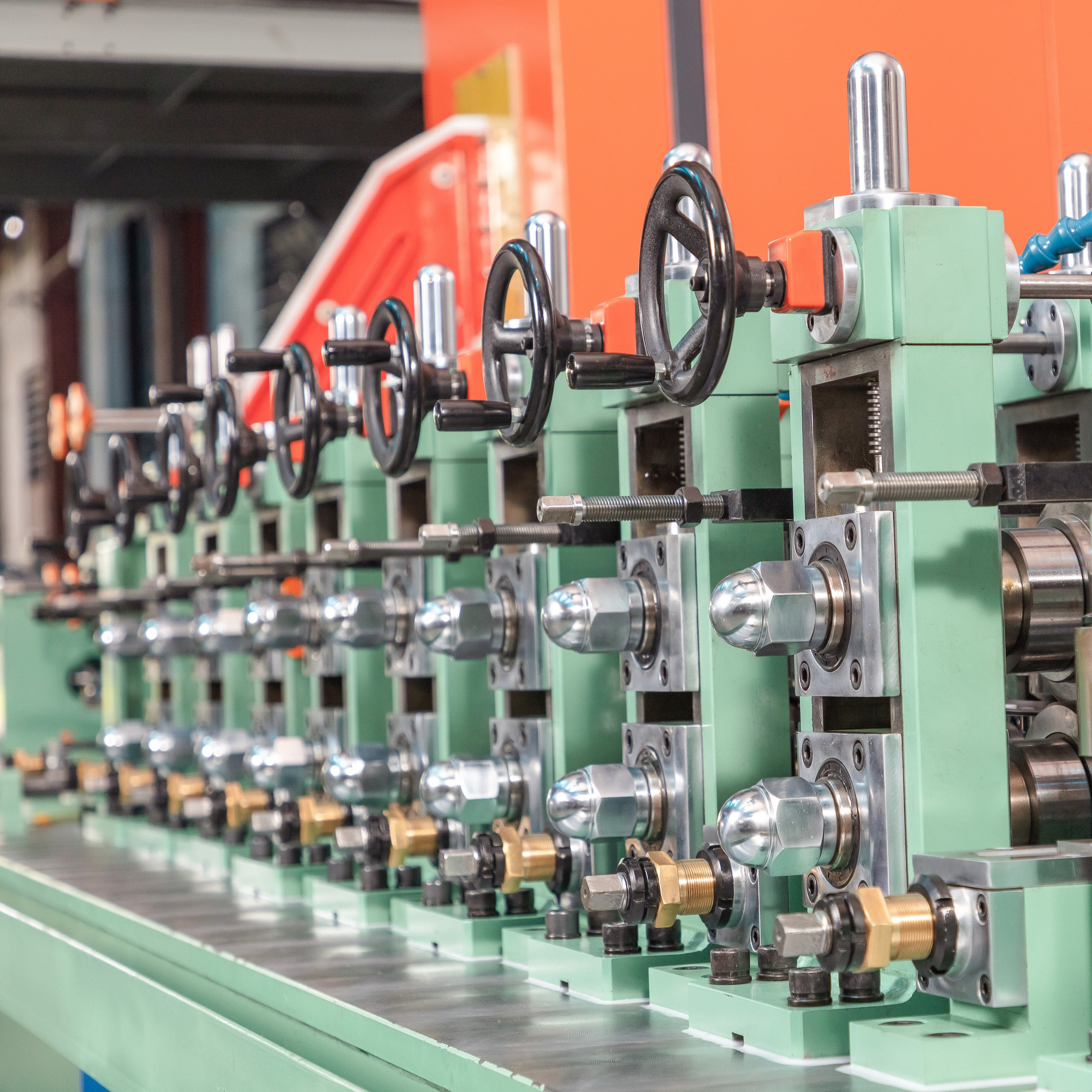

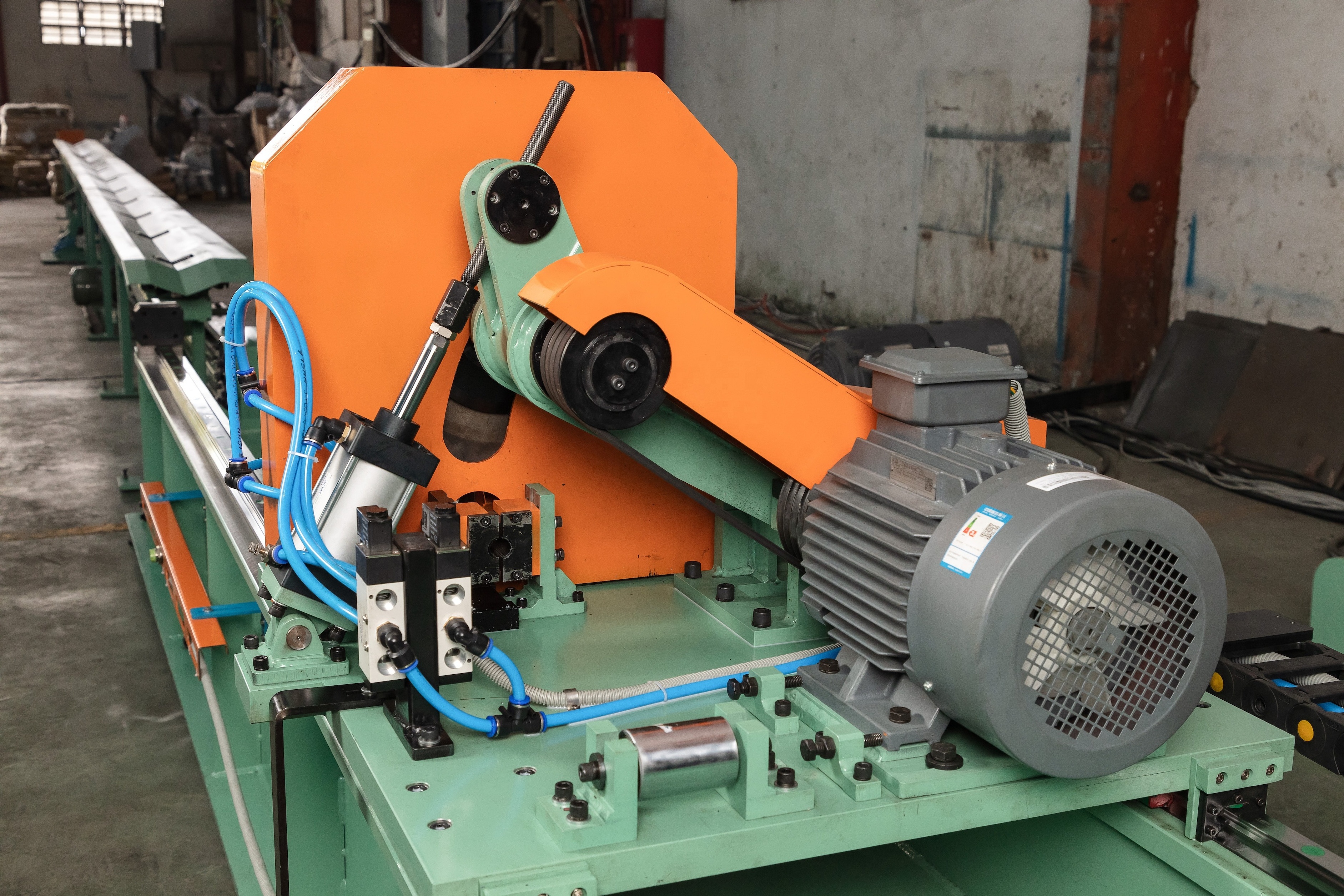

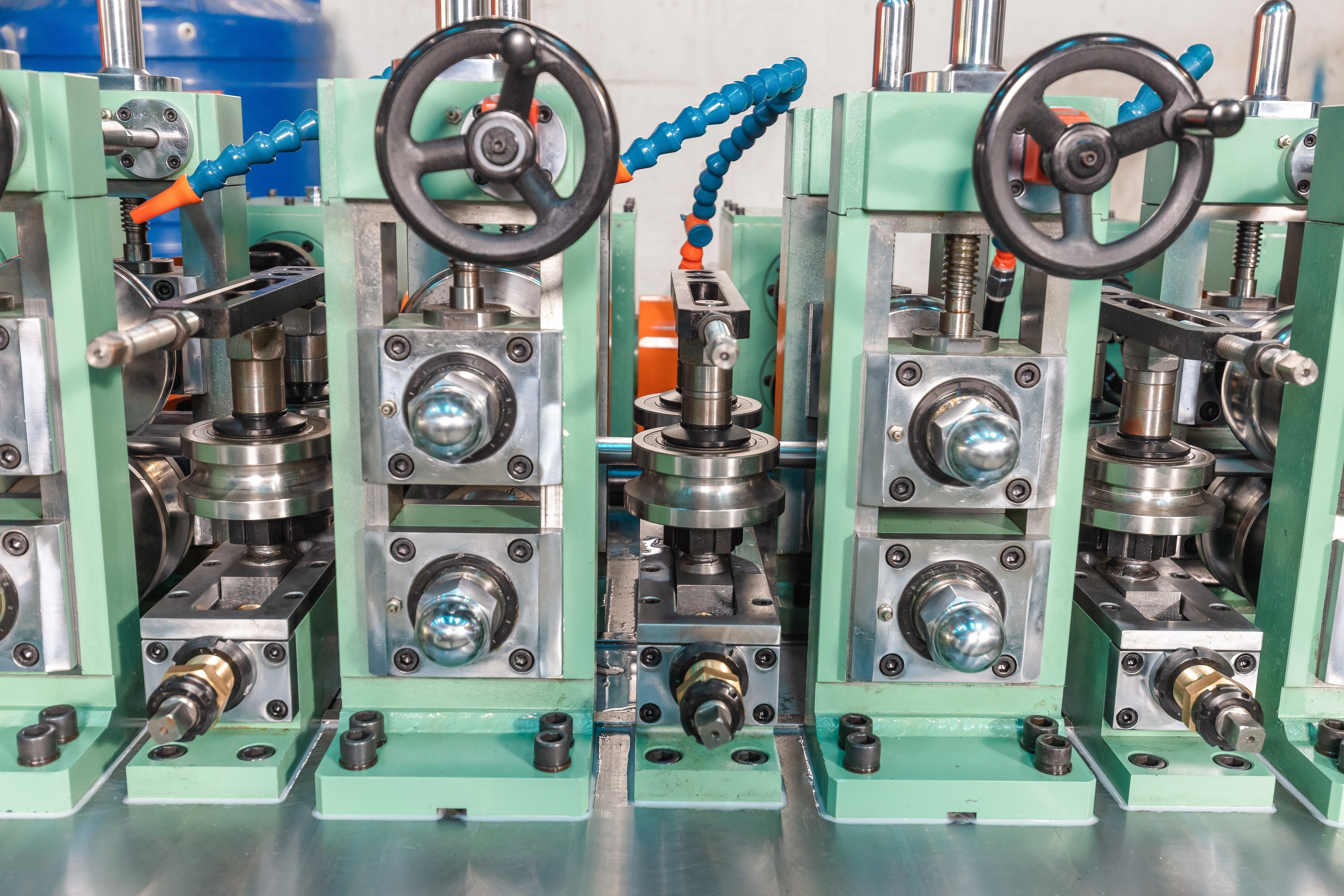

