Double Roll:materials alloy steel

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

30000 KG

-

Applicable Industries:

-

Tire Recycling Machine

-

Raw material:

-

Used Tire

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUXI

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

30000 KG

-

Applicable Industries:

-

Tire Recycling Machine

-

Raw material:

-

Used Tire

-

Certification:

-

CE ISO

Products Description

Configuration Line

|

No.

|

Content

|

Power

|

Qty.

|

|||

|

Steel Wire Removal Process

|

|

|

|

|||

|

1

|

tire steel wire drawing machine

|

11KW

|

1

|

|||

|

Rubber Block Process

|

|

|

|

|||

|

2

|

belt conveyor

|

5.5KW

|

2

|

|||

|

3

|

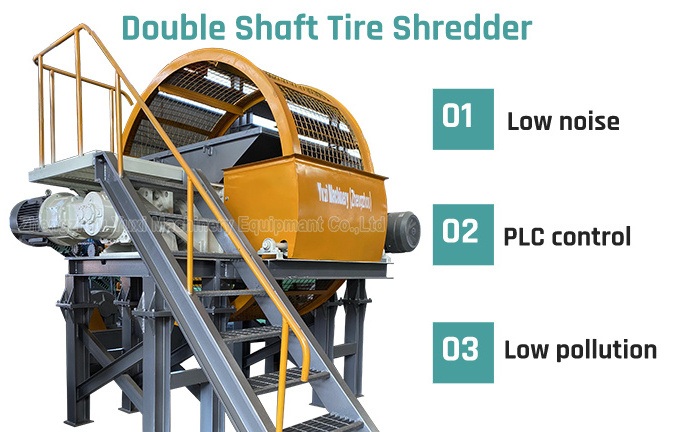

double shaft tire shredder

|

45*2kw

|

1

|

|||

|

Rubber Granular Process

|

|

|

|

|||

|

4

|

separate steel wire machine

|

45kw

|

1

|

|||

|

5

|

magnetic Separator

|

0.75*2kw

|

1

|

|||

|

6

|

Rubber Granular

|

37kw

|

1

|

|||

|

Rubber Grinding Process

|

|

|

|

|||

|

7

|

Grinder Machine

|

50kw

|

2

|

|||

|

Dust Removal Process

|

|

|

|

|||

|

8

|

Magnetic Separator

|

0.75kw

|

1

|

|||

|

9

|

Fiber separator

|

5.5+7.5kw

|

1

|

|||

|

10

|

Dust removal equipment

|

5.5kw

|

1

|

|||

|

11

|

......

|

......

|

......

|

|||

Please contact us for more detailed parameters

Application

Raw Materials

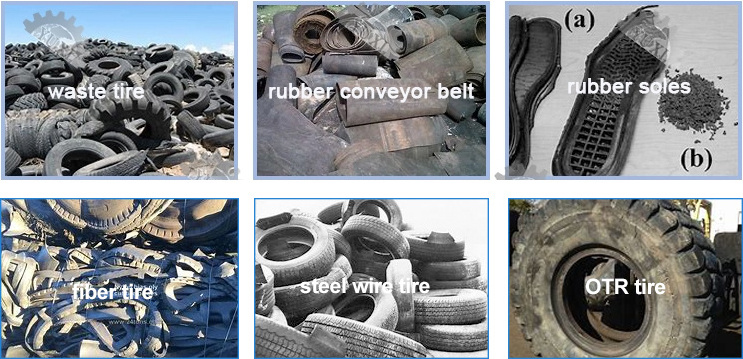

Waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires are the most.

Finally Product

Rubber Granule Sze: 0-6 mm

Rubber Powder Size: 5-120 Mesh

What Is The Application of Used Tires?

Recycling of used tires after smashing has become a new industry hotspot and development trend.

The following product applications are for your reference

1.8-20 mesh

, mainly used for runways, road cushions, sports pavements, etc.

