- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

NONE

-

Place of Origin:

-

China

-

Brand Name:

-

HECHNEG

-

Model Number:

-

HC-100C

-

Type:

-

Polyurethane Adhesive

-

Product name:

-

1-component adhesive

-

Application:

-

for bond rubber and other materials

Quick Details

-

CAS No.:

-

NONE

-

Other Names:

-

Polyurethane Adhesive

-

MF:

-

NONE

-

EINECS No.:

-

NONE

-

Place of Origin:

-

China

-

Brand Name:

-

HECHNEG

-

Model Number:

-

HC-100C

-

Type:

-

Polyurethane Adhesive

-

Product name:

-

1-component adhesive

-

Application:

-

for bond rubber and other materials

Propreties :

S olvent free, high initial adhesion strength, scratch resistance, hydrolysis resistance.

Adjust processing, pot life, curing time according to specific requirements.

Application:

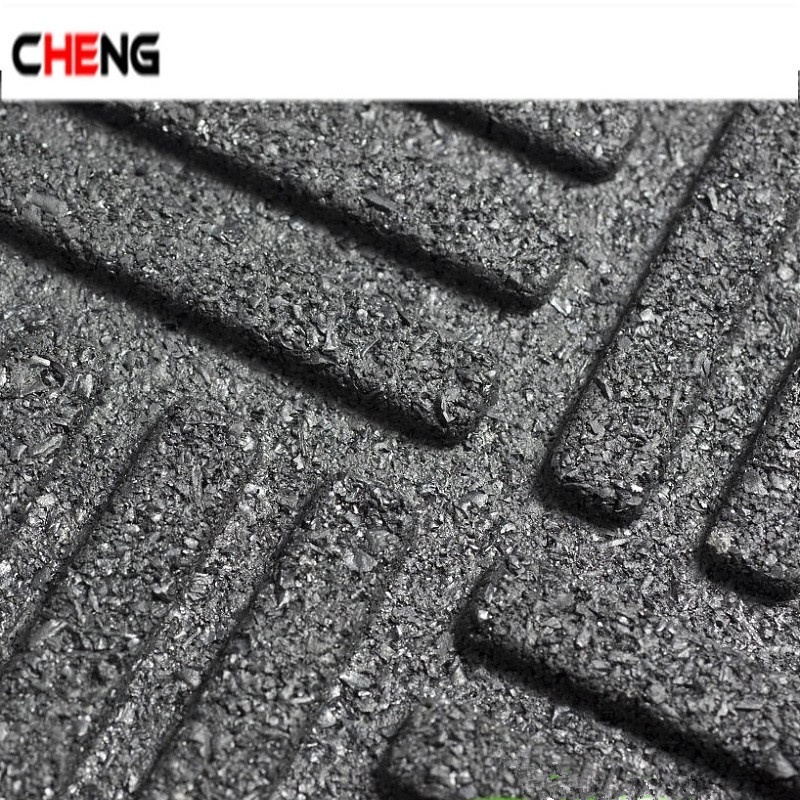

It can be used to bond rubber and other materials.

Recommend material:

HC-100C,HC-100E,HC-8678AB

Environmentally friendly solvent-free polyurethane adhesive HA-100C

Nature of components: Solvent-free environmentally friendly adhesive, 100% without solvent, after drying, the adhesive with excellent adhesive strength, excellent scratch resistance and super water resistance.

Applications: It is widely used in the bonding of rubber and organic materials.

Properties of material:

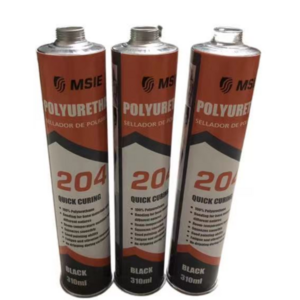

Name of products Standard

Appearance at room temperature/ 25℃: slightly yellow viscous liquid

Viscosity(cps/25℃): 3000±1000mpa.s/25℃

NCO %: 12.0±0.5

Package: 20 kg/drum

Processing way:

These instructions apply to our adhesive products.

1) Apply adhesive uniformly to the surface of a clean and dry substrate by scraping or roller coating.

2) If allowed, it can be cured by curing at 90-140℃ for about 40 minutes, and it can be left to achieve the room temperature.

3) If it is placed and cured at room temperature, the curing time can be about 3-4 hours in an environment with temperature 25 ° C

and with humidity above 50%.

4) If the temperature and humidity are relatively low, In the absence of heating conditions, it is recommended to add the curing

agent provided by our company. The amount of curing agent is 1 to 10%, and it can be added if necessary.

5) If higher bonding strength is required, an appropriate amount of curing agent should be added.

6) If you need to reduce the viscosity during use, please use it with common polyurethane solvents (such as ethyl acetate, butyl

acetate, toluene, xylene, cyclohexanone, etc.), but the water content of the solvent is less than 0.1%.

NOTICE:

1.Prepolymer should be stored at low temperature and dry place, avoid moisture and water when using. Heating at higher

temperatures (over 75 ℃) should not exceed 3 hours.

2.Adhesive should be used up as soon as possible after opening (Usually in 1 month should be used one drum 20KG ). Fill in

Nitrogen to seal if it can not be used up.

3.The shelf life of the unopened adhesive is one year.