*Standardized workshop of total 2000 square meters.Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier & Korea Daewoo, ensure the precision of parts.

*The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

*Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

*Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

*Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HENGMEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country, 380V 50Hz 3Phase

-

Dimension(L*W*H):

-

3850*2200*2200mm

-

Hollow part volume:

-

2L

-

Power (kW):

-

25

-

Weight (KG):

-

3500 KG

-

Keywords:

-

Plastic Machine Preform Bottle Blowing Machine

-

Output:

-

<12000bph

-

Cavity:

-

1-8 cavity

-

Jar diameter:

-

45-120mm

-

Jar height:

-

50-300mm

-

Jar neck diameter:

-

55-105mm

-

Suitable bottle:

-

Plastic bottle

-

Bottle material:

-

PET Material

-

Product name:

-

Plastic Machine Preform Bottle Blowing Machine

Quick Details

-

Neck Diameter(mm):

-

105 mm

-

Max.Bottle Diameter(mm):

-

120 mm

-

Max.Bottle Height(mm):

-

300 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HENGMEI

-

Year:

-

New

-

Voltage:

-

Acoording customer country, 380V 50Hz 3Phase

-

Dimension(L*W*H):

-

3850*2200*2200mm

-

Hollow part volume:

-

2L

-

Power (kW):

-

25

-

Weight (KG):

-

3500 KG

-

Keywords:

-

Plastic Machine Preform Bottle Blowing Machine

-

Output:

-

<12000bph

-

Cavity:

-

1-8 cavity

-

Jar diameter:

-

45-120mm

-

Jar height:

-

50-300mm

-

Jar neck diameter:

-

55-105mm

-

Suitable bottle:

-

Plastic bottle

-

Bottle material:

-

PET Material

-

Product name:

-

Plastic Machine Preform Bottle Blowing Machine

Suitable PET Jar / Wide-mouth Bottle

Plastic PET Jar / Wide-mouth Bottle Drawing

Product Description

Full automatic blow molding machine.

Bottle: Max 0.6L

Max output: 16,000bph

Neck size: 30mm

Full automatic blow molding machine.

Bottle: Max 2L

Max output: 15,000bph

Neck size: 30mm

Max output: 15,000bph

Neck size: 30mm

Full automatic blow molding machine.

