- Product Details

- {{item.text}}

Quick Details

-

Power:

-

user requirement;

-

Dimension(L*W*H):

-

user requirement;

-

Weight:

-

1000

-

Certification:

-

CE/ISO9001:2000/ROSH

-

Material:

-

SUS304/SUS316/Red copper

-

Control system:

-

PLC,HMI or Touch panel;Semi-automatic

-

Insulation:

-

Polyurethane or Rockwool with thickness=80mm~100mm

-

Cooling way:

-

Water belt/miller board

-

Heating method:

-

Electric/steam

-

Bottom cone:

-

60 or 75 degree

-

Payment Way:

-

TT,L/C,ONE-TOUCH,Trade Assurance

-

Application:

-

bar/pub/home/restaurant/hotel/commecial/brewing plant

-

Product Keywords:

-

Mash Tun,Lauter Tun,mash tun & lauter tun

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Supermax

-

Voltage:

-

Depends on size

-

Power:

-

user requirement;

-

Dimension(L*W*H):

-

user requirement;

-

Weight:

-

1000

-

Certification:

-

CE/ISO9001:2000/ROSH

-

Material:

-

SUS304/SUS316/Red copper

-

Control system:

-

PLC,HMI or Touch panel;Semi-automatic

-

Insulation:

-

Polyurethane or Rockwool with thickness=80mm~100mm

-

Cooling way:

-

Water belt/miller board

-

Heating method:

-

Electric/steam

-

Bottom cone:

-

60 or 75 degree

-

Payment Way:

-

TT,L/C,ONE-TOUCH,Trade Assurance

-

Application:

-

bar/pub/home/restaurant/hotel/commecial/brewing plant

-

Product Keywords:

-

Mash Tun,Lauter Tun,mash tun & lauter tun

Product Description

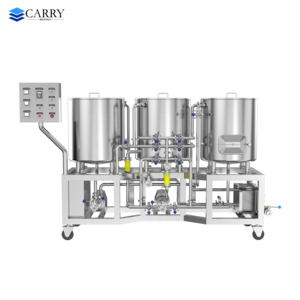

brewery equipment micro beer brewing equipment

Product description

product description

Brew process:

1). Malt Mill

The two roller mill crushes the malted barley to the desired coarseness.

2). Hopper(optional)

The hopper is used to hold the entire brew strength of grist (malt after milling)

3). Hot Liquor Tank

Used to recover energy and heat the water (liquor) needed for recirculation and sparging water onto the grain bed to convert starches to sugar.

4). Mash / Lauter Tun

Used to combine the grist and hot water. A false bottom is then used to extract the clear wort from the malted barley. The spent grains left over can be used for animal feed.

5). Diverter Panel and Transfer Pumps

Is used to transfer liquid flow from the mash / lauter tun to the kettle and then onto the fermenters. Designed with one person ease of use and cleaning in mind.

Detailed Images

6). Brew kettle / Whirlpool

The wort is boiled to a desired specific gravity and hops are added for flavor and bitterness. After boiling the wort is whirlpooled to collect soluble proteins (trub) in the center of the kettle. The clear wort is then pumped through the heat exchanger and into the fermenter.

7). Heat Exchanger

using city water and/or cold propylene glycol as cooling mediums the wort is cooled to an acceptable fermentation temperature, from 10 deg C(50 deg F) to 17 deg C(62.5 deg F), before it goes to the fermenter.

Fermentation system

8). Fermentation / Aging Vessel (open, closed or Unitank style)

The wort is pumped into this vessel and added to the previously pitched yeast and allowed to ferment (typically 3 to 7 days). The fermentation tank can be used as an aging tank or the beer can be transfered to a separate vessel for the aging period (typically 10 to 20 days).

Welcome you to visit our factory and check the quality of the equipment !

When the customer decide to come here,we can provide invitation,booking hotel,pick up,etc.

Certifications

Company profile

Jinan Supermax Machinery Co.,Ltd is a professional manufacturer of beer brewing equipment. We are specialized in brewery design, manufacture, installation and debugging for brewpub, bar, restaurant, microbrewery, reginal brewery etc.

With fine workmanship, excellent performance and simple operation. All details are taken the humanized and brewmasters' intention into consideration. Reliable quality is guaranteed by professional technical support, advanced processing equipment, strict qualit control and complete personnel training. Our engineers had been dispatched all over the world for brewery designing, installation, training and technical supporting.

SUPERMAX is a partner that you can trust. Let's work together to help you realize your brewing dream.

Packing & Delivery

LCL(Less Container Load)

1.Pack by EPE(Pearl Wool) 2.Cover by Plastic Film

3.Load in Wooden Case 4. Fix by Attaching Strap in the Case

5.Close by Nails&tight by attaching strap finally

FCL(Full Container Load)

1.Pack by EPE(Pearl Wool) 2.Cover by plastic film

3.Fix on the Iron frame attaching strap 4.Load onto the container

5.Fix the tank to the wall of container by attaching strap

1.Pack by EPE(Pearl Wool) 2.Cover by Plastic Film

3.Load in Wooden Case 4. Fix by Attaching Strap in the Case

5.Close by Nails&tight by attaching strap finally

FCL(Full Container Load)

1.Pack by EPE(Pearl Wool) 2.Cover by plastic film

3.Fix on the Iron frame attaching strap 4.Load onto the container

5.Fix the tank to the wall of container by attaching strap

Our Service

Our service

1) Free consultation service before, during, and after sales.

2) Project planning and design services.

3) Free debugging instruction of equipment until everything is functional.

Management of equipments' long distance shipping from seller's factory

4) to named port or station by buyer.

5) Training of equipment maintenance and operating personally.

6) New production techniques.

7) Provide 5 years complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage; All spare parts and wearing parts and wearing parts are attached with the machinery for free.

FAQ

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2.Is your goods has ISO9001 or CE certificate ?

Yes,all our goods has ISO and CE certificate. All machines are high quality goods.

3. Q: Are you a manufacturer?

We are the manufacturer of beer brewing equipment for more than 10 years.

4.Q: Can you do OEM or ODM?

Yes, we can do.

5.Q: How to control temperature ?

PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

6. Which export port you use?

Commonly we will use Qingdao port, sometime,it can appoint as you like.

7.How to use your machine?

We have paper instructions in English, and we will teach till you do it well.

8.How about the warranty?

All our equipment main part has 10 year quality warranty. And we provide life long time technical support, spare parts and other assistance.

Contact Us

Hot Searches