Product Description

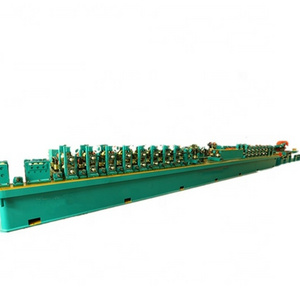

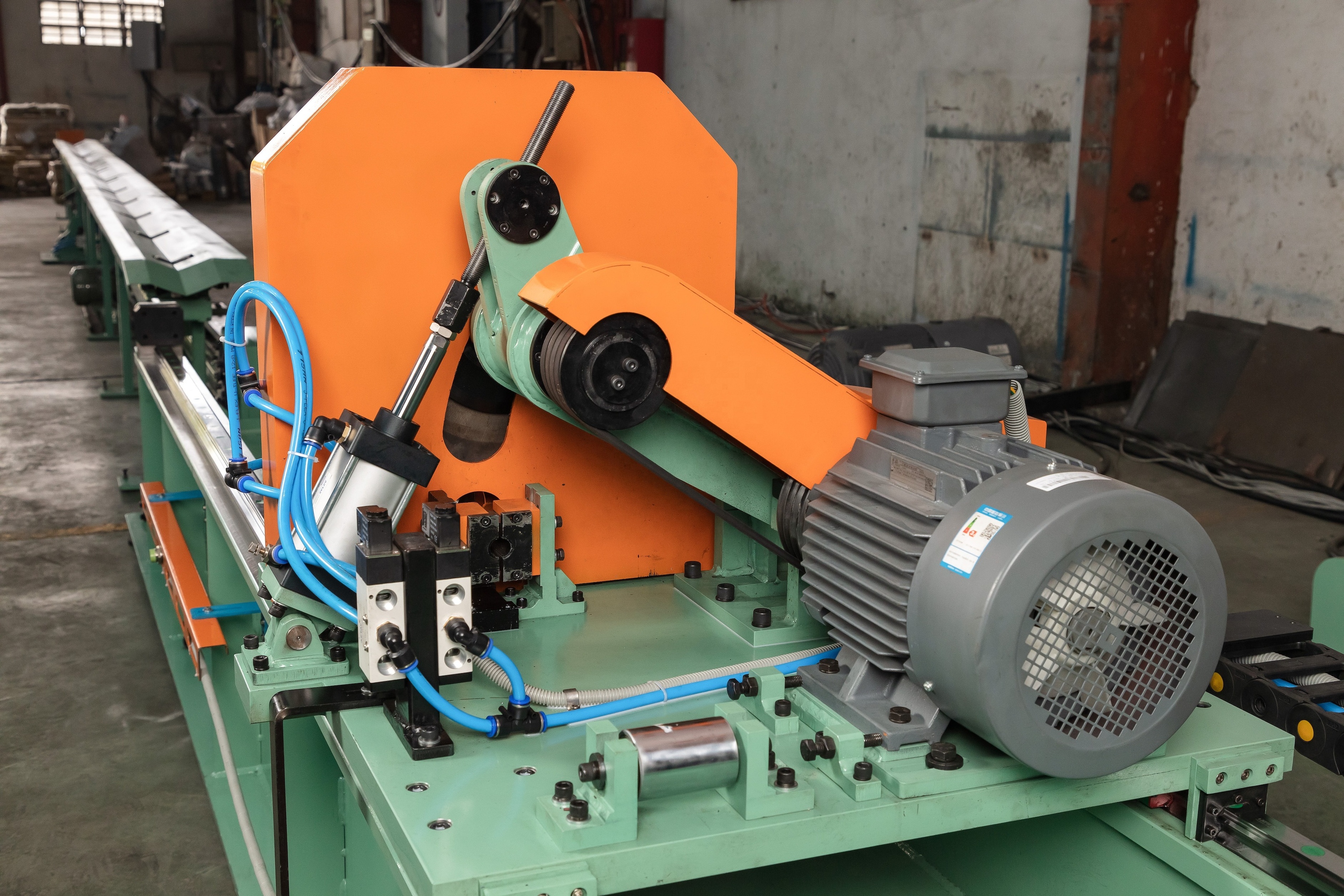

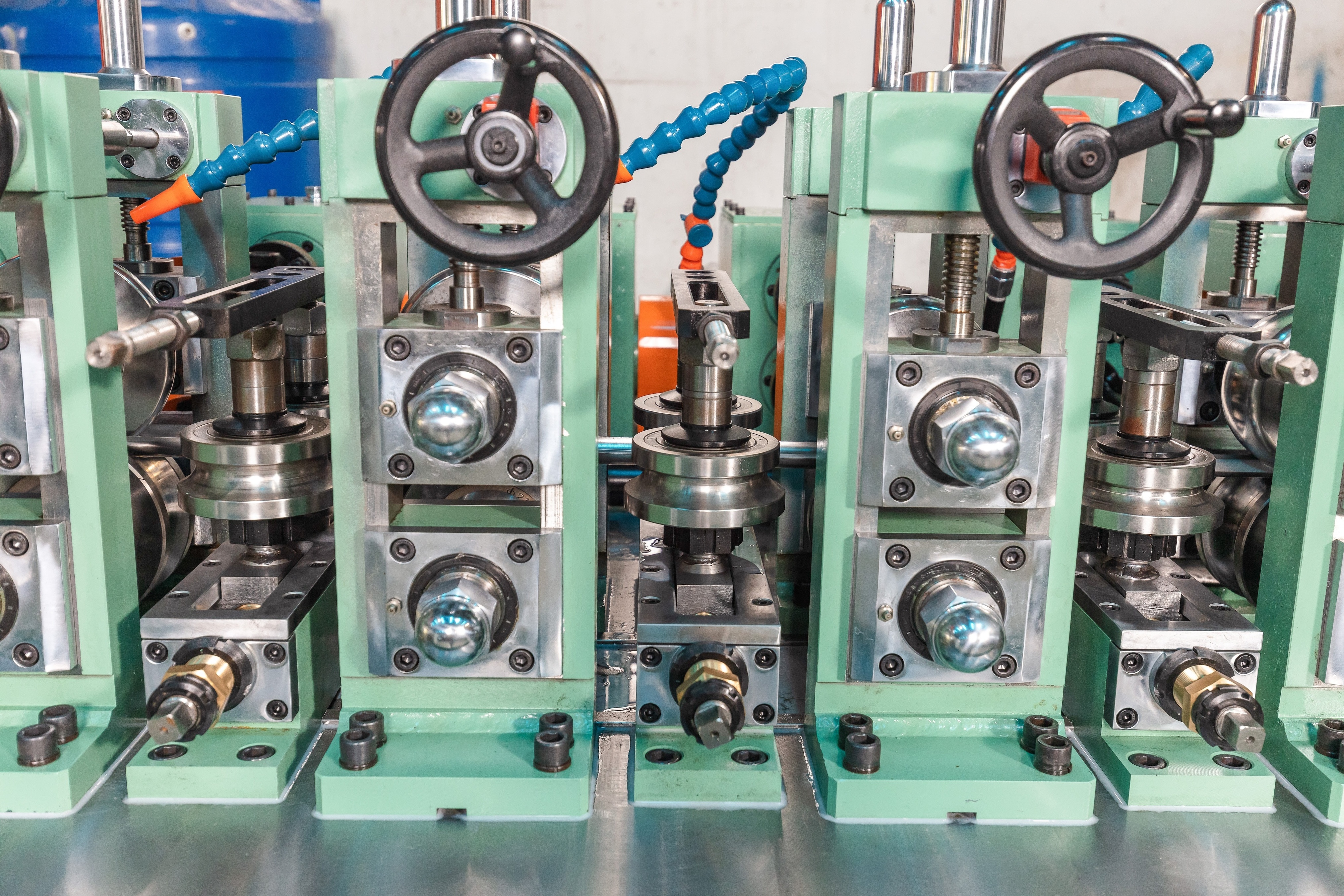

HONG KY Welded Pipe Making Machine - model HK-S32 is designed to produce the steel tubes based on the required dimensions. This machine is used in the manufacturing factories of wide range of products such as factory frame, scaffolding, water pipe, lighting poles, home appliances, furniture, etc. It uses the high frequency welding machine (mosfet technology) to weld tubes

.