Bottle: Max 20L

Max output: 4,000bph

Neck size: 72mm

Max output: 4,000bph

Neck size: 72mm

|

Model

|

HM-G2L4C

|

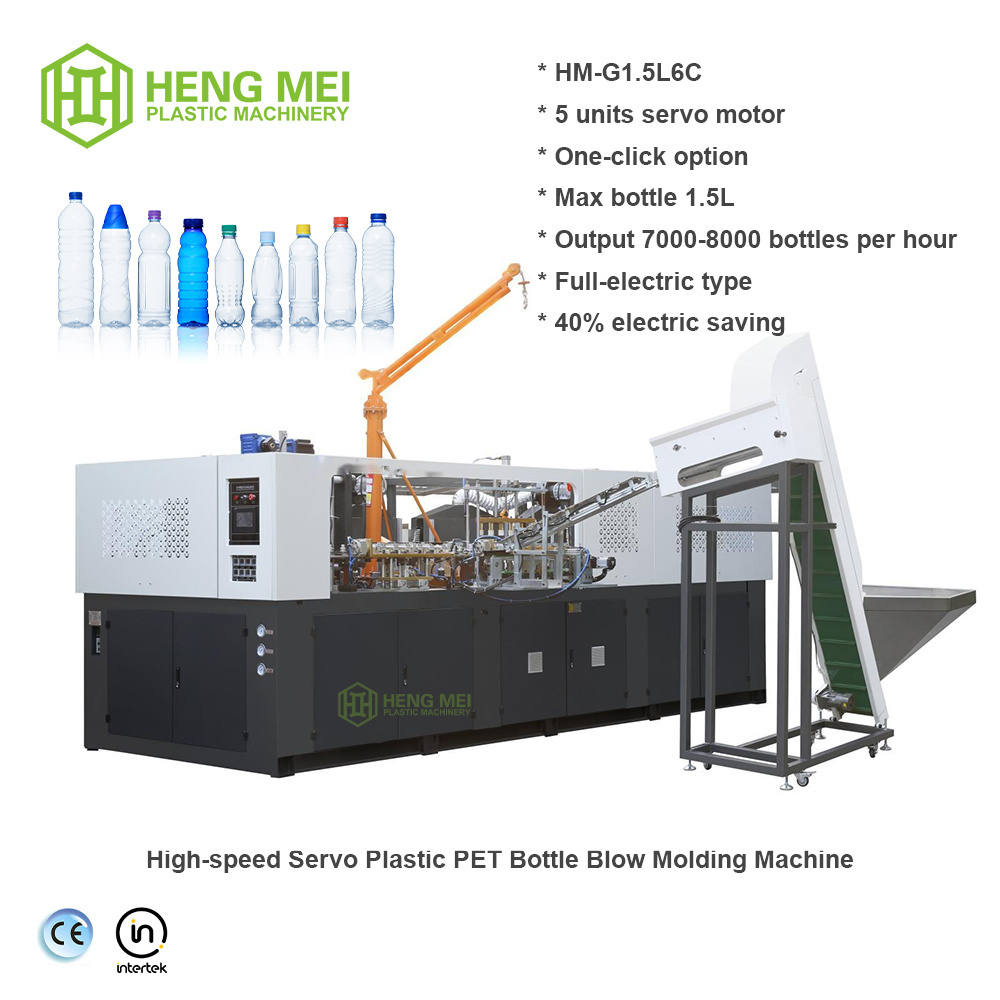

HM-G1.5L6C

|

HM-G0.6L6C

|

HM-G10L2C

|

HM-G15L2C

|

Others

|

|||||

|

Material

|

PET

|

PET

|

PET

|

PET

|

PET

|

|

|||||

|

Cavity

|

4

|

6

|

6

|

2

|

2

|

|

|||||

|

Volume

|

2L

|

1.5L

|

0.6L

|

10L

|

15L

|

|

|||||

|

Output (bph)

|

5000-6000

|

7000-8000

|

8000-9000

|

5L: 1800-2000

10L: 800-1000

|

/

|

|

|||||

|

Max neck size

|

26-98mm

|

15-38mm

|

15-38mm

|

38-55mm

|

38-55mm

|

|

|||||

|

Max height

|

360mm

|

360mm

|

260mm

|

330mm

|

330mm

|

|

|||||

|

Max diameter

|

100mm

|

105mm

|

68mm

|

220mm

|

220mm

|

|

|||||

|

Power

|

64KW

|

150KW

|

105KW

|

180KW

|

180KW

|

|

|||||

|

Machine size

|

4.9*1.9*2.2M

|

5.8*2.0*2.0M

|

4.8*2.0*2.0M

|

5.7*1.7*1.9M

|

5.7*1.7*1.9M

|

|

|||||

|

Machine weight

|

5T

|

5T

|

5T

|

5T

|

5T

|

|

|||||

|

|

For more models, please contact us.

|

|

|

|

|

|

|||||

Machine Detalis

Preform Loading System.

Each mechanical action has a safety self-locking device, and when a certain process malfunctions, the program will automatically switch to a safe state.

Preform Heating System.

Using infrared light tubes for heating, with strong penetration, the bottle preform rotates and is heated, and the track rotates,

Mold Clamping System.

The machine adopts a four template structure with double opening and double closing, saving mold locking time and greatly increasing machine output. This structure is independently developed by our company and has a domestic design patent;

Bottle Retrieval System.

Unique valve position design, each part of the blowing valve action valve adopts well-known domestic brands or imported foreign brands, with safe and reliable quality, and clear gas path at a glance; The production process is fully automated, with advantages such as low investment, high efficiency, easy operation, simple maintenance, and safety.

PLC Control System.

Adopting advanced microcomputer control system, stable performance; The production process is fully automated, with advantages

such as low investment, high efficiency, easy operation, simple maintenance, and safety; Bottle scrapping rate less than 0.2%.

such as low investment, high efficiency, easy operation, simple maintenance, and safety; Bottle scrapping rate less than 0.2%.

Blowing Mold.

Made by ourself mold department.

