- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiyun

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5500*1200*1400

-

Weight:

-

1300 kg

-

Product name:

-

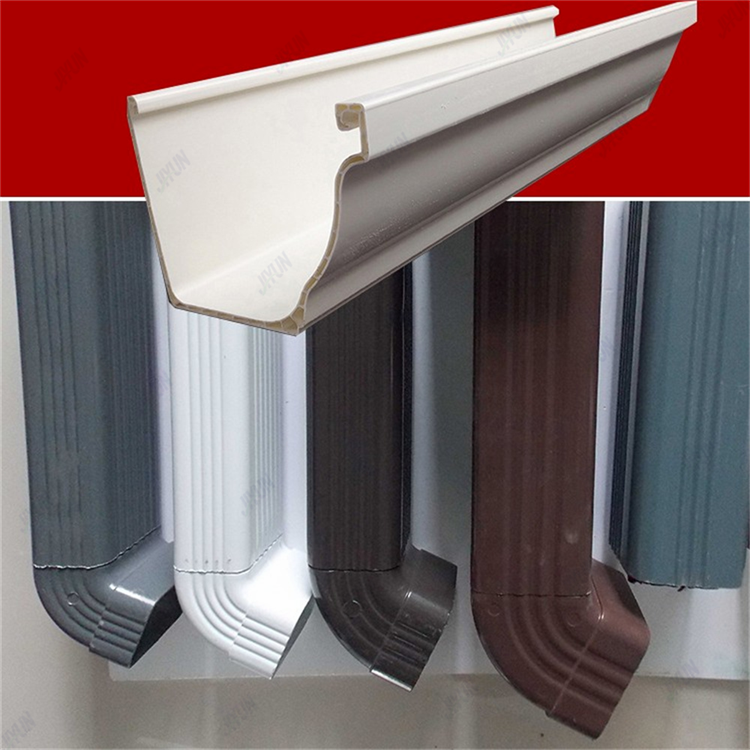

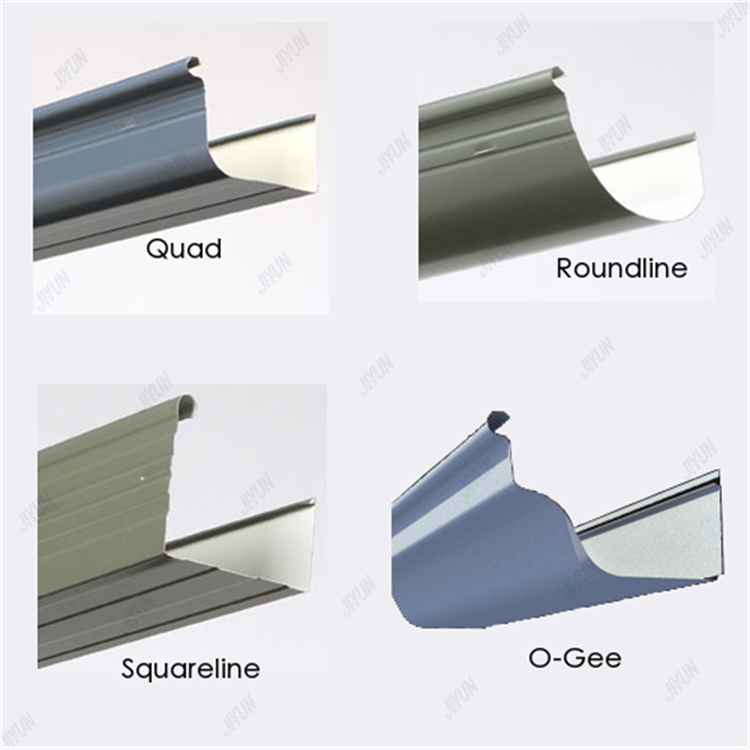

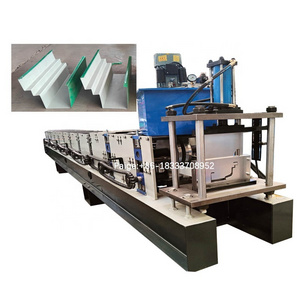

Rain gutter machine

-

Application:

-

Roof Sheet Production

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

Servo Motor Control System

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Mould Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Decoiler:

-

5T Manual Decoiler

-

Forming Speed:

-

15~25 M/min

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiyun

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5500*1200*1400

-

Weight:

-

1300 kg

-

Product name:

-

Rain gutter machine

-

Application:

-

Roof Sheet Production

-

Raw material:

