- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Skyasia

-

Input Voltage:

-

AC 110-240V

-

Output Temperature:

-

200-450℃/392-842°F

-

Temperature Stability:

-

±2°C

-

Output Power:

-

60w

-

Dimensions:

-

19 cm/7.48 inches

-

Weight (KG):

-

1 KG

-

Power (kW):

-

60W

-

Product name:

-

Soldering Iron Kit

-

Application:

-

Soldering/Repair Tools

-

Feature:

-

Temperature Control

-

Working Voltage:

-

AC 220V/50Hz 110V/60Hz

-

Soldering Iron Color:

-

Blue

-

Heater:

-

Ceramic Heating Element

-

Soldering iron switch:

-

Optional

-

Soldering Tips:

-

I K B 3C 1.6D (other can be Customizable )

-

Pulg:

-

US AUS EU UK etc(Customizable)

-

Customize:

-

Yes

-

Certification:

-

CE,FCC

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

Core Components:

-

Consumables and accessories are not warranted

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Skyasia

-

Input Voltage:

-

AC 110-240V

-

Output Temperature:

-

200-450℃/392-842°F

-

Temperature Stability:

-

±2°C

-

Output Power:

-

60w

-

Dimensions:

-

19 cm/7.48 inches

-

Weight (KG):

-

1 KG

-

Power (kW):

-

60W

-

Product name:

-

Soldering Iron Kit

-

Application:

-

Soldering/Repair Tools

-

Feature:

-

Temperature Control

-

Working Voltage:

-

AC 220V/50Hz 110V/60Hz

-

Soldering Iron Color:

-

Blue

-

Heater:

-

Ceramic Heating Element

-

Soldering iron switch:

-

Optional

-

Soldering Tips:

-

I K B 3C 1.6D (other can be Customizable )

-

Pulg:

-

US AUS EU UK etc(Customizable)

-

Customize:

-

Yes

-

Certification:

-

CE,FCC

Products Description

Multifunctional 60Watt Soldering Tools With Glue Gun,Skyasia Temperature Controlled Electric Soldering Iron Kit Set

|

Soldering Iron Kit Specification

|

|

|

|

|

||||

|

Product Name

|

|

Soldering Kit

|

|

|

||||

|

Feature

|

|

Soldering,Carving,Pyrography,Repair,DIY

|

|

|

||||

|

Input voltage

|

|

110-240V

|

|

|

||||

|

Power

|

|

60W

|

|

|

||||

|

Package size

|

|

27*18*5cm

|

|

|

||||

|

Package includes

|

|

1 * Soldering iron (220 V, 60 / European Plug W, 110 V, 60 W, US Plug

1 * Carving Knife (14 cm)

1 * Screwdriver (contains 4 Replacement screws)

10 * Glue Pieces D7 * 100mm

5 * Soldering iron tip

1 * Glue gun (100 V to 240 V, 20 W, European plug)