HONG KY Welded Pipe Making Machine – model HK-S32 was designed and made in Viet Nam. With more than 35 years in mechanical engineering and the experienced research and design team, Hong Ky commits to provide our clients the full packaged services including consultancy, design, manufacture, installation, warranty, and maintenance. The unique selling point of Hong Ky is stability, durability to contribute to improving the working efficiency.

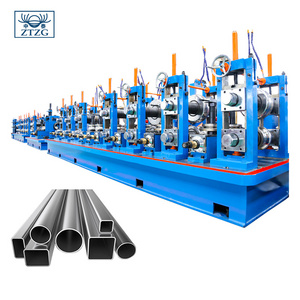

Specification

|

Description

|

value

|

|

Type of pipe

|

Round, rectangular, square

|

|

Material

|

Low carbon steel, Galvanize steel

|

|

Diameter of round pipe

|

Ø 12.7 ~ Ø 42 mm

|

|

Thickness of round pipe

|

0.5 - 2 mm

|

|

Square tube size

|

12 x 12 - 30 x 30 mm

|

|

Thickness of square pipe

|

0.5 - 2 mm

|

|

Rectangular tube size

|

9 x 13 - 20 x 40 mm

|

|

Thickness of rectangular pipe

|

0.5 - 2 mm

|

|

Speed

|

30 - 100 mpm

|

|

Tube cutting length

|

4 -8 m

|

|

Main motor capacity

