- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Requirement, 220V

-

Dimension(L*W*H):

-

Custom Made

-

Warranty:

-

1 YEAR, 1 year

-

Certification:

-

CE

-

Power:

-

Adjustable

-

Min order:

-

1 pc

-

Power(W):

-

5-600KW

-

Color:

-

Support customzied

-

Temperature Accuracy:

-

+/- 1 .C

-

Heating Element:

-

coils

-

Tilting:

-

hydraulic

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YIFAN

-

Model Number:

-

HTM/HTMM

-

Voltage:

-

Requirement, 220V

-

Dimension(L*W*H):

-

Custom Made

-

Warranty:

-

1 YEAR, 1 year

-

Certification:

-

CE

-

Power:

-

Adjustable

-

Min order:

-

1 pc

-

Power(W):

-

5-600KW

-

Color:

-

Support customzied

-

Temperature Accuracy:

-

+/- 1 .C

-

Heating Element:

-

coils

-

Tilting:

-

hydraulic

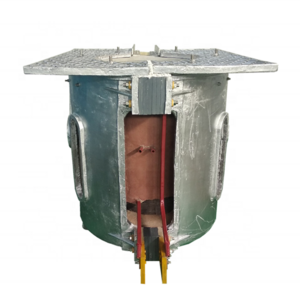

IGBT cast iron melting induction furnace

Description :

Better Heating penetration and even temperature inside the melting metal.

Induction field force can stir the melting pool to achieve better melting quality.

Melting the Maximum quantity by the recommend machine according to above table the melting time is 50-60 minutes, the first melting when the furnace is cold ,and it will take about 20-30minutes for the later melting when the furnace is already hot.

Suitable for melting of steel, iron, cooper, bronze, gold, silver and aluminum, stannum, maqnesium, stainless steel.

1.IGBT(INFINEON) technology, high conversion efficiency;

2.Energy saving 15%-30% , compared to SCR/KGPS technology Much more efficient than gas-fired and coal-fired method

100% start-up success rate; power factor > 95%

3.Perfect and complete protection functions, increasing machine's reliability & stability

4.No special foundations required, Low operating cost, Easy operation

5.Modular design, ease of maintaining and repairing

Standard induction furnace main parameter :

| NO |

Steel, iron, nickel, chromium |

Gold, silver |

Copper, tin, antimony, lead, zinc and germanium |

Aluminum, silicon, titanium and magnesium |

Voltage |

Input power |

melting time |

| HTM-15 | 200G | 2KG | 2KG | 500G | 220v | 7kw | ≤8minutes |

| HTM-25 | 500G | 3-5KG | 3-5KG | 0.5KG | 380v | 15kw | ≤8minutes |

| HTMM-15 | 2KG | 10KG | 10KG | 5KG | 380v | 15kw | ≤20minutes |

| HTMM-25 | 4KG | 20KG | 20KG | 10KG | 380v | 25kw | ≤20minutes |

| HTMM-35 | 8KG | 40KG | 40KG | 20KG | 380v | 35kw | ≤30minutes |

| HTMM-45 | 15KG | 60KG | 60KG | 30KG | 380v | 45kw | ≤30minutes |

| HTMM-70 | 25KG | 100KG | 100KG | 40KG | 380v | 70kw | ≤30minutes |

| HTMM-90 | 45KG | 120KG | 120KG | 50KG | 380v | 90kw | ≤30minutes |

| HTMM-110 | 60KG | 150KG | 150KG | 60KG | 380v | 110kw | ≤40minutes |

| HTMM-160 | 100KG | 180KG | 180KG | 75KG | 380v | 160kw | ≤40minutes |

induction furnace Main applications:

Heat treatment: Hardening, annealing, tempering of auto parts, motorcycles, hardware tools, gears, sprockets, pneumatic, hydraulic accessories.

Hot forming: Diathermy of small workpiece, hot forging and hot rolling of twist drill.

Welding: The welding of turning/woodworking tools, drill bits, serrated blade, steel, copper wall, similar metal.

Metal melting: (Vacuum) molding, casting molding and evaporation coating of gold, silver, Fe, Al and other metals.

Other applications: The production of semiconductor single crystal, with hot, bottle sealing, sealing toothpaste, powder coating, metal embedded in plastic and so on

Out Service:

One year warranty;

Long-term technical service;

Overseas on-site technicians service if required.

We have much stocks so we can arrange for the delivery very fast!

We believe "first quality,first customers,first service"

Sincerely provide service for you!