-

PPGI PPGL GI GL

-

Control system:

-

Servo Motor Control System

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr12 Mould Steel

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Decoiler:

-

5T Manual Decoiler

-

Forming Speed:

-

15~25 M/min

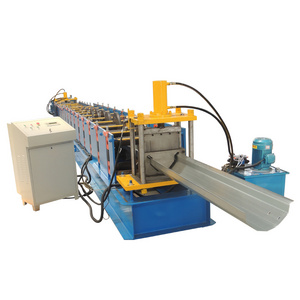

Products Description

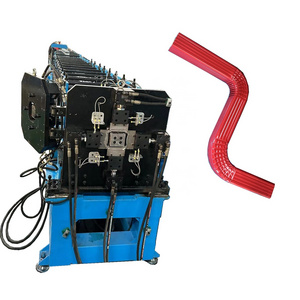

Rain gutter forming machine adopts advanced hydraulic drive, and the automatic ruler is cut off after forming, no deformation,no waste, and the safety factor is high (the main engine stops and cuts off). The rain gutter forming machine is equipped with a manual uncoiler, a forming host, a hydraulic cutter, an electronic control system, a hydraulic system, and a discharge rack for plate pressing.

Product Parameter

|

Item

|

Name

|

Quantity

|

|

1

|

Uncoiling Device

|

1 set

|

|

2

|

Forming Main Machine

|

1 set

|

|

3

|

Hydraulic Cutting System

|

1 set

|

|

4

|

Material Receiving Table

|

1 set

|

|

5

|

PLC Control System

|

1 set

|

|

6

|

Supporting Accessories

|

1 set

|

|

Item

|

Parts

|

Specification & Description

|

|

1.Raw Material

|

Type

|

GI / GL /PPGI / PPGL /Customization steel coil

|

|

|

Thickness(mm)

|

0.3-0.8

|

|

2.Un-coiler Device

|

Type

|

Inner contraction range

|

|

|

Max Loading(Tons)

|

5T/8T/10T(optional)

|

|

|

Way of working

|

Manual / Electric / Hydraulic tensioning crank.

|

|

|

Panel Width(mm)

|

940-1220mm(customizable)

|

|

|

Coil Inner diameter

|

φ480-500mm

|

|

|

Inner adjust range

|

φ450-550mm

|

|

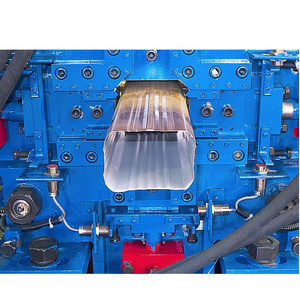

3.Forming Main Machine

|

Main frame

|

Material:300H/350H steel

Processing:Welding frame

|

|

|

Middle plate

|

Material : 45#steel

Thickness: 14mm Processing :laser cutting |

|

|

Shaft

|

Material : 45# steel with chrome 0.05mm

Diameter : 70mm Processing : Precision machining, heat treatment, precision grinding |

|

|

Rollers

|

Material: 45# steel Chrome Plated

Processing : Quenching, precision turning, polishing treatment |

|

|

Roller Station

|

10-16 stations or Customization

|

|

|

Transmission

|

Specifications:1 inch chain wheel with gear transmission

Processing :Quenching heat treatment Gear oil:18 # hyperbolic gear oil |

|

|

Main Motor

|

Power:5.5KW

Brand:Lichao(optional) Reducer: Cycloidal reducer Protection level:IP55 Explosion-proof level:ExdIICT4 |

|

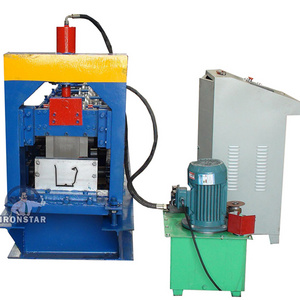

4.Cutting System

|

Type

|

Automatic Hydraulic Cutting

|

|

|

Blade material

|

Cr12MOV heat treatment process

|

|

|

Pump

|

hydraulic pressure:10-12mpa

Hydraulic oil: 46# |

|

|

Pump motor for cutter

|

Power: 4KW

|

|

5.Receiving rack

|

Type

|

manual / Electric receiving rack

|

|

6.PLC Control System

|

PLC Control System

|

Plc brand:Delta (optional)

Text control box:Vertical LCD touch screen control box/Swing arm LCD touch screen control box Language: English / Chinese / Customized |

|

|

Inverter

|

Rated power:7.5KW

|

Details Images

Hot Searches