|

110Kw

|

|

High frequency power

|

150Kw

|

Our Advantages

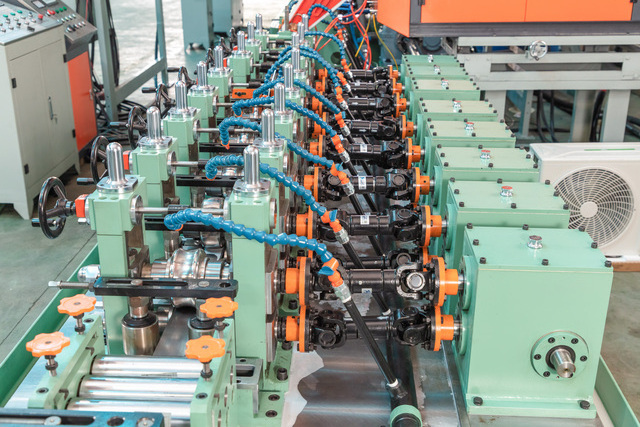

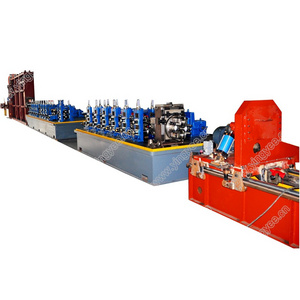

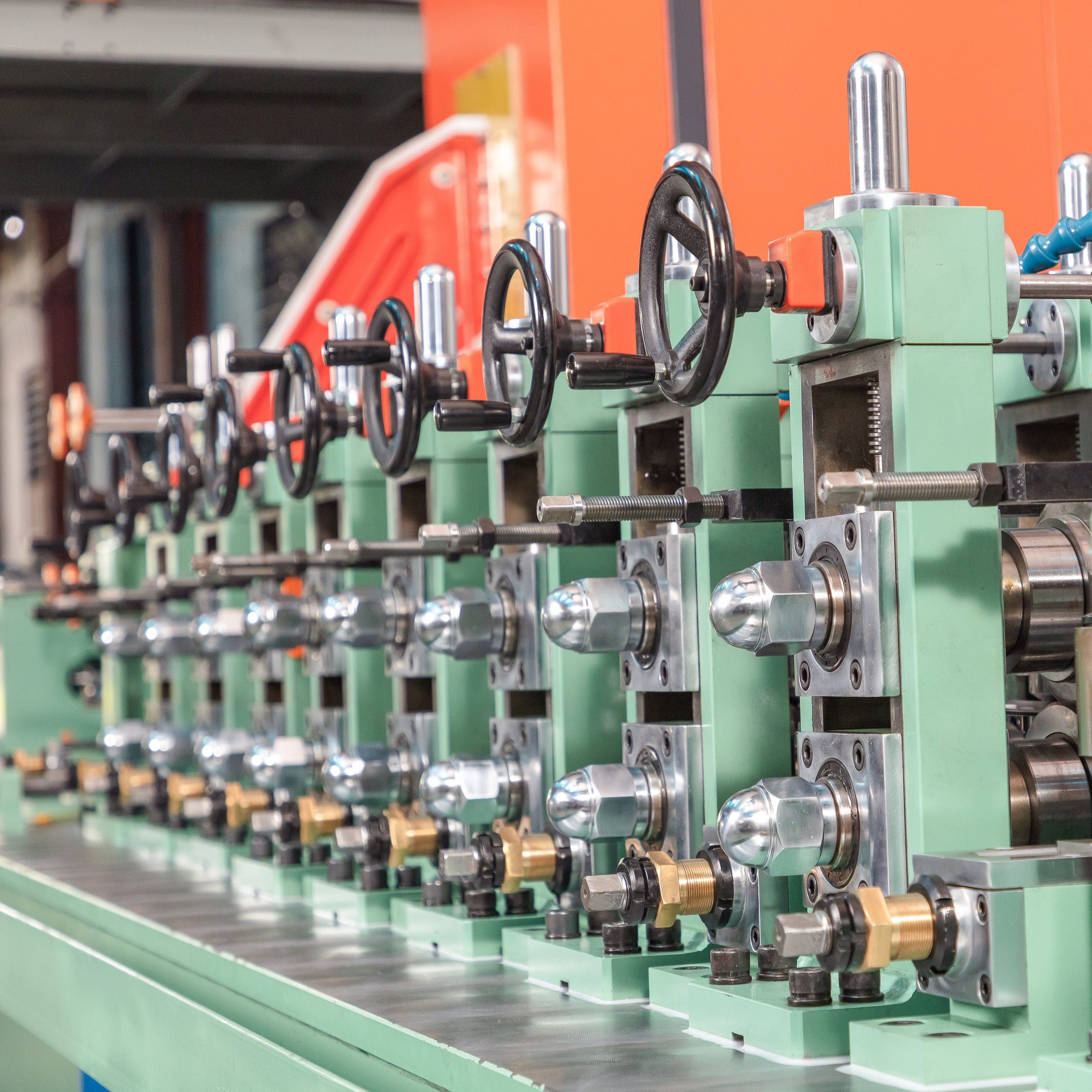

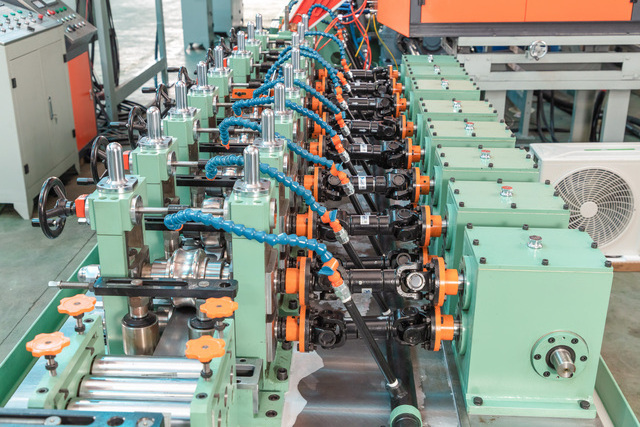

* Since all hydraulic pipes, and water pipes, electrical wires are buried underground, the working ground is clean and easy for operator to work. It is also equipped safety fences at horizontal accumulator, sensors at hot cutting saw which provide the highest safety working place for the operator.

* The design was applied new horizontal accumulator which can store more steel strips and reduce the folding or broken steel trips comparing with vertical accumulator. Thanks to this horizontal accumulator, the machine operates stably and highly efficient.

* The programing logic control system PLC combines with smart touch screen HMI which operator can monitor the slitting machine easily.

* The highly automatic operation brings client the high productivity.

Hot Searches