Main Configuration List

|

Electric Components

|

PLC

|

Japan Mitsubishi

|

|

|

Touch Screen

|

Japan Mitsubishi

|

|

|

Relay

|

Germany Schneider

|

|

|

Circult Breaker

|

Germany Schneider

|

|

|

Air Switch

|

Germany Schneider

|

|

|

Start Button

|

Germany Schneider

|

|

|

Two-position Switch

|

Germany Schneider

|

|

|

Scram Button

|

Germany Schneider

|

|

|

Power Supply

|

Germany Schneider

|

|

|

Praximity Switch

|

Japan Omron

|

|

|

Photoclectric Switch

|

Japan Omron

|

|

Air Filtration

|

Low Pressure Oil-water Separator

|

Germany Festo

|

|

|

Low Pressure Press-regulating Valve

|

Germany Festo

|

|

|

Low Pressure Lubricator

|

Germany Festo

|

|

Servo Motor

|

Displacement Servo

|

Taiwan Xinjie

|

|

|

Clamping Servo Motor

|

Taiwan Xinjie

|

|

|

Stretch Servo

|

Taiwan Xinjie

|

|

|

Preform Up-loader Servo

|

Taiwan Xinjie

|

|

Cylinders

|

Bottle-takeout Flipping Cylinder

|

Germany Festo

|

|

|

Preform-saparating Cylinder

|

Germany Festo

|

|

|

Manipulator

|

Germany Festo

|

|

|

High Pressure Blowing Valve

|

Germany Festo

|

|

|

High Pressure Exhaust Valve

|

Germany Festo

|

|

Valves

|

High Pressure One-way Valve

|

Germany Festo

|

|

|

Low Pressure Mufer

|

Japan SMC

|

|

|

High Pressure Mufer

|

Japan SMC

|

|

|

Low Pressure Operating Valve

|

Germany Festo

|

Why Choose Us

Taizhou Huangyan Hengmei Plastic Machinery Co., Ltd.

Taizhou Huangyan Hengmei Plastic Machinery Co., Ltd. is a new environmental protection and energy-saving machinery technology enterprise specialized in the design, development, production, sales and service of plastic packaging machinery. The main components of our bottle blowing machine are Mitsubishi PLC and touch screen, Schneider Electric, Xinbao reducer, Taiwan Xinjie servo motor, Taiwan Yade pneumatic accessories and other internationally famous products, which have the advantages of convenient operation, wide application range and low cost, and are suitable for blowing various forms of carbonated beverage bottles, mineral water bottles, pesticide bottles, cosmetics bottles, large-diameter bottles, medicine bottles, hot filling bottles, etc., which are drinks, candy, medicine, chemical packaging solutions for petroleum and other industries.

Our Serivce.

*7/24 Online Service:Machine running video / Watch our factory online / More service contact us

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

Hengmei Machinery Factory.

Certificate &Patent.

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in Hengmei Machinery.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Technology center.

HENGMEI Technology Center is a concentrated embodiment of design and technological excellence. Our technical experts develop a complete set of plastic packaging from the initial idea to the finished product. The basic principle is' everything comes from the same source '. Bringing numerous advantages to our customers:

* High quality packaging solutions to maximize customer satisfaction

*

Close cooperation and professional consultation

*

Contact points for all product development stages

*

Fast execution and high flexibility in changing situations

*

Globally applicable standards and latest technologies

*

Optimal early coordination based on production requirements

*

Developing and producing to achieve low cost and high efficiency

Global influence

.

We are able to collaborate with our customers and partners faster and more flexibly. We not only produce products for the market. We are still a part of the market. We have set up seven technology centers on four continents, and when customers need us for product and technology development, we are by our side.

FAQ

SEE HENGMEI MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF HENGMEI MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years.

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to Hengmei Machinery site.

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed & research team,we can send you engineers and make sure your after sales service.

HOW TO FIND HENGMEI MACHINERY?

● Search Alibaba,Google, Youtube and find suppliers and manufactrue and not traders.

● Visit exhibition in different countries.

● Send King Machine an request and tell your basic inquiry.

● Hengmei Machinery sales manager will reply you in short time and add instant chatting tool.

● Visit exhibition in different countries.

● Send King Machine an request and tell your basic inquiry.

● Hengmei Machinery sales manager will reply you in short time and add instant chatting tool.

Hot Searches