1 * Soldering iron stand

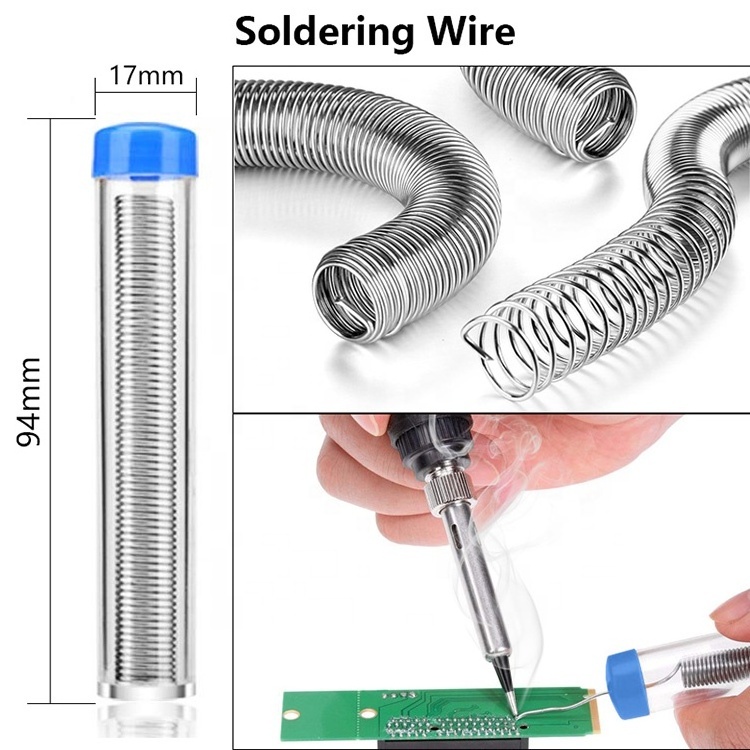

1*Solder wire (1 x cable Diameter: 1mm, 10g)

1 * Desoldering Pump

1 * Tweezers

1 * Nylon Bag

|

|

|

||||

How to use electric soldering iron and matters needing attention:

1. Before using the new soldering iron, apply fine sandpaper to brighten the soldering iron tip, turn it on and heat it up, dipped in rosin, and touch the soldering wire with the blade surface of the soldering iron tip to make a layer of tin evenly plated on the soldering iron tip. Doing so can facilitate soldering and prevent the surface of the soldering iron tip from oxidizing.

2. It is strictly forbidden to repair the alloy head. If it is found that it is not tinned, it can be used after activation with flux.

3. The soldering iron should be kept dry, and it is strictly forbidden to work in a humid environment.

4. Before use, check the power plug and power cord for damage and check whether the voltage is consistent. And check whether the soldering iron tip is loose.

5. Do not strike hard when using the soldering iron. To prevent falling. If there is too much solder on the tip of the soldering iron, wipe it off with a cloth. Don't shake it indiscriminately to prevent scalding others.

6. During the soldering process, the soldering iron should not be placed everywhere. When not soldering, it should be placed on the soldering iron stand. Note that the power cord should not be placed on the tip of the soldering iron to prevent accidents caused by scalding the insulating layer.

7. After use, the power should be cut off in time and the power plug should be unplugged. After cooling down, return the soldering iron to the toolbox.

8. Remove the soldering iron tip after several times of use, and remove the oxide layer, so as to prevent the oxide layer from being blocked in the future and the soldering iron tip cannot be removed.

Basic skills of using electric soldering iron:

1. Choose suitable solder, and use low melting point solder wire for soldering electronic components.

2. Flux, use 25% rosin dissolved in 75% alcohol (weight ratio) as a flux.

3. The electric soldering iron should be tinned before use. The specific method is: heat the electric soldering iron, and when the solder can be melted, apply flux, and then apply the solder evenly on the tip of the soldering iron to make the tip of the soldering iron evenly eaten. One layer of tin.

4. The soldering method, polish the pads and component pins with fine sandpaper, and coat them with flux. Dip a proper amount of solder with a soldering iron tip and touch the solder joints. After the solder on the solder joints are all melted and immersed in the component leads, the soldering iron tip is gently lifted up and away from the solder joints along the component pins.

5. The soldering time should not be too long, otherwise the components will be easily burned. If necessary, use tweezers to clamp the pins to help dissipate heat.

6. The solder joints should be in the shape of sine wave peaks, and the surface should be bright and smooth, free of tin thorns, and moderate tin quantity.

7. After the soldering is completed, use alcohol to clean the residual flux on the circuit board to prevent the carbonized flux from affecting the normal operation of the circuit.

8. The integrated circuit should be soldered last, and the electric soldering iron should be grounded reliably, or the residual heat should be used for soldering after power failure. Or use dedicated sockets for integrated circuits, and then plug in the integrated circuits after soldering the sockets.

9. The electric soldering iron should be placed on the soldering iron stand

Hot Searches