2.30-40 mesh

, mainly used for reclaimed rubber, paving, producing rubber sheets

3.40-60 mesh

, mainly used for rubber rubber filling, plastic modification

4.60-80 mesh

, mainly used in automobile tires, rubber products, building materials

Working Process

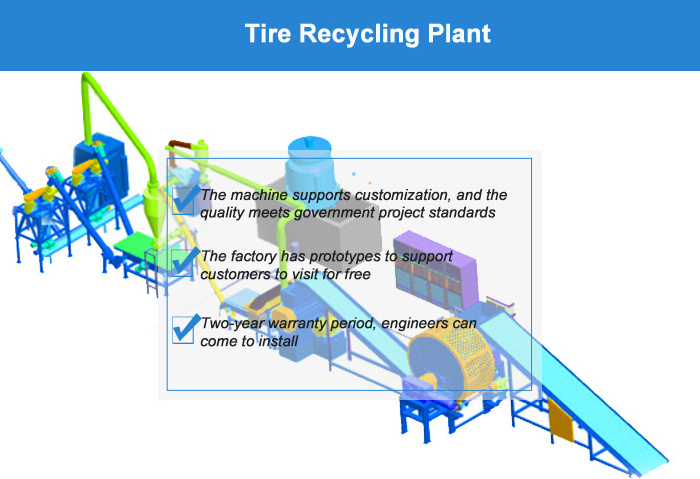

1.Conveyor

-Transport the tire to the shredder;

2.Double shaft shredder

---Shears the tire into 5-10 cm blocks;

3.Recirculation system

---To control the size of shreds going to the raspers;

4.Raspers

-Reduce the shreds into 15-20 mm chips and liberates steel from the rubber;

5.Over belt magnet

--Separation of liberated steel from the rubber chips;

6.Vibratory feeder

--Transports the rubber chips;

7.Granulator

--Size reduction of the chips to 1-4 mm granules and liberates the textile fraction to air flow separation.

8.Vibratory screen

-Sorts the granules by size and removes the majority of textile;

9.Classifer

-Removal of remaining textile;

10.Drum magnet

-Removal of remaining steel fines;

11.Central de-dusting unit

--Remove dust and fines from the system and filter the air before returning it to the atmosphere.

Details Images

steel wire drawing machine

Motor Power:11kw

Round Trip Speed:1.5times/min

Weight:1200kg

Dimension:1300*1000*1300MM

Capacity:60-80 pieces

Shredder Machine

Waste tire less than 1200mm and rubber materials can be crushed into 50*50 mm block.

The machine consists of rack,cavity, motor, hydraulic coupling, reducer, a group of moving blades, two sets of blades, screen, hydraulic system.

Steel Wire Separator

Input materials

≤50mm tire rubber blocks

Finally products

≤20mm. and can remove 96% of the tire steel wire

Motor

: as per request

Reducer

: as per request

Rubber Grinder

The rubber grinder is a device that pulverizes 2-6mm pure rubber granules into a fine powder of10-140 mesh at room temperature.

Motor

: as per request

Product size:

one or more sizes are discharged at the same time

Why Choose Us

Provide you with more choose

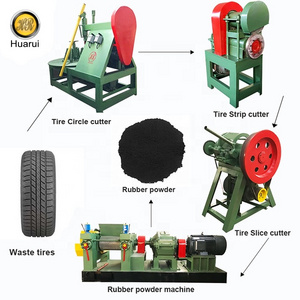

Semi-Automatic Waste Tire Recycling Machine

The semi-automatic type machine includes steel wire drawing machine, tire cutting machine, double shaft shredder, rubber mill, fiber separator, rubber grinder, centrifugal screen.

More customer site for your visit

The factory is strong and can be delivered on time

FAQ

Q:How to Choose A Suitable Tire Recycling Line?

A: Please tell us your capacity and the output size, we will recommend you the most suitable tire recycling line.

Q: Can We Get Very Fine Powder From The Recycling Line?

A: Yes, you can get 20-120mesh fine rubber powder with fine grinder system.

Q: Can You Process OTR Tires?

Q: Can We Get Very Fine Powder From The Recycling Line?

A: Yes, you can get 20-120mesh fine rubber powder with fine grinder system.

Q: Can You Process OTR Tires?

A: Yes, we have machines special for OTR tires, like OTR tire cutter machine, OTR tire bead cutting machinery, etc.

Q: What About The Machine Installation?

A: We will send engineers to customer working site for the installation guidance, commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

Q: How About The Spare Parts?

A: We provide spare parts at cost price permanently and will give you the spare parts list when you purchase machine.

Q: Will You Test The Machine Before Delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

A: We will send engineers to customer working site for the installation guidance, commissioning and training when everything is ready on the working site, like power, cable, labors, forklift, etc.

Q: How About The Spare Parts?

A: We provide spare parts at cost price permanently and will give you the spare parts list when you purchase machine.

Q: Will You Test The Machine Before Delivery?

A: Yes, we will test every machine and production line before delivery and send you the working video. You also can come to us for inspection before delivery.

Hot Searches